WATERVLIET ARSENAL, N.Y. -- During the arsenal's more than 200-year history it has adapted to countless changes to its production lines having gone from packing flannel ammunition cartridges during the War of 1812 to manufacturing mortar systems for today's troops who serve in Afghanistan.

But the production change at Watervliet this month was unlike anything the arsenal had experienced before and it has a Canadian company to thank for it.

Yap Films, an independent film company out of Toronto, set up cameras and lights throughout the historic arsenal August 13-20 to capture footage for a documentary film titled, "Troop Factory."

James Ellis, a senior researcher at Yap Films, said that his production company selected the arsenal site due to its status as the premier manufacturer of tank, artillery, and mortar tubes in the world.

Ellis said the production will take the viewer into the hidden world of military factories all over the world, where raw materials become finished products. The 14-episode series will reveal how these things are made right before the viewer's eyes.

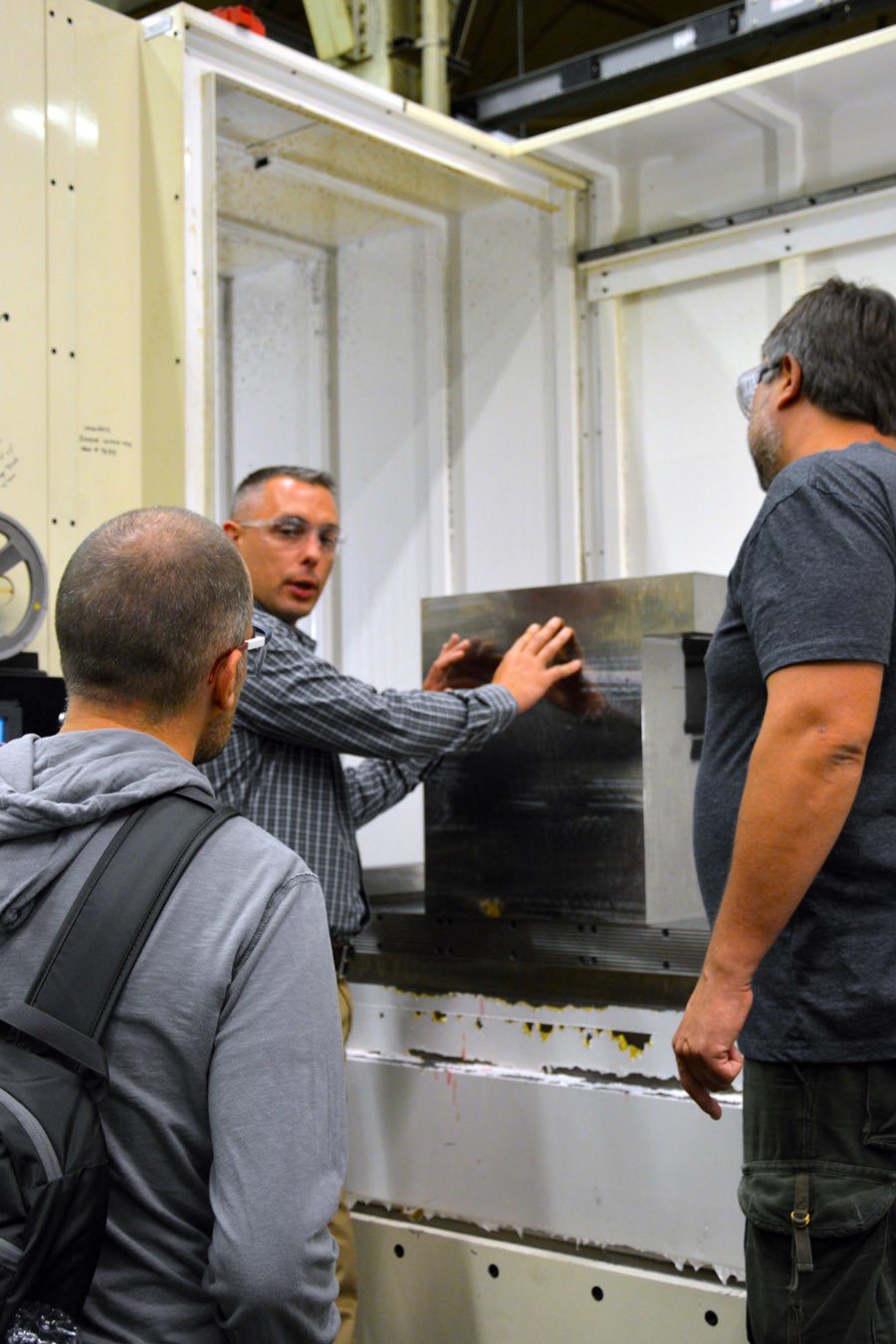

During the course of filming, 35 employees, from packaging to machining, were highlighted in various levels of the production process.

With the war in Iraq having ended and the bulk of U.S. troops out of Afghanistan, this production could not come at a better time, said Col. Lee H. Schiller Jr., the arsenal commander.

"We have always believed it is important to tell the Army story, as well as our own story," Schiller said. "But in an era of declining defense budgets, telling our story has become increasingly more important if we are to ensure our long-term viability as an Army-owned and operated arsenal."

"By hosting Yap Films for five days during a very busy manufacturing cycle, we have made an investment in our future" Schiller added. "Through their work, Yap Films will extend the arsenal's messaging into international markets where foreign military sales may help us fill the gap caused by a declining U.S. workload requirement."

General Foreman Leon Rosko, who spent several days with the film crew, echoed the commander's words, or at least the intent of the commander's words, by saying that there was value to hosting Yap Films.

"Anytime we can have a dedicated film crew come in to help us tell the arsenal story is a significant event and one that we will fully support," Rosko said. "When most Soldiers do not understand the detail and effort that goes into the making of their weapon systems, anything we can do to better tell that story is of tremendous value."

Because the film crew captured everything from forging to assembly to packaging, some of the arsenal's apprentices sometimes became unwittingly action shots during the filming. It is one thing for a machinist with nearly 40 years of experience to explain in detail the machining operation that they are performing, but challenging an apprentice who has just completed their first two years of a four-year program didn't matter to the film crew. The film crew gave the apprentices just as much respect as they gave to the senior machinists because at the end of the day, the apprentices were the experts on the machining operation that they were performing.

Apprentice Colin McCarthy said of his experience with the Yap Film crew, "I think having a film crew here was extremely valuable so that people outside of New York's Capital District would have an understanding of what we do here. The crew was great to work with and they asked detailed questions. But what was nice to see, however, was that the film crew seemed genuinely interested in learning about our capabilities and our workforce despite having visited several manufacturing centers before filming here."

Yap Film Director Michael Cammidge said as his team was wrapping up the shooting that he was impressed with the enormous amount of process and quality that goes into each part manufactured here.

"I don't believe that Soldiers fully understand the amount of detail in regards to the tight machining tolerances that often are measured in the tens of thousandths of an inch or about the high number of quality control checks that are performed after every major manufacturing operation," Cammidge said. "And so, it is our job to tell that story and to do so in a crafted, cinematography effort."

Of all the hundreds of independent operations the film crew had access to, the number one highlight to the crew was not the rotary forge or the bending of a howitzer tube, it was the people, Cammidge said.

"We were truly impressed by a workforce who are highly motivated, very professional, enormously talented, and who truly know the importance of what they do for Soldiers," Cammidge said.

As the plan is now, the arsenal will have three-five minute film clips that will follow three major product lines through receipt of raw material to the finished product: 105mm howitzer tube; 81mm mortar systems; and a 120mm tank breech ring.

The series will run in 2015 on Discovery International and the History Channel Canada and United Kingdom TV.

______________

Yap Films

-Yap films is a highly respected independent production company specializing in producing factual specials and series on a wide range of subject matter for broadcasters in Canada, the United States, the United Kingdom, and beyond. We've built our reputation through passion and integrity and embody the highest standards of professionalism.

-In recent years, yap has produced for or coproduced with History Television, History Channel US, Yesterday, Discovery Channel, the BBC, National Geographic, the Smithsonian Channel, France 5, and CNBC, among others.

Watervliet Arsenal

-The Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest, continuously operating arsenal in the United States, having begun operations during the War of 1812. It celebrated its 200th anniversary in July 2013.

-Today's arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $90 million.

Related Links:

Arsenal Story:Battles are won by logistics, so are arsenal production schedules

Social Sharing