ABERDEEN PROVING GROUND, Md. -- Two Marine support programs are making due with fewer of the deployable facilities they have come to rely upon, yet neither one is complaining.

For the past decade the Marine Corps Systems Command, has collaborated with the Army's Communications-Electronics Research, Development and Engineering Center, or CERDEC, to design and integrate deployable shelter facilities for its Combat Camera and weapons calibration repair programs, respectively.

The latest prototypes have consolidated everything these Marines require to perform their missions into fewer prototyped shelters, resulting in a smaller, expeditionary footprint yet delivering much more space--and cutting-edge technologies--on the inside.

"We are extremely pleased that our continued partnership with the Marines has produced state-of-the-art facilities for these two critical Marine Corps functions," said Christopher Manning, chief of the CERDEC Command, Power and Integration Directorate's Prototype Integration & Testing Division.

The PI&T manages and operates the Prototype Integration Facility, or PIF, which provides engineering design, development, fabrication, installation, integration and fielding support for shelter, vehicle, aircraft, watercraft and Soldier prototype command, control, communications, computers, intelligence, surveillance and reconnaissance, or C4ISR, systems.

The Tactical Imagery Product System, or TIPS, processes images and video collected from the battlefield to provide intelligence and situational awareness to the Marine Expeditionary Force Combat Commander for command and control decision making.

The TIPS redesign reduces the number of shelters from two hard-sided shelters to one expandable shelter, and was created in response to the Marine Corp commandant's guidance to shrink the expeditionary footprint but still retain the same Combat Camera services.

"When CERDEC first came up with the TIPS concept, everyone said it would be impossible to do," said Capt. Keith Stevenson, Combat Camera Systems Project Officer, U.S. Marine Corps Systems Command. "Now that we are on version three, we know that the engineers were able to look beyond the doubt to make it a reality."

The initial skepticism came from fears that some of the Combat Camera equipment would never be able to withstand the rigors of transportation in an austere environment. The PIF engineers' design and integration insertions, such as the rolling frames that secure the equipment while in use and during transport, have ensured those fears did not materialize.

"Copiers are notoriously fickle, even in an office environment, but these rolling frames act as shock absorbers," said John Ruroede, TIPS project lead.

In addition to the robust physical design, TIPS has redundancy of all major functions. For example, the workstations used in TIPS has hardware and software that is identical to another Marine Corps project called Visual Information Imagery Editing System, or VIIEs. If one of the three workstations goes bad, a VIIES computer can be used as a replacement. The modular network and multi-media cases allow for seamless system upgrades.

The new TIPS prototype includes cutting-edge multi-media equipment, multi-use copiers and a large scale production plotter, which take up less space and energy than the previous version. Engineers designed a new environmental control distribution system to provide a more even distribution of air conditioning and heat that draws half of the power of the existing TIPS, and the LED light fixtures also save energy consumption.

The TIPS prototype shelters are deployed at Marine Corps Bases Pendleton, Lejeune, and Quantico and Marine Corps Air Station Miramar with systems currently deploying to Okinawa, Japan and Marine Corps Air Station Cherry Point, North Carolina.

"We love the relationship we have with CERDEC because they are very responsive," Stevenson said. "From my perspective, they are also very conscious of how they utilize funds because they want to do things that are responsible for the taxpayer, such as reusing and refurbishing equipment when possible."

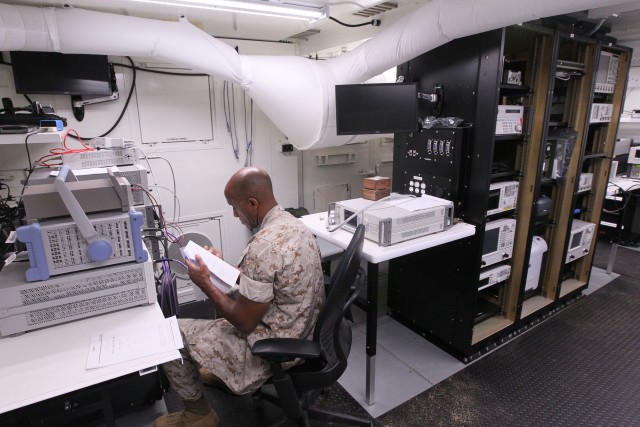

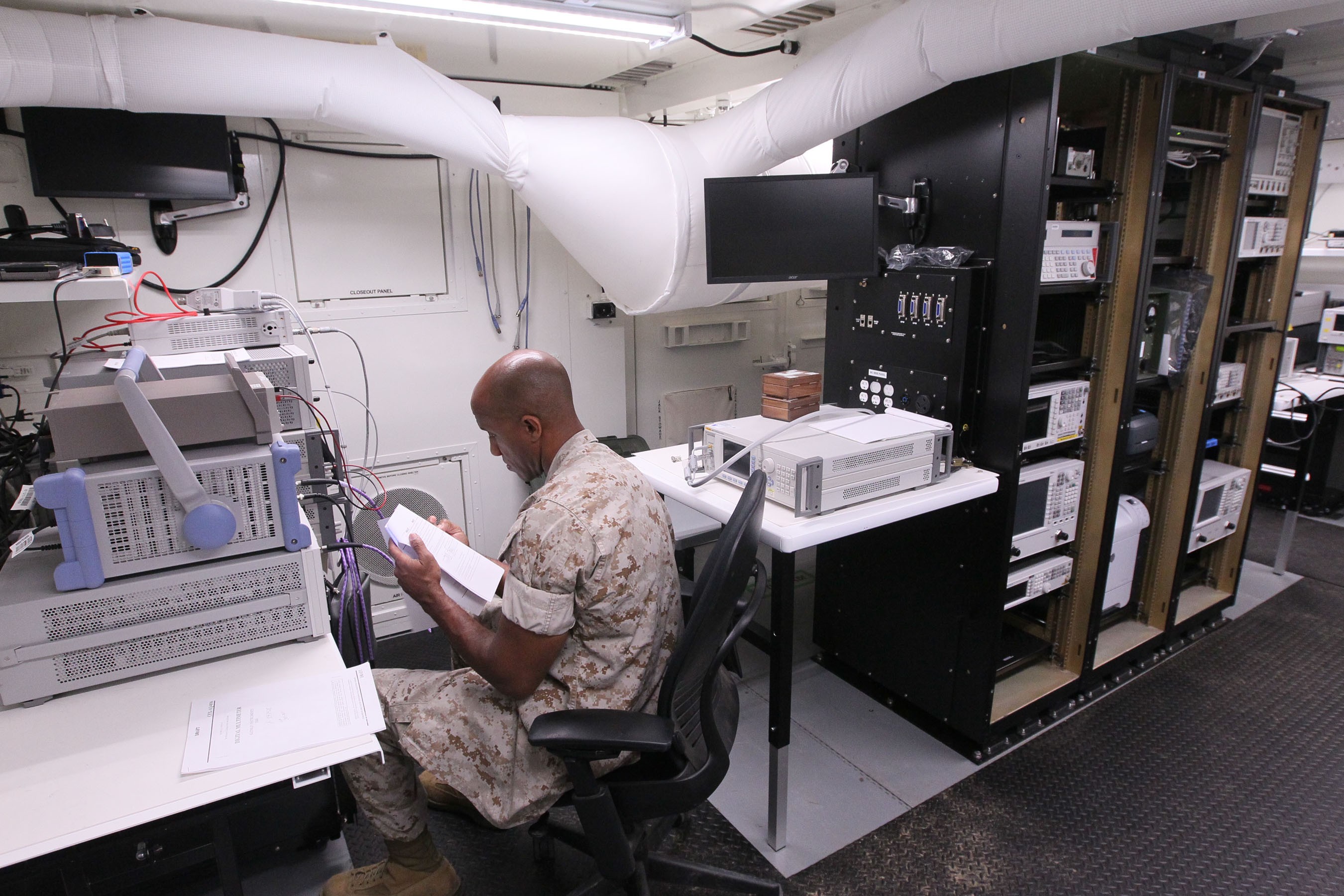

Expandable shelter designs are also benefitting the Marines' weapons calibration and repair facilities, or CALFAC. Mobile calibration systems provide Marines with precise measurements to ensure quick turn-around repairs, rather than lose critical time by shipping weapons back to the U.S. The latest CALFAC prototype features two tri-wall expandable hard shelters versus the previous version, which had four 20-foot Electromagnetic Interference, or EMI, shelters. The updated configuration reduces the footprint by nearly 45 percent, yet produces more than 33 percent additional floor space.

"The previous prototype only had enough room for three Marines to work comfortably in each shelter at once, so you would have a total of 12 Marines per overall facility," said Dan Llanes, CERDEC CP&I TIPS mechanical engineer. "Conversely, the latest prototype is large enough for seven Marines to work, which increases the capacity to 14 Marines per facility."

PIF engineers capitalized on the shelter's extra space by designing and integrating the interior with modular designs, such as rolling mounts for the equipment, detachable racks and collapsible counters and tables for optimal workflow and accessibility to equipment for maintenance. As with TIPS, the flexible design also allows the equipment to store securely in the shelter's middle section, which is critical for today's expeditionary missions.

"It is amazing how innovative the CERDEC team was in finding ways to reduce weight without losing capability," said James Durham, Calibration Project Officer, Marine Corps Systems Command.

PIF engineers configured the space to use up nearly every square inch once the shelter collapses to one third its size to ensure the calibration equipment remains stable, and many of the shelter's components are color coded for ease of set up and tear down, which is critical for the expeditionary nature of the Marine's missions, Llanes said.

Engineers also built the interior components using lighter materials, such as aluminum, instead of the steel or wood used in the previous version, to meet strict payload. In addition, each facility had to meet precise temperature control guidelines -- within plus or minus three degrees when calibrating -- so engineers also installed new environmental control units.

"Combining the shelters into one complex allows the calibrators to have more control of their environmental factors, such as temperature and humidity, inside the system," Durham said.

The Marines and PIF engineers continue to identify possible enhancements to the systems, and new prototypes for each facility are currently in the design phase.

"The work being done at the PIF is not just about bending metal," said Gary Blohm, CERDEC CP&I director. "It is about system engineering and collaborating with our customers, and TIPS and CALFAC are two of the exciting deliverables we have produced using this approach."

------

CERDEC is part of the U.S. Army Research, Development and Engineering Command, which has the mission to ensure decisive overmatch for unified land operations to empower the Army, the joint warfighter and our nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Links:

Rapid prototyping leads to airborne command post solution

Enabling command post capabilities from the hatch or at the halt

A two-for-one device houses the right radio at the right time

U.S. Army Research, Development and Engineering Command

Army.mil: Science and Technology News

U.S. Army Communications-Electronics Research, Development and Engineering Center

Social Sharing