Fielding the Global Combat Support System -- Army posed formidable training challenges. The product management office opted for a slow-and-steady approach that introduces users to the new logistics software over 150 days.

The Global Combat Support System -- Army (GCSS-Army), an Acquisition Category I major automated information system program and the largest logistics software implementation in military history, is well on its way to completion.

GCSS-Army is an enterprise resource planning (ERP) system that facilitates near real-time management of all the Army's sustainment missions. It replaces current tactical logistics management information systems, including the Standard Army Retail Supply System, Property Book Unit Supply Enhanced and Standard Army Maintenance System -- Enhanced.

It also replaces tactical financial management information systems, such as the Single Stock Fund Middleware and the Funds Control Module. These systems performed their missions well, but GCSS-Army integrates all of their functions into a single database that provides accurate, near real-time tactical logistics and financial information for all stakeholders.

The fielding of GCSS-Army has been so huge that it required the effort to be split into two waves. Wave 1 fielding began in November 2012 and was completed in November 2015. Wave 2 began in January 2015 and is projected to complete full deployment by the end of 2017.

When GCSS-Army is fully in place, the number of users would amount to a workforce that would make GCSS-Army the 45th largest employer in the U.S., just below Boeing Co., UnitedHealth Group Inc., Verizon Communications Inc. and The Walt Disney Co., but ahead of Costco Wholesale Corp., Hilton Worldwide Holdings Inc., Xerox Corp., Comcast Corp., General Electric, The Coca-Cola Co., Microsoft Corp. and Oracle Corp.

This effort, however, has not been without its challenges. Along the complicated road to implementing an Armywide overhaul of its logistics automation infrastructure, GCSS-Army program management had to confront its share of hurdles, including:

-- The complex demands of fielding an ERP solution across multiple business areas and levels of materiel management. The business areas of supply support, property book, ground maintenance, unit supply, finance and materiel management will now exist within a single database and operate in near real-time.

--- The dynamic and varying requirements flowing in from its major components (active Army, National Guard and Army Reserve). With each component varying in configuration and mission, GCSS-Army had to be designed to meet each component's unique needs. In addition, the next level of unique needs within each component also had to be considered and met, such as:

• Missile system: specific detailed system and subsystem management.

• Watercraft: onboard spare parts management.

• Logistics Readiness Center: reimbursable maintenance requirements.

• Operations and Maintenance, Army and Army Working Capital Fund funding streams.

• Special operations.

--- The extensive coordination required to field an Army in motion and transition. This required considering each unit's training schedule and possibility of deployment within the fielding window.

--- The resistance to change that has historically plagued ERP implementations. Users had grown comfortable using fairly basic, unsophisticated systems over a period of years, and in some cases decades. The basic logistics language that had prevailed since the 1970s was being replaced and required significant relearning. Finally, career legacy experts were becoming novices overnight, adding to the increased level of discomfort with the system.

--- The significant policy, regulatory and doctrinal overhaul required to reflect appropriate guidance. Historically, the development of replacement logistics software systems was, as a rule, regulation-based. In other words, designed functionality had to conform to existing regulations. As a result, the system logic, functionality and language were perpetuated from the system being replaced. The changes required to existing regulation and doctrine were minimal under previous logistics software replacements.

TRAINING AND FIELDING

One of the most demanding efforts throughout the GCSS-Army program has been the daunting new equipment (in this case, enterprise) training requirements. The fielding of logistics information systems over the past four decades has been pretty standard and followed the basic design, develop, test, schedule, train, convert and sustain events. Each fielding involved a singular logistics business area such as supply, maintenance, property book, unit supply or ammunition. This allowed the Army to define and isolate the target business area. The significantly smaller population of target users made it easier to communicate and coordinate the fielding requirements. In essence, the standalone nature of legacy logistics information systems allowed for their discrete fielding while the other business areas remained unaffected. The only distinct requirement that involved collaboration with other systems was the need to interface or communicate effectively with other legacy platforms in order to pass data back and forth.

NEW APPROACH TO TRAINING

The narrow focus of previous logistics software has allowed for a fairly stable development and delivery process involving three basic new equipment training components: a functional user manual; 40 to 80 hours of instructor-led classroom training with two instructors; and two to four weeks of over-the-shoulder monitoring in the user's converted environment. This standard approach was executed routinely throughout fielding with little variation.

In stark contrast, the decision to leverage state-of-the-art ERP software and merge multiple Army logistics business areas into a singular, integrated ERP presented a complicated challenge to program management, requiring the following key training considerations:

-- ERP systems are complex. How can we minimize the significant learning curve common to ERP implementations?

---What type of approach will we need to reach more than 160,000 users representing seven business areas, across three components?

--- How can we execute the eventual training solution while managing cost and schedule?

--- How can we ensure a smooth and seamless transition of knowledge to the institutional base and troop-school complex?

THE SOLUTION

The answer came gradually, beginning in 2006, when we realized that implementing GCSS-Army would be too complex to perform in two- to four-week sessions per unit, as was the standard with predecessor systems. As the fielding team shaped the length and specifics of the conversion process, the training team began conceptualizing the training progression. The progressive training model took hold during a successful Wave 1 effort and continued to evolve during the early stages of Wave 2 implementation.

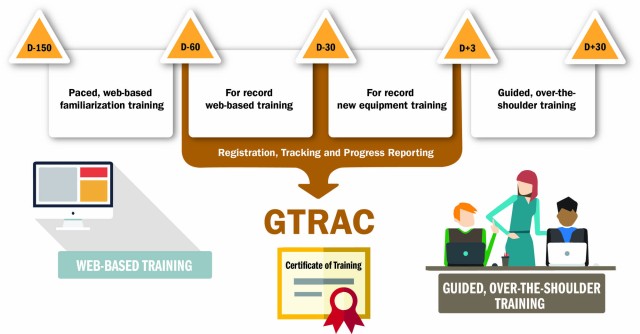

The solution is a progressive training model that begins early in the fielding process and spans 150 days. The intent is to provide the user with a steady diet of GCSS-Army content throughout this extended learning period. The training model, developed internally and consistent with training theory, has several components that combine to create the equivalent of a full "semester" of GCSS-Army training. This model enables each user to begin the learning process early, committing a few hours weekly, and gradually to absorb a huge amount of content, thus flattening the learning curve leading to post-conversion activities. At that point the user is guided through a series of routine processes, allowing for practice in a live system. According to Juan Torres, a GCSS-Army trainer at Fort Bragg, North Carolina, "The users are learning faster during the over-the-shoulder guided training. They like being able to ask questions as they execute their daily mission in a live system."

The final step in the GCSS-Army fielding is to provide the new equipment training package to the respective U.S. Army Training and Doctrine Command institutions and regional troop schools.

SPREADING THE WORD

The final step in the GCSS-Army fielding is to provide the new equipment training package to the respective U.S. Army Training and Doctrine Command institutions and regional troop schools.

The first component is web-based training. Thirteen modules are hosted on the GCSS-Army field-facing website, and a robust training center (http://gcss.army.mil/Training/WebBasedTraining.aspx) provides a suite of lessons intended to familiarize the new user with the basics of GCSS-Army, including the structure, language, process flow, basic navigation and access administration. If the entire training process is crawl-walk-run, web-based training is the "crawl."

The second component is the GCSS-Army Training and Certification (GTRAC) System, a dynamic and progressive training management environment that allows users to register and take certificate-producing and introductory web-based training specific to their business area, as well as formal new equipment training. The training now becomes more targeted to the specific user's role within their business area. The user is introduced to the theory and logic of processes within a realistic scenario, and simulations of the live system allow the user to gain experience executing the mechanics of each process. (See our "Learning GCSS-Army the right way" video for a detailed explanation of the GTRAC process.)

Next is instructor-facilitated training. Formal classroom training varies from four to 40 hours, depending on the business area. This is followed by over-the-shoulder support, which puts into practice all of the concepts learned during familiarization web-based training and formal new equipment training. A qualified trainer walks the user, who now has full access to data from their business area, through the execution of a daily process battle rhythm in a live environment. The processes are repeated, with the trainer gradually backing away as the user becomes comfortable.

The last component is the user manual plus, a dynamic, all-inclusive, searchable online reference manual that contains cue cards, transaction guides, job aids and simulations that guides a user through detailed process steps. The content is easily accessed by the user within GCSS-Army, is available in multiple formats and is downloadable.

Full speed ahead! Armed with an improved version of the training strategy used for all of Wave 1 and through fielding group 20 of Wave 2, the product manager continued to execute the Wave 2 fielding unabated.

NO PLAN SURVIVES REALITY OF EXECUTION

Faced with the need to streamline training to maximize cost avoidances, the program management office, in coordination with the Combined Arms Support Command, Army G-4, and the assistant secretary of the Army for acquisition, logistics and technology, developed a hybrid training module to create a more cost-efficient training approach. The model allows specific tailoring of training that includes length, how much is online or instructor-led, and length of over-the-shoulder, guided, live system training. The combination of delivery modes will vary by Army component, region, personnel availability and cost. The standard approach uses the online training suite of tools to deliver new equipment training to the active Army while providing centralized classroom training to the National Guard and Army Reserve; as a result, the program management office is able to get critical training in the hands of users faster. This modified version of the progressive training approach will be applied beginning with group 21 out of a planned 30 fielding groups.

TRANSITION TO SUSTAINMENT

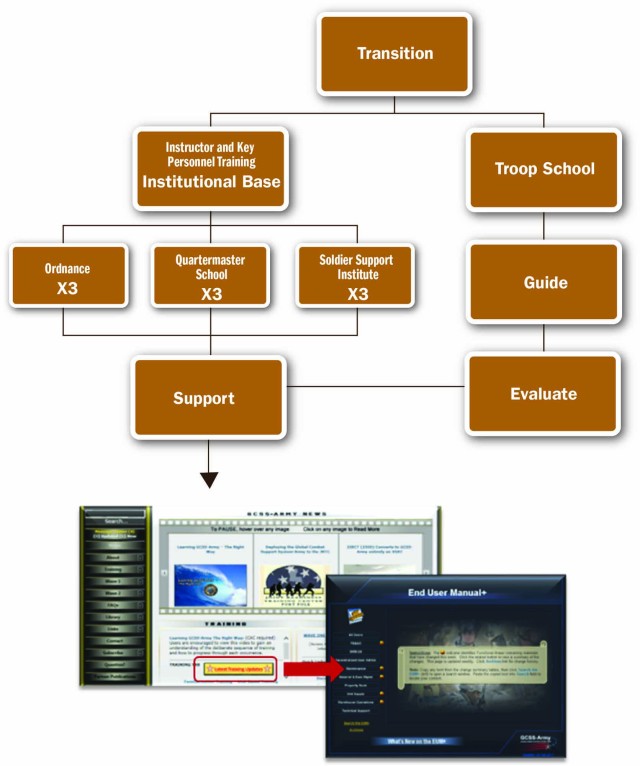

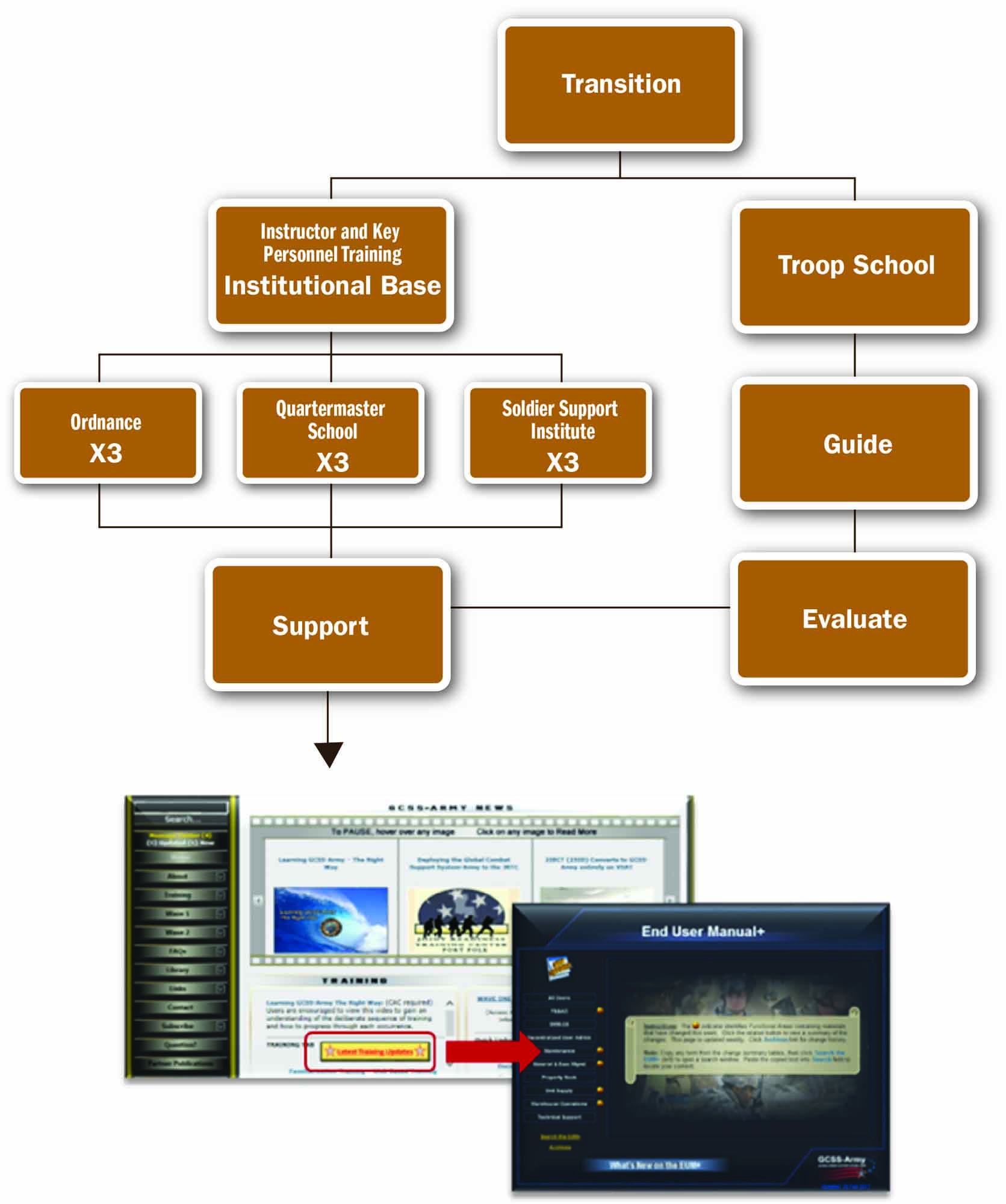

No training strategy is complete without an approach to transition the knowledge to the institutions (quartermaster, ordnance and finance schools). In the GCSS-Army plan, the full new equipment training package is provided to the respective U.S. Army Training and Doctrine Command institutions and regional troop schools. GCSS-Army provides three iterations of instructor and key personnel training to the school training staff, and provides guidance and coaching to the troop school training administration.

TURNKEY UPDATES

To ensure that the training institutions have the very latest information, GCSS-Army posts a link to all of the changes to training content on its website, which then takes the user to the end-user manual plus location where the changes are detailed. This update occurs weekly, allowing the training institutions to keep programs of instruction current. GCSS-Army also built in a user satisfaction survey at the end of training to receive direct, ongoing feedback. This feedback proves vital as GCSS-Army continues to field Wave 2.

SOME USER FEEDBACK

--- Live system access. Ideally, access to a live system would be more realistic and effective. The concept is not new and has been used several times to train legacy systems. The standalone or decentralized nature of legacy systems made it fairly easy to develop a base scenario within a training instance with reset capabilities. In a classroom setting, students would be guided through scenarios and required to execute processes to achieve the school solution. Once completed, the box would simply be reset to the beginning state. This approach becomes significantly more complicated and costly when your instance is the entire production system--in fact, this one topic would merit an article of its own. The approach we took was to capture actual simulations of a development system that allowed students to execute processes that mimicked the live system.

--- Training needed to be longer. This feedback was difficult to fathom since the training period was 150 days long. We assumed users wanted more classroom training and built that into our over-the-shoulder approach, which not only extends training but involves actual instructors guiding users through daily processes in their own live system.

The ability to adapt to unexpected challenges, or simply to create more user-friendly training modules, will drive GCSS-Army to success. With an over 90 percent approval rating based on user surveys, the GCSS-Army Program Management Office feels confident that full deployment will be another success story.

CONCLUSION

Having cracked the code with a hybrid template for new equipment training, program management can now leverage the training development, delivery and sustainment model to ensure that the Army at large can certify and recertify its population of GCSS-Army users well into the future. In addition, the model is flexible enough to accommodate future software implementation efforts.

The GTRAC learning management component has issued more than 766,000 certificates of training, covering eight business areas and six supplemental areas, to more than 122,000 GCSS-Army users from unit level through the Army G-4 and the Army Materiel Command. At the current rate, GCSS-Army expects to exceed 1 million certificates issued by October 2017.

For more information, go to our website training center at http://gcss.army.mil/Training/WebBasedTraining.aspx; or contact the training team at usarmy.lee.peo-eis.mbx.gcss-army-training@mail.mil.

This article is scheduled to be published in the July-September 2017 issue of Army AL&T Magazine.

Related Links:

U.S. Army Acquisition Support Center

"On The Right GTRAC" on USAASC website

Global Combat Support System -- Army

Social Sharing