NATICK, Mass. (March 15, 2012) -- Logistics, often perceived as an afterthought, is at the forefront of the Army's efforts to equip Soldiers with what they need in the manner that will assist them best.

When U.S. Army Research, Development and Engineering Command, Natick Soldier Development and Engineering Center Quick Reaction Cell, or QRC, develop and deploy material solutions to Soldiers' requirements, they look to Tank Armament Command's Integrated Logistics Support Center, or ILSC, Soldier, Product Support Integration Directorate to provide the foundations of logistical and sustainment support.

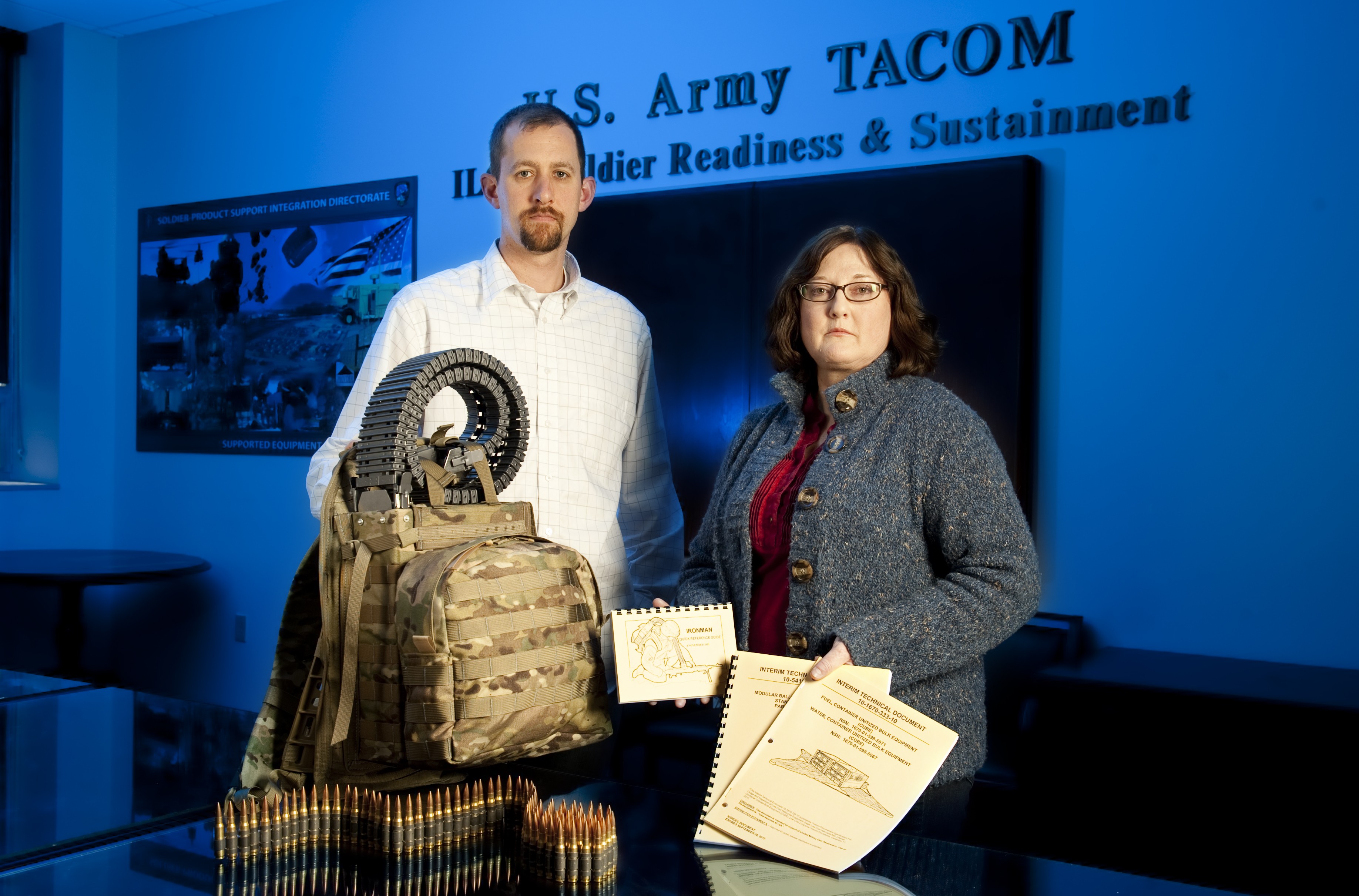

The ILSC creates Interim Technical Documents, known as ITDs, which allow for Soldiers in the field to learn how to properly use and assemble various items, identify and acquire spare and repair parts, and provide feedback to the NSRDEC QRC to improve the design and performance.

"Fortunately, the QRC Project leads have thought about the sustainment piece of their projects," said Samuel Pitts, ILSC Integrated Logistics Support manager. "Not only have they provided an outstanding technical solution, but also something that is supportable in the field."

By bringing logistics into the design and early assessment process, these ITDs can be overpacked, meaning they are physically sent to the field with the system. The ITDs provide Soldiers with documentation necessary for operations, care, and maintenance of these developmental items.

"It's exciting to be part of these efforts, to see the CUBE (Container Unitized Bulk Equipment), Ironman, and MBPS SA (Modular Ballistic Protection System) as solutions for Soldiers' concepts and needs," said Rachel Grady, ILSC Technical Publications writer.

The Container Unitized Bulk Equipment is a transportable container that can hold fuel, water, and other items; the CUBE can be airdropped or sling loaded via helicopter and is a low-cost limited reuse system. The Modular Ballistic Protection System is a stand-alone armor panel system that is quickly erectable and is integrated around the perimeter of a weapons system or an already deployed shelter for protection from small-arms fire and fragmentation when more heavy-duty systems are not available.

Soldiers' most vulnerable time is when they arrive and they need to set up the MBPS SA; this is just one example of the ITDs' importance.

"Because they [the Soldiers] have nothing to protect them, an ITD will help them figure out the easiest and quickest way to set up the MBPS," Grady said.

All three of these systems are currently in theater, after mere months of conscientious development and planning among multiple directorates. The Army is currently conducting Forward Operations Assessments through Test and Evaluation Command for these systems. The assessments will be done by August 2012.

Soldiers are able to assess value and evaluate the ITD against the equipment they receive. To improve the designing process, all the information is going to feed back to the NSRDEC QRC.

"We want to know if steps need to be added or changed," Grady said. "We also want to know if the illustrations accurately depict the procedures. Even though we validate the ITD, if you're the person who uses it on a daily basis, you know what works and what doesn't work. It is invaluable to have the Soldiers' input."

ITDs can be produced within a few months, while official Army authenticated technical manuals, known as TMs, can take anywhere from one to three years to produce. One of the most important features of an ITD or TM are the national stock numbers, or NSNs, associated with the parts. These are pertinent for Soldiers because it allows them to order parts or look at characteristics of items.

Establishing NSNs can sometimes be a lengthy process, but the ILSC establishes these numbers so that Soldiers may go straight to their repair parts and special tools list, known as an RPSTL, and get the information they need to order a replacement or repair part.

"We are taking what we do, developing the logistics footprint for Army products, which generally takes 18 to 24 months, and adapting that process appropriately to meet the short timelines that the NSRDEC QRC operates under," Pitts said. "These are not official TMs because these are not official programs of record yet, but we basically establish procedures on how to put together and use systems, and we provide a conduit into the standard Army supply system, allowing them to requisition spare and repair parts."

By coordinating with different experts including engineers, photographers, ILS managers, equipment specialists, among others, ITDs can be created in-house in an efficient manner that meets the schedule the NSRDEC QRC asks for in order to provide the most up-to-date ITD.

"The QRC is taking requirements from the field and matching it up with the advanced engineering they see happening at the NSRDEC," Pitts said. "It's great that they have the forethought to pull the logistic element in to create these baselines that are going to give the Soldiers basic information they need to set up, operate and repair these systems."

Getting Soldiers the items and parts they need in the shortest amount of time possible, as well as providing proper instructions and tools for them to support these items in the future, are just a few ways TACOM's ILSC Soldier PSID has been able to team up with the NSRDEC QRC and other in-house R&D directorates to provide and generate feedback for and from our Soldiers, respectively.

Related Links:

Natick Soldier Development and Engineering Center

'Ironman' a game-changer on battlefield

Social Sharing