FORT RUCKER, Ala. (August 15, 2013) -- Fort Rucker's Aviation Center Logistics Command was recently awarded the Air Conservationist of the Year award by the Alabama Wildlife Federation Governor's Conservation Achievement Awards Aug. 2 in Prattville for its implementation of the Spray Technique Analysis and Research for Defense program.

"The Aviation Center Logistics Command at Fort Rucker has the mission to provide superior maintenance on helicopters and ground services equipment, and at the same time, these services must be conducted safely and insure the integrity of the work and natural environment," read an AWF press release. "(ACLC) is preventing the unnecessary exposure of employees to hazardous materials and the unnecessary generation of hazardous waste and volatile organic compound emissions to the environment through incorporation of the STAR 4D painter training program."

The honor and effort isn't from any single person or even organization, said Col. Michael C. Aid, ACLC commander, but the efforts of many.

"ACLC is honored to be recognized, but this was really a team effort," he said. "ACLC has an environmental team on site that is matrix support from Aviation and Missile Command G4."

The team ensures that ACLC and contract partners, such as Army Fleet Support, comply with all environmental goals and objectives, but it was the garrison that noticed the efforts of ACLC and its partners.

Each year, the Alabama Department of Environmental Management hosts nominations for the AWF awards, and the Fort Rucker garrison nominated ACLC for the award, according to Genie Jones, AMCOM G4 ACLC environmental group leader.

"That just shows the team effort of the entire installation because we all do work very closely for our efforts," she said. "It puts a smile on your face because recognition is always nice, but the fact that others that we work with recognize that we've done something right and done something good for us, as well as the community, is nice."

Although the recognition is nice, said Jones, the efforts behind them aren't for recognition, but for sustainability of resources and conservation.

"We have limited resources, and in today's world those resources aren't just environmental resources -- it's financial resources as well," she said. "If we can find ways to continue what we're doing, grow what we're doing, grow with the mission and not increase any costs or resources, to me, that's what sustainment is and that's why it's important to the Army."

Part of that process was the implementation of the STAR 4D program, added Aid.

"The command determined that consistent quality painter training techniques and methods were critical to meeting the expanding mission set, as well as changing environmental and safety requirements," said the ACLC commander. "Implementation of this program improved painter skills while also improving quality controls to generate less hazardous waste, consume less coating materials and improve corrosion prevention on aircraft."

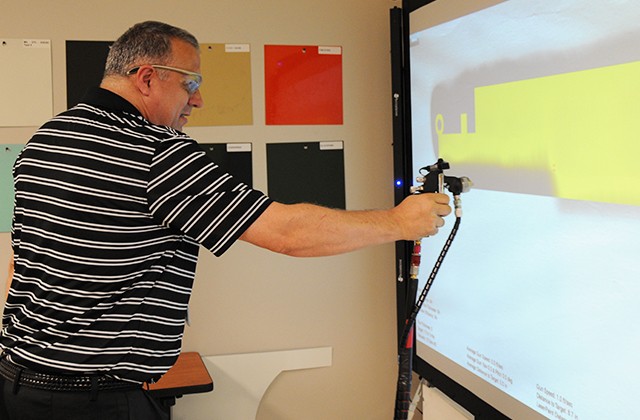

STAR 4D is a paint-training program that ACLC has had in place for about a year that utilizes state-of-the-art virtual reality technology to simulate the application of paint to various surfaces, and recent upgrades even allow the program to account for waste management and much more, said Tom Elsbernd, technical trainer for Army Fleet Support and certified Star4D instructor.

"The upgrades were quite intensive," he said. "The virtual reality machine brings into reality exactly what painters are doing in the field."

The program allows painters and instructors to dial in variables such as pressure of the gun, pressure of the pot, paint tip size, viscosity of the paint, and even data of the exact paint that would be used on aircraft, so that things like waste, overspray and costs can be calculated.

So far, the program has eliminated more than 10,000 pounds of hazardous waste, reduced coating materials by more than 300 gallons, reduced volatile organic compound emissions by more than 13 percent, and generated an estimated annual cost avoidance of $49,990 in operations costs, said Aid.

Related Links:

USAACE and Fort Rucker on Twitter

Social Sharing