The reality of shrinking budgets for the Army demands innovative acquisition approaches to ensure that Soldiers get the capabilities they need. One area that the Product Manager Sets, Kits, Outfits and Tools (PdM SKOT) is focusing on is understanding and balancing the commercial and organic industrial bases, but it is not always easy to decide between their two very different production capabilities in a way that best serves Soldiers and taxpayers alike.

PdM SKOT, assigned to the Project Manager (PM) Force Projection of Program Executive Office Combat Support and Combat Service Support, recognized this challenge and developed a process to improve analysis of competition between Army arsenals or depots and commercial manufacturers for new acquisition and re-procurement programs. This new process responds to Title X U.S. Code, Section 4532, "Factories and arsenals: manufacture at; abolition of," known as the Arsenal Act. It requires that supplies be made at government facilities if those facilities can produce on an "economical basis." While the law seems straightforward, interpreting it can be challenging for acquisition professionals. That's because of the relative difficulty in accurately comparing commercial manufacturing sources to organic arsenals and depots, and justifying an organic source as being capable of economical production.

A May 2, 2013, memo, "Using Army Arsenals," from Heidi Shyu, assistant secretary of the Army for acquisition, logistics and technology (ASA(ALT)), also highly encourages program managers to use the organic industrial base when possible. Army Regulation 700-90, "Army Industrial Base Process," further clarifies that AL&T professionals shall meet the intent of the Arsenal Act by performing a "make or buy" (MoB) analysis, but it provides no exact methodology for a MoB decision. In an attempt to fill this gap, PdM SKOT developed a process aimed at providing sound, step-by-step guidance for Army AL&T professionals implementing MoB decisions.

A RIGOROUS PROCESS

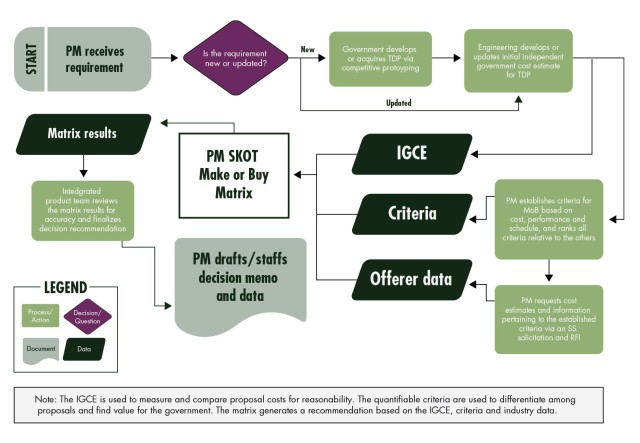

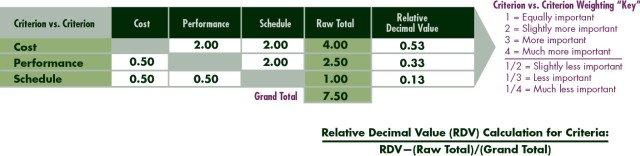

PdM SKOT's solution is a rigorous analytical process modeled after the basic logic from Defense Acquisition University (DAU) guidance for source selection boards (SSBs). PdM SKOT and key program stakeholders further defined specific criteria with regard to program cost, performance and schedule, and created a prioritization matrix to assess alternatives. (See Figure 1.)

The SSB process was helpful in providing an established, accepted methodology for selecting between commercial manufacturers. PdM SKOT applied it to a new process.

The MoB process begins when the program office receives a requirement for procurement. If the requirement is new, acquisition professionals must either internally develop or acquire, via competitive prototyping, a full, manufacturable, technical data package (TDP). The government then can use the TDP to create an independent government cost estimate (IGCE).

Next, the team must establish quantifiable, meaningful criteria and sub-criteria based on program needs. These criteria form a mathematical matrix used to compare offers directly and to strip away bias and emotion from the decision-making process. As with the source selection process, the PdM SKOT MoB criteria do not focus solely on the lowest-cost bid for the program. In the case of PdM SKOT, the purpose of the criteria and sub-criteria is to judge an offeror's ability to meet program needs with regard to cost, performance and schedule. For example:

• Cost--Criteria should, at a minimum, include an out-the-door cost for each item. Depending on the complexity of the program, a full breakdown of material and direct labor is preferable.

• Schedule--Criteria are easily quantifiable and should include questions regarding lead times and production capacity per fiscal year:

o Does the offeror have the ability to produce X number of completed assets in FY15?

o How many months of lead time are needed before delivery of the first completed asset?

• Performance--Criteria are listed as yes-or-no questions and quantified as binaries, with one point for "Yes" and zero points for "No."

o Does the offeror have the ability to store X number of completed assets?

o Does this offeror have experience or past performance that is relevant to the program?

Then, PdM SKOT requests cost and additional data based upon the established matrix criteria and sub-criteria through a nonbinding sources-sought (SS) solicitation to industry and a request for information (RFI) to organic manufacturers. The SS and RFI require the offeror to submit cost data and answer questions derived from the PdM's sub-criteria. PdM SKOT uses the cost and questionnaire data in the analysis to differentiate offers, which helps provide the PdM with the appropriate justification for the final MoB decision.

To ensure fairness, the PdM provides offerors from both organic facilities and commercial industry with the same questionnaire and TDP, along with specific instruction on assumptions that may be made. Acquisition professionals instruct offerors to bid on a specific, low quantity for production to prevent offerors from claiming unreasonable cost savings or economies of scale. The SS or RFI is further structured to clearly define and restrict the way an offeror must bid, to allow for as direct a comparison between offerors as possible.

WEIGHTED RESULTS

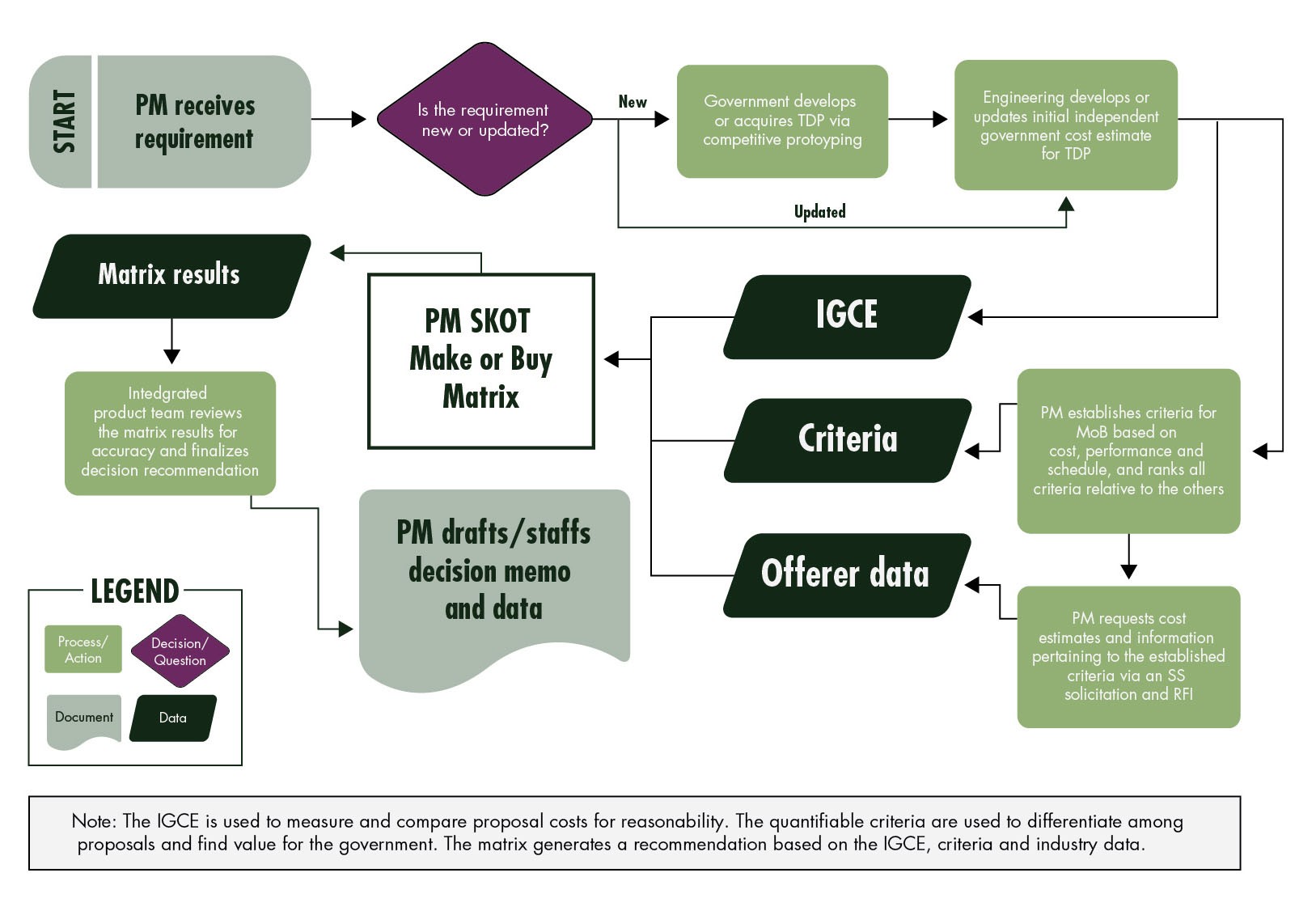

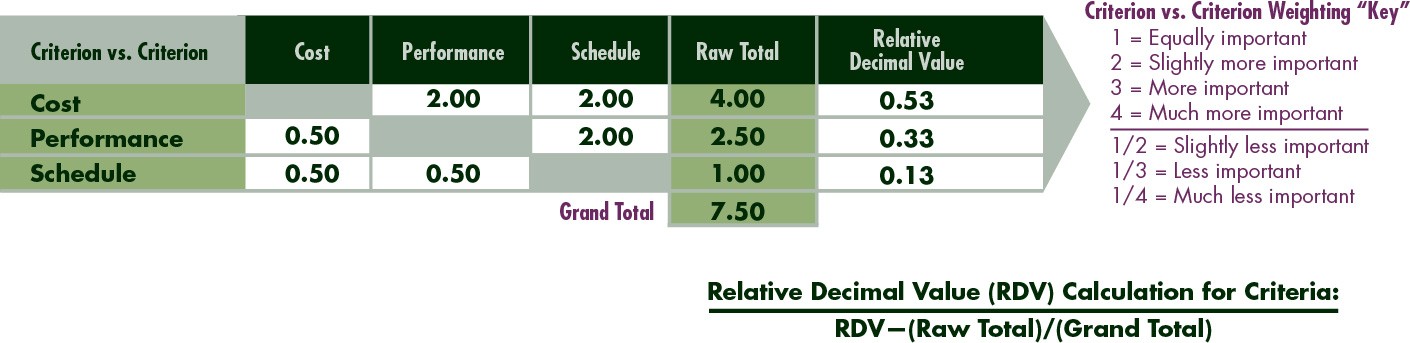

Before receiving SS and RFI data, the PdM weights the main cost, performance and schedule criteria in accordance with the needs of the program. (See Figure 2.) For example, the acquisition team may emphasize cost criteria heavily, although performance and schedule criteria are still included to measure and mitigate program risk.

Acquisition professionals then use data from the SS and RFI process to assess the MoB alternatives by employing the full analytical criteria method. This method is appropriate when there are few alternatives from which to choose and/or few criteria to evaluate, and the stakes are high if the project fails.

The next step is to calculate cost criteria scores using the raw data. Obvious statistical outliers, which include bids that do not account for basic hardware costs or are more than twice the IGCE, are immediately removed from the analysis. Offers then are judged based on their relation to the IGCE and each other. The raw numbers are converted to percentages (percentage above and percentage below the IGCE baseline) and into whole numbers. Scores that are more than 25 percent above or below the baseline are considered risky and are penalized heavily in the final analysis.

The product team calculates performance and schedule criteria scores by totaling the quantified answers to the SS/RFI questionnaire, and translates scores into their RDVs for direct comparison to other offerors' scores in the final analysis.

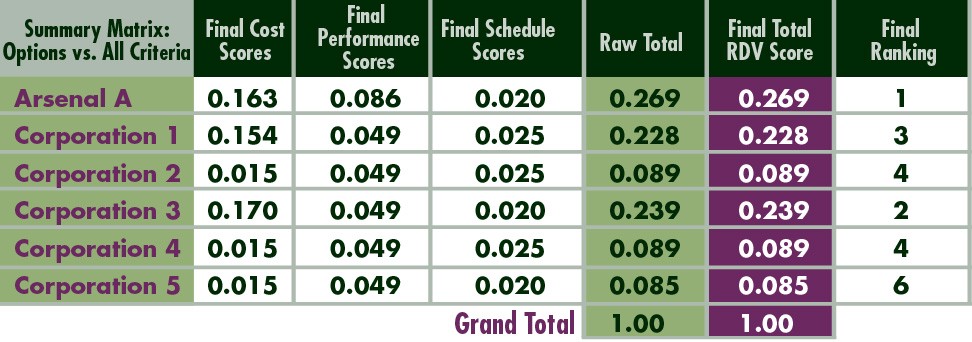

Final offeror scores are calculated based upon the PdM's criteria weighting. (See Figure 3.) Raw data entered into the matrix automatically provide a recommendation for the program to either buy commercially or make organically. The PdM team reviews the process for accuracy and makes a formal recommendation to the Milestone Decision Authority (MDA) based on the matrix findings.

CONCLUSION

This new process represents a positive, useful step in better understanding and leveraging the industrial base. In the past, we did not have a good process to consider using organic manufacturers, instead soliciting only commercial industry for work. This path routinely provided--and often still provides--appropriate capability, competition and a successful program. However, it often left acquisition professionals unable to even consider organic options that take advantage of facilities already owned by DOD. Organic options can help to ensure a more ready workforce at each arsenal and depot as needed for specialized, surge or contingency production missions.

To date, multiple PdM SKOT new-start programs have been designated as "make" items under this process because of the ability to analyze competition better. Competition, after all, is the acquisition professional's greatest tool to drive best value.

PdM SKOT's new process enhances competition by improving the Army's ability to understand the broader industrial base and compare its organic manufacturing facilities with commercial industry. Commercial sources will still often prove the more economical option, but today's acquisition professionals have a new tool to competitively seek the best value for our taxpayers and best capability for our Soldiers.

For more information, go to www.peocscss.army.mil.

Related Links:

U.S. Army Acquisition Support Center

Program Executive Office Combat Support and Combat Service Support

Social Sharing