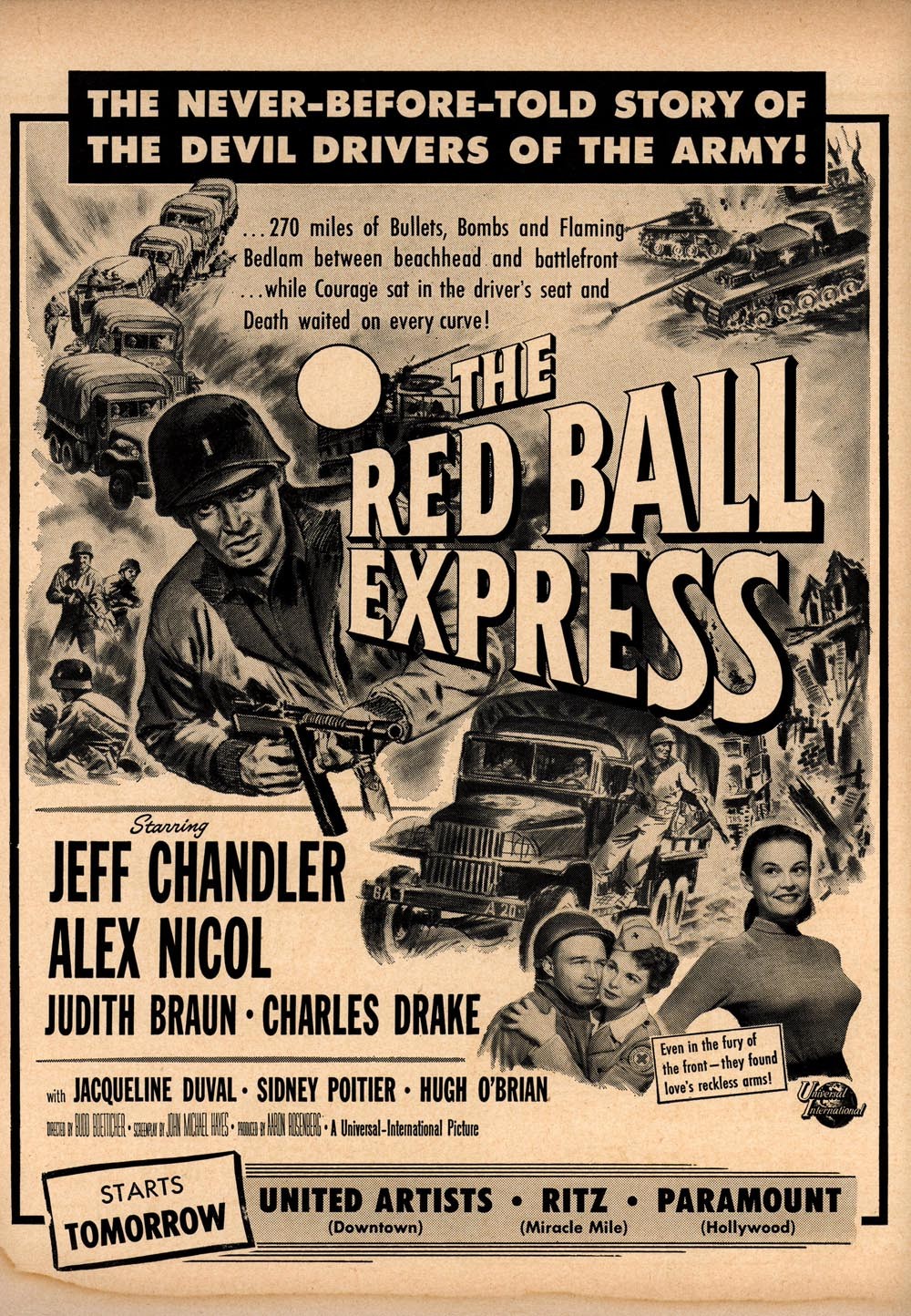

WATERVLIET ARSENAL, N.Y. (Aug. 6, 2014) -- Third Army's Red Ball Express Operation will celebrate its 70th anniversary on August 25, which was a storied logistical achievement having moved more than 412,000 tons of supplies from the shores of Normandy to forward deployed combat troops in the First and Third Armies.

The operation was created on Aug. 21, 1944, with the first trucks rolling four days later. On an average day, nearly 900 fully loaded vehicles moved more than five tons of gas, oil, ammunition, spare parts, and food along a treacherous 400-mile route. Nearly 75 percent of the drivers were young African-American Soldiers who at their peak delivered 12,342 tons a day to an American Army that had fought its way off the beaches and was in hot pursuit of the German army.

Of this historical feat, Gen. Dwight D. Eisenhower said in a letter to the Red Ball Express team:

"In any war, there are two tremendous tasks. That of the combat troops is to fight the enemy. That of the supply troops is to furnish all the material to insure victory. The faster and farther the combat troops advance against the foe, the greater becomes the battle of supply … So the Red Ball Line must continue the battle it is waging so well, with the knowledge that each truckload which goes through to the combat forces cannot help but bring victory closer."

The spirit of Eisenhower's thoughts regarding just how important logistics are to the success of the war fighter has also been the same line of thought and spirit at the historic Watervliet Arsenal. From the Battle of New Orleans to the battle of Kandahar Valley, arsenal products have helped hundreds of thousands of U.S. troops to come home safe from battle.

And in a much smaller scale, the internal logistics operations at Watervliet also create an environment that facilitates the successful manufacturing of tank and artillery cannons, as well as that of 60mm, 81mm, and 120mm mortar systems, for U.S. and foreign militaries.

The arsenal motor pool team of three is responsible for more than 200 line items of equipment that require dispatching, licensing, refueling, maintenance and light repair. The scope of this task ranges from maintaining an 80-ton crane for the manufacturing center to repairing a lawn mower for public works.

Mary LaHait, Dan Belk, and Michael Hockenberry have a magical chemistry between them that allows them to face what some would believe is a daily insurmountable task with a sense of humor and a strong can-do attitude.

LaHait, as the transportation assistant, is the office ramrod who manages the dispatching, licensing, work orders, and anything else that it takes to track and coordinate maintenance and repair of the equipment.

Belk and Hockenberry, both militaryVeterans, are the wrench turners who on any given day have a large motor pool filled with equipment ready for maintenance, troubleshooting, or for minor repair, such as replacing hydraulic pumps and alternators.

"We come in each day with a plan thought out and tasks prioritized," Belk said. "But just like in war no plan survives the first contact with the enemy."

The enemy in Belk's case is the shear scope of well-used equipment that can be as fickle to plan maintenance for as the seasons in which they operate.

According to Hockenberry, if it wasn't for the fact that 43 vehicles belong to the General Services Administration fleet, there would be no way for the small motor pool operation to stay on top of critical maintenance.

GSA, through its leasing program, frees the arsenal from having to purchase vehicles, such as four-door sedans and five-ton dump trucks, or provide maintenance and repair for the vehicles. If a GSA vehicle is ready for a scheduled maintenance, such as an oil change, all the arsenal has to do is take the vehicle to a local car dealership that is approved by GSA.

Nevertheless, Belk added that the arsenal's GSA fleet still requires a significant amount of his time.

"If all I had to do every day was to repair equipment and vehicles, my day wouldn't be too bad," Belk said. "But even with GSA vehicles I still have to diagnose the maintenance problem, coordinate with a vendor, and then get the vehicle to the vendor for repair."

Belk said that nearly half of his time each day is not repairing or conducting maintenance, but performing administrative work that is required for each piece of equipment.

In their spare time, LaHait, Belk, and Hockenberry are also part of the arsenal's snow removal team. When there is a shortage of drivers, Belk and Hockenberry also drive gun trucks.

While LaHait, Belk, and Hockenberry struggle to keep their magical relationship, as well as arsenal priorities, in tack, their efforts are not unappreciated.

"Each day they make sure that the Arsenal keeps moving, literally," said Greg Stopera, the arsenal's chief of the Logistics Management Division. "They fight an unwinnable battle against the chaotic nature of equipment failure and conflicting priorities, and do so with an unwavering sense of duty to the arsenal's mission and commitment to their customers."

So, how do they keep their motivation up in an environment described by their boss as unwinnable?

"We have become, just like the old Army tagline, an army of one," LaHait said.

The importance of those who perform logistics cannot be overstated. From the days of Alexander the Great to General Patton's Red Ball Express to the motor pool operation at Watervliet, logisticians' place in the annuals of history books is well documented.

After all, there would not be 200 years of arsenal history if it wasn't for the eight generations of logistical workers, such as LaHait, Belk, and Hockenberry, who have through the years quietly accepted and accomplished all missions even when it may have seemed that their challenges were insurmountable.

-----

The Watervliet Arsenal is an Army-owned-and-operated manufacturing facility and is the oldest, continuously operating arsenal in the United States, having begun operations during the War of 1812. It celebrated its 200th anniversary in July 2013.

Today's arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $90 million.

Related Links:

Arsenal Story: 'Right' defense contracts needed to support critical skill retention at Watervliet

Watervliet Arsenal Flickr Page

Watervliet Arsenal Slideshare Page

Watervliet Arsenal YouTube Page

Social Sharing