ADELPHI, Md. (Jan. 15, 2015) -- Just as the human immune system deploys antibodies to destroy bacteria that have infiltrated the body to cause harm, Army scientists may deploy biosensors to detect harmful microorganisms.

Scientists who specialize in biosensing at the U.S. Army Research Laboratory at Adelphi, Maryland, want to mimic the behavior of antibodies by using alternative, artificial peptide material to detect harmful particles that could threaten Soldiers.

Peptides are the building blocks of the natural world, said Dr. Dimitra Stratis-Cullum, who started the program at the laboratory about 10 years ago.

Waves of antibodies are at work in the human body looking for tiny single-celled organisms called bacteria. These antibodies can also sense viruses, which are even smaller than bacteria.

"Biosensing technology is not currently capable of widespread use outside of a laboratory environment due to significant limitations in bioreceptor function and production, as well as in the overall size, weight and cost of the sensing platform," Stratis-Cullum said. "As technology continues to advance, biosensors could truly become ubiquitous, employing social media and personal electronic devices for mundane yet powerful capabilities."

In the near future, point-of-care diagnostics could save millions of lives and revolutionize the healthcare industry worldwide, she said.

"I would like to see the Army's capacity for biosensing expanded," Stratis-Cullum said.

For years, scientists like Stratis-Cullum have grappled with the question: "How do you take the power of antibodies and translate that to a synthetic, robust stable solution without compromising performance?"

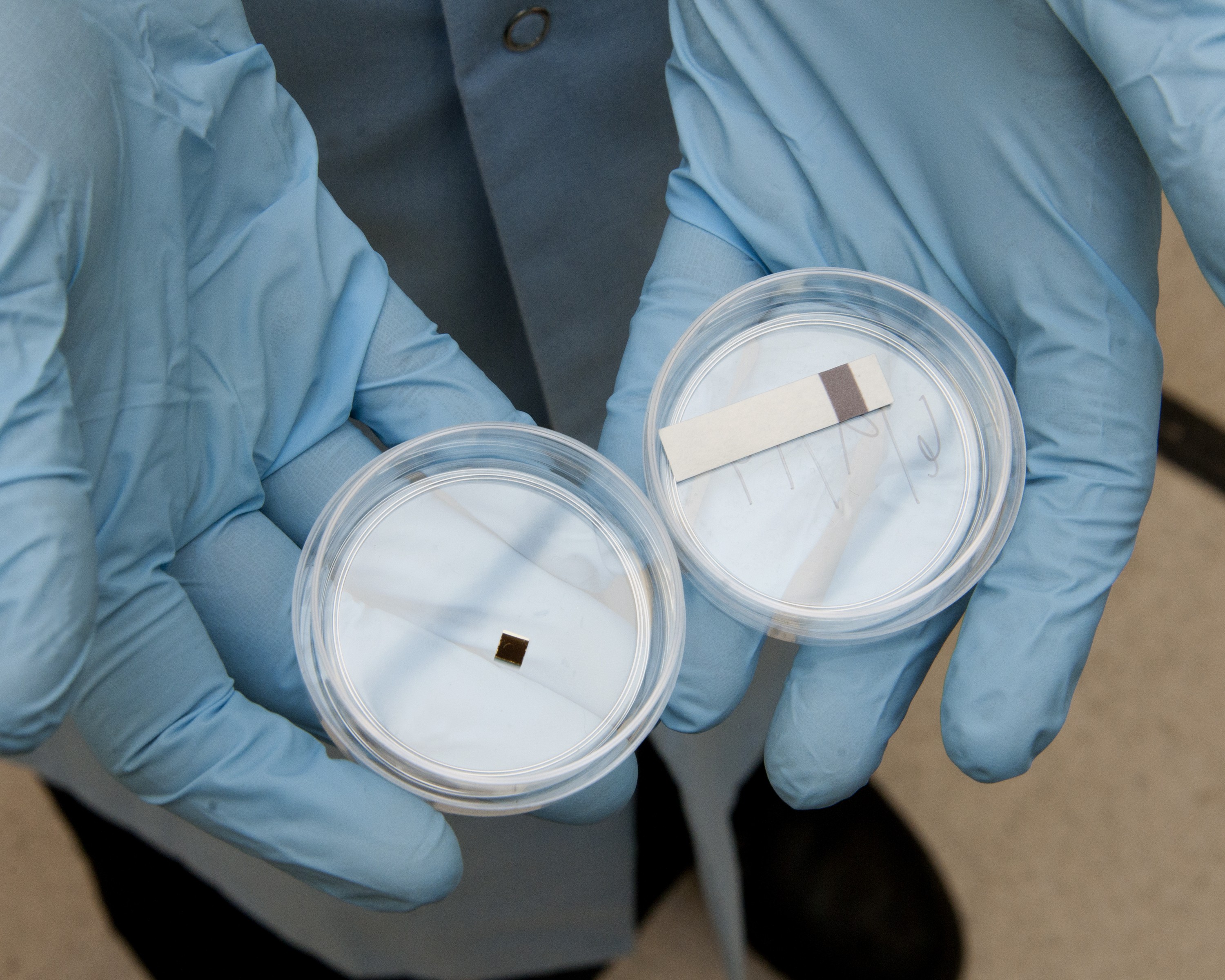

Mikella Farrell, an ARL research chemist who typically works with chemicals, wants to extend to biological targets. She said scientists can identify biological targets, but are still seeking to do so outside of a laboratory environment. Army researchers have a handheld device that uses Raman spectroscopy, but it is very limited, especially in shelf-life and storage, she said.

Raman spectroscopy is used to understand the make-up of materials, down to the chemical bonds. A sample is illuminated using a single colour of light and the way the light interacts with the sample tells us information about it.

Farrell explores surface-enhanced Raman scattering as a way to more sensitively detect a host of hazardous material from explosive residues, to much less likely detected substances, like biological hazards, she said.

If the laboratory could develop a prototype platform capable of detecting threats, then Farrell's work may rely on the material-binding peptides for selective capture of harmful chemicals from a complex mixture.

Another challenge is devising the right tools to controllably, reproducibly discover materials, while also meeting Army requirements.

There are many alternatives to antibodies under investigation by the scientific community, Stratis-Cullum said.

"The Army needs an alternative that is first of all, thermostable, or maintains its properties under extreme temperatures; and second of all is able to perform well under austere battlefield conditions," she said.

Other alternatives have one or the other but not both thermostability and binding performance.

During DARPA Antibody Technology Program testing in 2012, the program showed an increased antibody affinity by a factor of 400, which opened the door to vastly more sensitive, multiplexed biosensors. Temperature stability was increased to 70 degrees Celsius for 48 hours, a dramatic improvement from the previous limit of five to 10 minutes, said Mildred Donlon, DARPA program manager.

"By removing temperature stability as a limiting factor, troops will now be able to carry sensors with them without worrying about refrigeration or wondering if the sensor will return an accurate reading," she said. "The new stability also means antibodies can be attached to new materials to potentially make more practical sensors."

In the most recent round of testing, the ARL material showed no loss of performance after one week at 70 degrees Celsius, and retention of the majority of performance after an hour at 90 degrees Celsius, which is an improvement from two years ago.

"While exciting, it is one thing to say we could get a device to work once, but we need the technology to yield the same results every time," Stratis-Cullum said.

Troops ultimately need something durable and dependable that functions like a library, detecting any number of hazardous combinations, not just the more obvious threats, she said.

Although ARL researchers have made great progress in the past 10 years, there is more work to be done before there a viable prototype could be used in the larger platform, Stratis-Cullum said.

The next step is to determine the peptide's sensitivity limits and demonstrate results on sensing platforms.

ARL partners with Edgewood Chemical Biological Center at Aberdeen Proving Ground, Maryland, to improve simple handheld biosensors Soldiers use in the field, among other sensing platforms.

ECBC supports the foundational work at ARL by testing and evaluating the new materials.

"We have partnered with ECBC very early in the process to continuously benchmark along with the current standard," Stratis-Cullum said.

The biotechnology team hopes to further the Army's ability to develop the next generation of synthetic biology tools, and discover and study biointerfaces, she said.

"We are working to enable autonomous organization and bottom-up assembly through fundamental research," she said. "The goal to understand and control biointerfaces will be key to unlocking a whole new generation of biotechnologies that exploit the programmable nature of living biological materials. It is an honor to be at the forefront of harnessing the power of biosciences for beyond next generation smart sensor technology."

----

This article appears in the January/February 2015 issue of Army Technology Magazine, which focuses on sensors research. The magazine is available as an electronic download, or print publication. The magazine is an authorized, unofficial publication published under Army Regulation 360-1, for all members of the Department of Defense and the general public.

The Army Research Laboratory is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness--technology, acquisition support, materiel development, logistics power projection and sustainment--to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Related Documents:

<b>Army Technology Magazine</b> [PDF]

Social Sharing