24-815_Saving Soldiers Time (Jan 24) (Public).pdf

INTRODUCTION

Think of it like a massive spring-cleaning effort, with a bit of help. As you might imagine, a 248-year-old organization can acquire and consume a lot of stuff, particularly an organization with nearly a million full-time and part-time members. The United States Army is such an organization. It is no surprise that while undergoing one of its largest transformations since the incorporation of the AirLand Battle conceptual framework in the early 1980s, this latest makeover would involve tremendous amounts of materiel and vehicle turnover.

Developed as a concept in 2018 and implemented in 2022, the Regionally Aligned Readiness and Modernization Model (ReARMM) is a framework that enables the Army to remain competitive by establishing persistent associations with specific missions and theaters, fostering predictable environments that enable modernization and maintain organizational readiness. Modernization Displacement and Repair Sites (MDRSs) enable the Army’s strategic divestment of legacy equipment, so its units are better prepared to receive new, modernized materiel. Put simply, MDRSs save Soldiers’ time by allowing them to get rid of old, broken materiel they no longer need and use their time to prepare for the new, modernized equipment they will receive as part of the ReARMM process.

Beginning as a singular proof of purpose concept just three years ago, there were as many as 14 MDRS facilities across the contiguous United States, Hawaii, and Alaska, enabling predictable, efficient modernization environments for Army units. MDRSs serve as convenient one-stop shops for unit supply and maintenance personnel by receiving, accounting for, and repairing (if necessary) Army-designated excess equipment for transfer or turn-in.

This paper informs commanders and staffs on the creation and evolution of operating procedures of MDRSs. This includes discussion of the disposition process and how disposition instructions guide preparation and execution of units’ interactions with an MDRS. Most importantly, this paper discusses best practices and issues units can use to plan for and ease their turn-in processes.

WHY THE ARMY CREATED MODERNIZATION DISPLACEMENT AND REPAIR SITES

The ReARMM framework empowers the Army to transform into a multidomain-capable force as its focus transitions from counterinsurgency to great power competition and large-scale combat operations. Former Army Chief of Staff, General James C. McConville, noted in a 2019 message to the Army, “We must transform all linear industrial age processes to be more effective, protect our resources, and make better decisions. We must be the Army of tomorrow, today.”

Given this new emphasis, today’s Army has too much obsolete equipment not optimized for its future missions and threats. The Army needs to modernize but must first shed unnecessary equipment; repair and upgrade what will be kept; and field newer, capable equipment across formations. This must be done quickly and having a unified, consistent approach increases the velocity for which these processes can happen.

Under the MDRS program, the Headquarters, Department of the Army (HQDA), directed that equipment divestiture would involve planned, systematic operations among all major commands and provided guidance to support and synchronize its planning and execution across the force. HQDA directed Army Materiel Command (AMC) to establish the first MDRS-Cavazos at Fort Cavazos, Texas, as a proof of purpose program in November 2020.

The MDRS program mirrored 1st Cavalry Division’s Operation Pegasus Harvest, which the division implemented in mid-2020 to provide relief for its unit’s excess equipment and prepare for forthcoming new, modernized equipment. The proof of purpose was a resounding success, and HQDA directed AMC to establish 13 additional MDRSs 4 months later to service active component units across the continental U.S., Alaska, and Hawaii. MDRS can support units other than active- duty on a case-by-case basis depending on proximity, mission set, and other factors with approval from AMC. Though Army Reserve and Army National Guard units cannot use MDRSs for any of their unneeded equipment because of funding constraints and current facility backlogs, AMC maintains an open dialogue with them regarding opportunities and in trying to establish similar capabilities within their own formations.

MODERNIZATION DISPLACEMENT AND REPAIR SITES 101

MDRSs help Army units prepare for their ReARMM modernization phases by unburdening them of excess materiel and expediting its redistribution. More specifically, MDRSs provide immediate property accountability relief, supported unit-funded maintenance, and transportation coordination of unit vehicles and equipment so unit members can avoid spending time on materiel they are about to lose and focus on the receipt of new, modernized equipment.

The 14 MDRSs have three primary functions:

- Receive and possibly repair excess materiel and equipment from Army units.

- Facilitate lateral transfers (LTs) of items between installations or Army commands (ACOMs).

- Deliver materiel and equipment that is no longer needed to Army depots or Defense Logistics Agency – Disposition Services (DLA-DS) for repair or future disposition.

Of course, the Army always had and still has traditional, established procedures and facilities to accomplish these tasks, but MDRSs streamline the process and serve as one-stop shops for turn- in (also referred to as induction) and property book management, thus increasing velocity and capacity.

Understandably, the breadth of Army equipment inventory scrutiny is immense – current fleets of vehicles and equipment need evaluation to determine which fleets or platforms should be retained, repaired, or divested. The Department of the Army makes these determinations with units chosen based on their theater alignments; expected adversaries; component, unit, and equipment availability; and a multitude of other factors. With respect to MDRSs, much of it comes down to a matter of space - before units can accept new equipment, they must get rid of their current sets.

As beneficial and user-friendly as MDRSs are, there are some tasks they do not perform. As this article will later discuss, they do not process equipment designated for on-post LTs for losing and gaining units within the same ACOM. These items should transfer between units per normal Army Regulation (AR) 750-1, Army Materiel Maintenance Policy, equipment transfer policy. MDRSs are not dumping grounds for units’ rapid property book optimization. The excess equipment they receive and process is designated for transfer or turn-in by units’ higher ACOM headquarters or AMC.

With respect to MDRS operations, losing units are Army units that have excess equipment they will surrender to MDRS facilities for subsequent disposition based on proposed sourcing decisions (PSDs) from their ACOM headquarters or Army Sustainment Command (ASC). Oftentimes, these items are broken or damaged and MDRSs do not repair them based on unit request. MDRSs repair only items designated for LT or turn-in to Army depot or DLA-DS and losing units must pay for any maintenance on equipment they turn in. Finally, MDRSs do not accept Class II clothing and equipment or Class IX repair parts and components. Units must follow standard Army supply procedures to divest of these items.

STRUCTURE AND REPORTING CHAIN

ASC, 1 of 10 AMC subordinate commands, operates MDRSs through its individual installation Logistics Readiness Centers (LRCs) and Army Field Support Brigades (AFSBs). LRCs integrate AMC capabilities and enable single customer touch point for supply, maintenance, and transportation services across Army installations worldwide. AFSBs and their subordinate Army Field Support Battalions (AFSBns) provide access to AMC’s wide-ranging strategic-level materiel support at home station and forward locations.

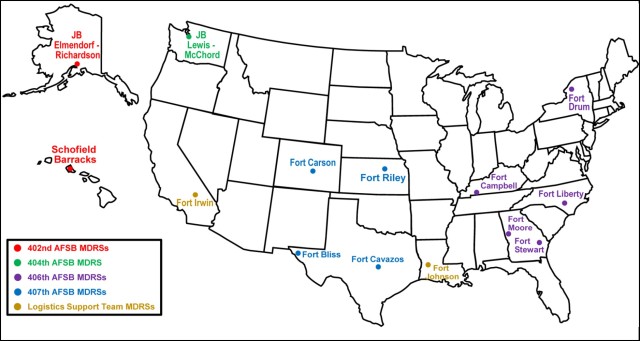

As Figure 2 shows, four of the ASC’s eight assigned AFSBs have MDRS mission responsibilities: the 402nd, 404th, 406th, and 407th AFSBs. Separate logistics support teams at Forts Irwin and Johnson operate their installation MDRSs because there are no AFSBns at those locations. As beneficial as MDRSs are to the Army thus far, ASC is poised to close the Forts Irwin, Johnson, and Moore sites in late 2023 because of resource constraints and decreased usage rates over the past three years. Given these installations are not as populated as many others with major Forces Command (FORSCOM) units; such as corps and division headquarters, brigade combat teams, and other support and functional commands; this outcome is foreseeable. Fortunately, the remaining 11 MDRS facilities are close and can accept vehicles and equipment from the MDRSs that close.

Those AFSBns operating MDRSs generally have separate sections with the personnel, equipment, and facilities necessary to perform the MDRS mission requirements. MDRS facilities oftentimes occupy battalion-sized motor pools to allow availability for adequate vehicle parking space, internal building storage space, and provide for appropriate physical security measures to safeguard equipment and materiel onsite.

KEY TASKS

At the strategic level, the Department of the Army directed 12 major tasks for AMC in 2020 with respect to the MDRS mission, some of the more notable ones that have endured through to today include:

- Establish and maintain responsibility for MDRSs.

- Provide equipment transfer guidance through PSD processes.

- Provide supply accountability relief through LT to MDRSs.

- Maintain supply discipline and ensure minimal health, hazardous materials, safety, and security requirements are met.

- Ensure equipment is transportation-ready.

- Arrange freight shipments to gaining organizations or depots.

- Establish physical holding yards and take physical possession of all equipment transferred to MDRSs.

- Prepare all required substantiating documentation for gaining organizations, depots, or DLA-DS.

- Develop MDRS business rules and establish reimbursable funding processes to execute reimbursable maintenance and supply functions in conjunction with FORSCOM.

Currently supported unit responsibilities for MDRS equipment processing include: scheduling and completing all appointments and inventories with local MDRSs; completing post goods issues (PGIs) in Global Combat Support System – Army (GCSS-A) to MDRSs before equipment induction; providing all required property and maintenance-associated paperwork; closing all previous equipment work orders; delivering items in transportable conditions; and funding any requested maintenance support.

MDRS and supported unit responsibilities vary based on PSD’s disposition instructions. As discussed, the MDRS program enables efficient LT or turn-in to other units either on or off- installation or to Army depots or DLA-DS. ACOM internal LTs (on installation) is another situation in which units identify excess equipment that another unit in the same ACOM requires. MDRSs will not accept and process these items – they are handled within a respective ACOM’s disposition instruction. The MDRS-eligible actions, which the Army identifies as “buckets,” are labeled as follows and described below:

- ACOM internal LT (off installation)

- ACOM to ACOM LT

- ACOM to depot turn-in

- ACOM to DLA-DS turn-in

Excess Equipment Displacement

Figure 4 provides a flowchart for excess equipment displacement. The chart begins in the upper left in the dark grey box, indicating a unit has current or anticipated excess equipment based on forthcoming modernization fieldings. The decisions shown along the top of the flowchart demonstrate a unit’s ACOM, determining if equipment is laterally transferred elsewhere within the same ACOM, laterally transferred to another ACOM, or turned in to Army depot or DLA-DS. The figure displays the buckets as orange trapezoids, losing unit and MDRS activities in yellow boxes, and final equipment disposition as blue ovals.

If equipment is no longer needed by a unit but needed by another unit within the same ACOM, the ACOM issues a direct LT order. Unit-to-unit LTs on the same installation (indicated as “ACOM Internal (On Installation)” on the left side of the flowchart) will not involve MDRSs. ACOMs transferring equipment within their command but on another installation (indicated as “ACOM Internal (Off Installation)” on the center left of the flowchart) will issue a PSD and the equipment will follow the Bucket 1 path. MDRSs will accept, process, and coordinate shipment to its destination and gaining activity with maintenance performed with a corresponding work breakdown structure (WBS) as required.

Equipment that is not excess to the Army or on its master divestiture list (MDL) and is required by another ACOM (indicated as “ACOM to ACOM LT”) is laterally transferred on the Bucket 2 path in the center of the flowchart.

Equipment that is excess to the Army or on the MDL is turned in either to Army depot (Bucket 3) for storage or DLA-DS (Bucket 4) for disposal or transfer to other domestic or foreign governments, agencies, or commercial use. The “Depot or DLA-DS Turn-in” procedures follow along the far right of the flowchart.

Regardless of equipment’s end point, MDRS staffs work diligently and place continual emphasis on accepting and moving equipment forward to keep pace with ReARMM modernization timelines and unit phases.21 HQDA’s MDRS External standard operating procedure (SOP) directs specific roles and responsibilities regarding each action and are described below.

Bucket 1: ACOM Internal Off Installation LT

Modernization Displacement and Repair Sites accept, process, and coordinate ACOM internal off installation LTs as directed by PSD disposition instructions. LT items will meet AR 750-1, Army Materiel Maintenance Policy, paragraph 4-9, equipment transfer and turn-in standards. MDRSs repair equipment to meet Army transfer standards if supported units provide funding for the corresponding WBS. MDRSs perform joint technical inspections (TIs) of equipment with units that do not have funded maintenance support agreements before providing property accountability relief.

Losing units of equipment designated for MDRS-eligible LTs coordinate induction appointments with their local MDRSs. Pre-induction meetings between units and MDRSs enable confirmation of PSDs and required paperwork to ensure accurate equipment identification information and maintenance data. Supported units close all previous equipment work orders and their supply representatives verify the inducted equipment is PGI in GCSS-A to the MDRS property book officer (PBO). GCCS-A data is transferred from losing units to MDRSs and subsequently to end gaining units as applicable.

MDRSs only accept generally clean rolling stock vehicles with no leaks; front and back shackles; tracks present for tracked vehicles; and removed communication equipment, including antenna mounts and cables.

MDRSs and losing units conduct a joint induction inventory to validate equipment models and serial numbers against all disposition documents. Joint technical inspectors then validate equipment condition and verify everything meets AR 750-1, Army Materiel Maintenance Policy, paragraph 4-9, equipment transfer and turn-in standards.

Required induction paperwork includes one copy of the associated PSD; two copies of DA Form 3161 (Request for Issue or Turn-in); one copy of DA Form 1687 (Notice of Delegation of Authority – Receipt for Supplies); one copy of DA Form 5988-E or DA Form 2404 (Equipment Inspection and Maintenance Worksheet). If no DA Form 5988-E exists, the MDRS will generate the form.

The final step for either of the LT processes is completing property book accountability. MDRS PBOs formally accept and sign turn-in receipts, provide copies to losing units for their records, and then post receipt of the equipment in GCSS-A. Both losing unit and MDRS PBOs update lead materiel integrator-decision support tool with their respective document numbers to close the PSD.

Bucket 2: ACOM to ACOM LT

Lateral transfers of equipment between different ACOMs follows the same process as Bucket 1, a transfer within the same ACOM, but the losing and gaining units are on different installations.

Bucket 3: ACOM to Depot Turn-in

Units divesting of Army depot-designated equipment turn over these items generally “as is,” “as is, complete with basic issue items/component of end items,” or “in accordance with AR 750-1, paragraph 4-8, equipment transfer and turn-in standard,” meaning they give up the equipment in its current condition with no maintenance required. Rolling stock vehicle requirements are the same as Buckets 1 and 2.

Turn-in responsibilities and procedures are the same as well, except no joint TI is required. Losing units must note accurate condition codes for all equipment. Any medical devices, sets, kits, or outfits handed over to MDRSs must be clean and in their original or suitable cases or coverings to be ready for transport.

Bucket 4: ACOM to DLA-DS Turn-In

Units divesting of equipment designated for DLA-DS turn-in deliver these items “as-is” and MDRSs prepare all required documentation, make necessary appointments, and transport the equipment to receiving sections designated by DLA-DS. DLA-DS disposes excess Department of Defense (DoD) personal property, foreign excess personal property, scrap, hazardous waste, and property requiring demilitarization.

Rolling stock vehicle requirements are the same as Buckets 1 through 3, except tracks are not required for tracked vehicles (MDRSs accept these vehicles “as-is”). Bulk fuel tankers also do not require purging. Like equipment destined for depot turn-in, joint TIs are not required, but medical devices, sets, kits, or outfits must be clean and in their original or suitable cases or coverings to be ready for transport.

EQUIPMENT TRANSFER AND TURN-IN STANDARDS

Property transfers always involve a corresponding paper trail and working with MDRSs offer no exception – corresponding property book and maintenance service paperwork will accompany MDRS inductions. It is not an automatic process enabling losing units to get rid of their vehicles and equipment as is, with little to no regard for mission capability. As convenient and efficient as MDRSs are, these considerations cause differences of opinion and undeniable frustration for both Soldiers and MDRS personnel, but that is the purpose for this article – to discuss lessons of the MDRS turn-in process and make it a smoother process for all.

MDRS equipment transfer and turn-in policy is determined by AR 750-1, Army Materiel Maintenance Policy. Losing units prepare a jointly approved LT document to coordinate transfers between ACOMs, Army Service Component Commands (ASCCs), and Direct Reporting Units (DRUs). Applicable national inventory control points approve transfers to other DoD military departments or other government agencies in accordance with AR 710-1. Equipment transferred between ACOMs, ASCCs, and DRUs, including Army Reserve and Army National Guard, transferred into the Army pre-positioned stock (APS), prepared for storage below the national level, and other specified stocks must meet the following requirements: Technical Manual (TM) 10 series and 20 series maintenance standards or appropriate technical data plans; current scheduled services as of the losing organization’s shipment date; preventive maintenance checks and services (PMCS) and preventive maintenance inspections complete with accompanying records; and other specific APS, Army war stocks, depot overhaul, and winterization requirements.

Army equipment meets TM 10 and 20 series maintenance standards when all the following conditions are met:

- The equipment is fully mission capable (a materiel condition indicating systems and equipment are safe and have all mission-essential sub-systems installed and operating as designated by applicable AR).

- Faults are identified following applicable TM 10 and 20 series PMCS prescribed intervals.

- Repairs and services with available parts and supplies are complete.

- Corrective action-required parts and supplies that are not available in the unit are on a valid funded requisition.

- Corrective actions not authorized at field level must be evacuated to the next higher level (sustainment) with appropriate turn-in documentation.

- Scheduled services are performed at required service intervals per applicable TM or approved non-combat operations maintenance plan with no more than a 10 percent variance because of competing mission requirements.

- Routine, urgent, and emergency modification work orders are applied to equipment and reported in the Modification Management Information System (MMIS) and closed out in GCSS- Army (actions required by one-time safety of use messages and emergency safety of flight messages are also complete).

- Basic issue items and component end items are present and serviceable or on a valid supply request. Authorized aircraft flyaway items and items listed on the aircraft inventory master guide are present and serviceable or on valid supply requests.

- Maintenance advisory and information messages providing directives for weapon system software updates are applied to equipment and reported in the MMIS.

Equipment transfer and turn-in standards are largely the same since the initial MDRS proof of purpose in 2020. The latest HQDA MDRS execution order (EXORD), published in 2022, describes in-depth the deliberate and specific turn-in standards and paperwork requirements for items going to an MDRS. If losing units fail to get their excess equipment to these standards or agree to pay for the maintenance required to get them there, the MDRS staff will not accept it.

LESSONS

MDRSs and losing units have experienced a myriad of lessons (best practices and issues) with the program nearing three years of operation. With the overall aim at improving efficiency and speed with which materiel is accepted, processed, and cleared off losing units’ property books, it is worthwhile to examine lessons from all perspectives to make for a better, more effective process for all involved.

Best Practices

Department of the Army Pamphlet (DA PAM) 11-33, Guide to the Lessons Learned Program, defines best practices as validated methods or procedures that consistently show “results superior to those achieved with other means, and appears to be worthy of replication.” Several best practices identified with respect to the MDRS program include:

1. Installation Mobile Teams Formation. If manning and work requirements permit, mobile teams formed from MDRS personnel and installation or tenant division maintenance and property book specialists can enable early coordination, conduct pre-inspections, and familiarize losing units on turn-in expectations, standards, and responsibilities. These teams prove particularly useful for considerable quantities of similar equipment. They can leverage external support to promote enhanced maintenance operations and work at other site locations as applicable to best accommodate installations and unit turn-ins. Senior FORSCOM headquarters supply offices and local AFSBn staffs should consider implementing installation mobile teams when feasible to take advantage of these benefits.

2. Concept Drills Rehearsal. Rehearsal of Concept (ROC) drills performed by losing units can aid in planning and orchestrating materiel and equipment administrative statuses, associated paperwork, and transport requirements with their MDRS facilities. With these planned out and rehearsed ahead of time, it allows for smoother induction processes and reduces surprises or unforeseen circumstances during equipment induction appointments, particularly with large turnovers of unit personnel or substantial quantities of similar equipment. Rehearsals have far-reaching, positive impacts on mission success. The same is true for preparing for equipment divestiture missions and losing units should consider using them for their MDRS operations.

3. Equipment Divestitures Operationalizing. Operationalizing equipment divestitures can increase the volume of MDRS inductions because of repetition and procedural familiarity among both MDRS and losing unit support personnel. A higher headquarters can direct the turn-in of equipment of similar types on established schedules by unit and in accordance with brigade modernization plans. As inductions of all types of equipment or vehicle sets conclude, units can adjust to new equipment types and repeat the process, thus enabling efficiency discoveries as turn- ins proceed.

4. Active Leadership Participation. Predictably, active leadership involvement in the divestiture of excess equipment directly correlates to efficient and effective divestiture operations for losing units. AFSBn-Riley uses several forums to inform 1st Infantry Division leaders and sustainment personnel on MDRS processes, procedures, and results. The MDRS provides monthly updates to commanders, executive officers, S-4 officers, and support operations officers during division maintenance meetings and materiel readiness reviews. The messaging updates leaders on equipment divestment progress and provides information that allows for decisions regarding priorities and use of resources. Leaders unfamiliar and not involved with MDRS activities forfeit this ability. Their active participation provides them the knowledge and familiarity to effect positive guidance for their units.

5. Current MDRS Guidance Compliance. Understanding and executing current HQDA and local AFSBn and MDRS business rules and guidance, particularly for designated maintenance standards and required paperwork, is of paramount importance for all involved. Losing units can increase the likelihood of their local MDRSs accepting their equipment if they meet all current MDRS turn- in requirements. Unit representatives should research and seek out what they do not know with respect to the MDRS process to promote smooth divestment operations for all involved. MDRS- Riley condensed its SOPs down to a one-page document it calls “MDRS Golden Nuggets” and provides to unit leadership, S-4 representatives, and unit supply personnel to promote successful turn-ins. The MDRS increased its induction first-time pass rate to nearly 100 percent by focusing on the basics of what is needed to be successful.

6. Comprehensive Maintenance Procedures Implementation. 3rd Infantry Division noted it is essential to identify stakeholders and define each of their roles and responsibilities in comprehensive maintenance procedures before starting MDRS divestments. Every Army installation with an MDRS is unique, with various command and support relationships among all its tenant units. Having well-defined, comprehensive procedures for all supported (losing), supporting, and gaining units as applicable will facilitate improved understanding and coordination for everyone involved.

7. Maintenance Capability and Procedures. 1st Infantry Division increased the velocity of Fort Riley’s MDRS program by funding a 17-person maintenance team of contractors. The MDRS site completes all scheduled and unscheduled maintenance for the equipment being inducted. The division funds the contractors using a contract line-item number on its Enhanced Amy Global Logistics Enterprise (EAGLE) contract (an ASC program that provides maintenance, supply, and transportation support services to LRCs and AFSBns). The division purchases materiel and parts using a self-funded WBS. The Fort Riley MDRS has the capability to service and repair rolling stock, power generation, small arms, and electronics communications (ELCOM) equipment. This maintenance capability’s primary benefit is a rapid unburdening of equipment being removed from tactical units’ property books, allowing them to focus maintenance resources on authorized equipment, training, and deployment requirements. The secondary benefit is the increased velocity to ship equipment at TM 10 and 20 maintenance standards to fill shortages and increase equipment on-hand percentages of gaining units.

8. Funds Verification and Use Authorization Management. MDRS-Riley staff submit Funds Verification and Use Authorization (FVUAs) to ship equipment to gaining units once it receives shipping cost estimates. It then enters the FVUAs into Vantage, the Army’s equipment shipment data analytics platform, and monitors the FVUAs daily thereafter. This process allows MDRS- Riley staff to regularly coordinate with and relay priorities to ASC transportation account code (TAC) managers based on current MDRS missions or as seed equipment for rebuild programs. ASC TAC managers indicate they appreciate and prefer open dialogue with MDRSs to maintain effective divestiture operations.

9. Sensitive Item Service and Repair. MDRS-Riley staff inducts sensitive items (SIs) from 0800 to 1130 on Tuesday and Thursday mornings. This designated, deliberate SI timeframe increases efficiencies in time and manpower by minimizing efforts needed to inventory and store SIs. Once the MDRS staff inventories and inducts the SIs, they transfer the items to a vault for storage if the items are depot-bound. The MDRS staff opens work orders for SIs being laterally transferred and turns them over to Fort Riley’s Installation Maintenance Division ELCOM shop for maintenance. Upon completion, the MDRS staff retrieves, boxes, weighs, and measures the package equipment to obtain shipping estimates and FVUA submission.

Issues

Per DA PAM 11-33, issues are “observed, analyzed, and validated shortcoming[s], deficienc[ies], or problem[s] that preclude performance to standard and requires resolution-focused problem solving.” Some primary MDRS program issues are:

1. Missing Induction Appointments. Losing units can squander induction appointments for a variety of reasons, such as having incorrect paperwork, missing equipment sub-items, or equipment failing pre-inspections for not meeting TM 10 and 20 maintenance standards for transfer with no prior maintenance agreement. These scheduled failures create missed turn-in opportunities for other units across installations and then require makeup induction appointments, thus taking up even more time available for MDRS inductions. MDRSs generally maintain steadfast communication with losing units and send reminders as appropriate to try to prevent missed appointments. Of course, the sooner a losing unit can notify its local MDRS about desired schedule changes the better, so the MDRS staff can clear their schedule and make time available for other unit turn-ins.

2. Poor Maintenance Forecasting. Perhaps one of the biggest contributors to losing units missing their scheduled induction appointments is poor maintenance forecasting and planning, particularly if their MDRS does not have a repair capability. Units may wait too long to order replacement parts and repair vehicles and equipment to achieve TM 10 and 20 series maintenance standards, which may then cause the MDRS to not accept the items. Having enough licensed vehicle operators or no recovery assets to transport equipment to MDRSs is problematic at times for losing units, particularly from the ready reserve. Losing units must ensure they plan accordingly to achieve required transfer standards per AR 750-1, establish WBSs if applicable, or reschedule induction appointments as early as possible to prevent maintenance issues from precluding scheduled inductions.

3. Inadequate Equipment Preparation. Like maintenance forecasting and turning in at TM 10 and 20 standards, removing hazardous materials (HAZMAT) and communications equipment from excess equipment bound for MDRS turn-in is problematic at times. MDRSs generally cannot accept equipment not cleared of fuel or HAZMAT, including biohazardous and medical waste. Communications equipment is oftentimes included as sub-components of major end items or rolling stock and accounted for separately from those items. Losing units should ensure all materiel intended for MDRS turn-in is cleared of all HAZMAT and communications equipment and include pertinent paperwork if required, such as medical device demilitarization sanitation memos for medical equipment.

4. Open Work Orders for Divested Equipment. Somewhat related to poor maintenance forecasting, supported units oftentimes do not close previous work orders and repair parts requests for excess equipment due for turn-in to an MDRS. Though this does not necessarily impede displacement and repair activities at the corresponding MDRS, it does place undue burden on the supply support activity logistics pipeline, causing potential delivery of parts that are no longer needed, which must then return on additional parts shipments. Losing units can avoid unnecessary parts deliveries and lower transportation costs for the Army by diligently canceling parts and work orders once they know the parts and work are no longer needed.

5. Property Book Accountability Discipline. Occasionally, losing unit supply representatives attempt to turn in equipment not yet designated as PGI in GCSS-A to MDRS PBOs to allow for its appropriate transfer. Keeping PBOs informed of what equipment is designated for turn-in and when allows them to remain diligent and ensure all property book transactions can occur as required and in a timely manner. Including them on all MDRS mission discussions, turn-in rehearsals, and applicable pre-inspections will ensure losing units maintain effective property book accountability for all their materiel. On the receiving end for laterally transferred equipment, gaining unit PBOs must provide copies of DA Form 3161 and post the equipment to their property books so MDRS PBOs can remove the equipment from their outbound property books and transfer it to the gaining unit.

6. No Installation Lead Representative. Having no designated senior FORSCOM lead officer or staff, such as from a division G-4 office, is problematic at times for MDRS-located installations. These representatives can coordinate and work directly with their local installation AFSBn, MDRS, and garrison staffs to ensure all are aware of roles and responsibilities; verify schedules and milestones; and arrange external support as applicable. The senior FORSCOM headquarters on each installation can direct this collaboration workflow and troubleshoot or mitigate any turn-in issues before they arise.

Other Thoughts

Several other considerations that are not necessarily best practices or issues, but that the Army could consider to improve the effectiveness of its MDRS program include:

1. MDRS Instruction during Professional Military Education. The Army could incorporate MDRS subjects into its professional military education (PME) programs of instruction, particularly at the captains’ career, first sergeant, intermediate level education, and other supply and maintenance-related courses. This could familiarize junior leaders and support personnel on MDRS benefits, procedures, roles and responsibilities, and equipment transfer standards. MDRS- educated leaders and action officers could better plan and execute MDRS turn-ins, improving their speed and volume and avoiding frustration for all involved.

2. Reduction of Supply Support Activities through Parts Reuse. MDRSs accept legacy major end items from losing units, but do not process any repair parts units may have in stock for those items. Losing units must use normal SSA procedures to turn in legacy inventory and receive spare parts for their new, modernized fleets. The Army could incorporate component parts reuse processing among MDRS activities to prevent the increased workload on SSAs by augmenting MDRS staffs with materiel examiner and identifiers (MEIs), DLA-DS representatives, and access to installation recycling programs. MEIs and DLA-DS could collect serviceable repair parts for future Army or other government agency reuse upon its turn-in. Installation recycling programs could accept unserviceable items that do not require demilitarization and prepare its onward movement from Army property accountability.

3. Class VIII Medical Supplies and Equipment Requisition. The Defense Logistics Agency’s Medical Logistics Division (DHA MEDLOG) promotes “standardized medical supplies and equipment, joint interoperability of operational medical capabilities, and efficiency in the acquisition and lifecycle management of medical materiel.” As such, only DHA MEDLOG- affiliated personnel can order Class VIII medical supplies and equipment. This restriction prevents MDRS personnel from directly ordering medical items for turned in medical-related materiel to bring them up to TM 10 and 20 series standards and component availability when applicable. To prevent final equipment transfer or turn-in delays from MDRSs due to medical parts shortages, the Army could augment MDRS staffs with DHA MEDLOG personnel to be able to order medical items. Otherwise, division surgeons or installation medical offices should consider frequent collaboration with their local MDRS staffs to anticipate and be ready to order medical components for equipment as required.

VALUE TO THE ARMY

Numbers do not lie, and there is no denying the obvious impact FORSCOM units feel that have taken advantage of MDRS facilities and their many benefits over the past two and a half years. And the truth of the matter is, for every hour Soldiers are not in motor pools turning wrenches on equipment they will not use, that hour is available for them to focus on other readiness imperatives, such as fielding and training on new equipment and doctrine. Enabling Soldiers to focus on their primary warfighting responsibilities and allowing others to get rid of old, excess equipment is immensely helpful for today’s units.

The numbers speak for themselves. MDRS-Cavazos, the Army’s first MDRS facility, received and processed more than 6,700 pieces of equipment in its first four months of operation beginning in November 2020, with 4,000 items alone coming from the 1st Cavalry Division. By mid-2021, U.S. Army Alaska identified more than 3,800 excess pieces of equipment its MDRS would need to process—it received more than 800 pieces in just two months after it became operational. These are simply pieces of equipment—there is no telling how many work hours Soldiers would have spent performing maintenance checks and services; ordering and waiting on repair parts; and then installing those parts.

For a closer look at the hours, consider the nearly 7,800 pieces of equipment AFSBn-Riley processed as of 16 August 2023 since its MDRS stood up on 1 April 2021: 41,387 contracted man-hours for service and repair and another 40,368 supply-related contracted man-hours on its excess equipment per the Vantage system. This equates to more than 80,000 hours of total work performed for 1st Infantry Division and Fort Riley. Those hours are then available for Soldiers and supply and maintenance personnel to focus on new and forthcoming equipment and missions.

CONCLUSION

Army modernization requires its units to transform and adopt new technologies and equipment not seen since before the Vietnam War. Modernization for Army units requires tremendous effort from a materiel perspective, but particularly on Soldier focus, training, and familiarization on the new materiel they will receive and with which they will contest future conflicts. The MDRS program facilitates a rewarding tradeoff, letting experienced personnel focus on what they are primarily sanctioned to do—warfighters prepare to fight; support personnel acquire and sustain current and new equipment; and seasoned, professional sustainers can take care of the equipment that is no longer needed.

Endnotes are included in the attached pdf file.

Additional Resources

Follow Us on Social Media:

Social Sharing