The Department of Defense obligated more than $27 billion in fiscal year 2010 contracts to support military engagements in Iraq and Afghanistan, according to "Department of Defense Contractors in Afghanistan and Iraq: Background and Analysis," a 2011 Congressional Research Service report by Moshe Schwartz and Joyprada Swain. While political and military leaders focus on the drawdown in Afghanistan, many Soldiers, Sailors, Airmen, and Marines will continue to rely on the contingency contracting process to accomplish their difficult missions.

As a contingency contracting officer who has led contracting teams in both Iraq and Afghanistan, I am often asked, "Why does the contracting process take so long?" To adequately answer this question, one must understand that the contingency acquisition process has three primary stakeholders: requirement generators, resource managers, and the contracting office. Each of these stakeholders must continue to work hard to streamline the acquisition process. This article will focus on the requirement generators and introduce a model that will help streamline and standardize requirement packages.

REQUIREMENT GENERATOR RESPONSIBILITIES

The requirement generator is responsible for assembling a complete package that includes a detailed description of the required work or supply item, market research, and pricing information. If the package is incomplete, the contracting office often will return the package to the generator with specified corrections. Incomplete requirement packages delay the acquisition process and often result in a failure to deliver requirements to the right place at the right time. This scenario increases the frustrations of both the requirement generators and the contracting office. Most importantly, it hurts the mission.

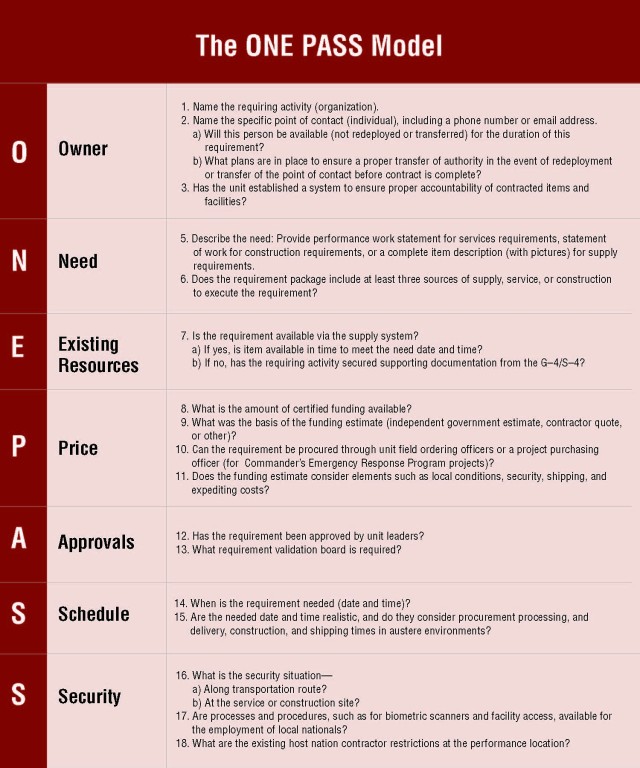

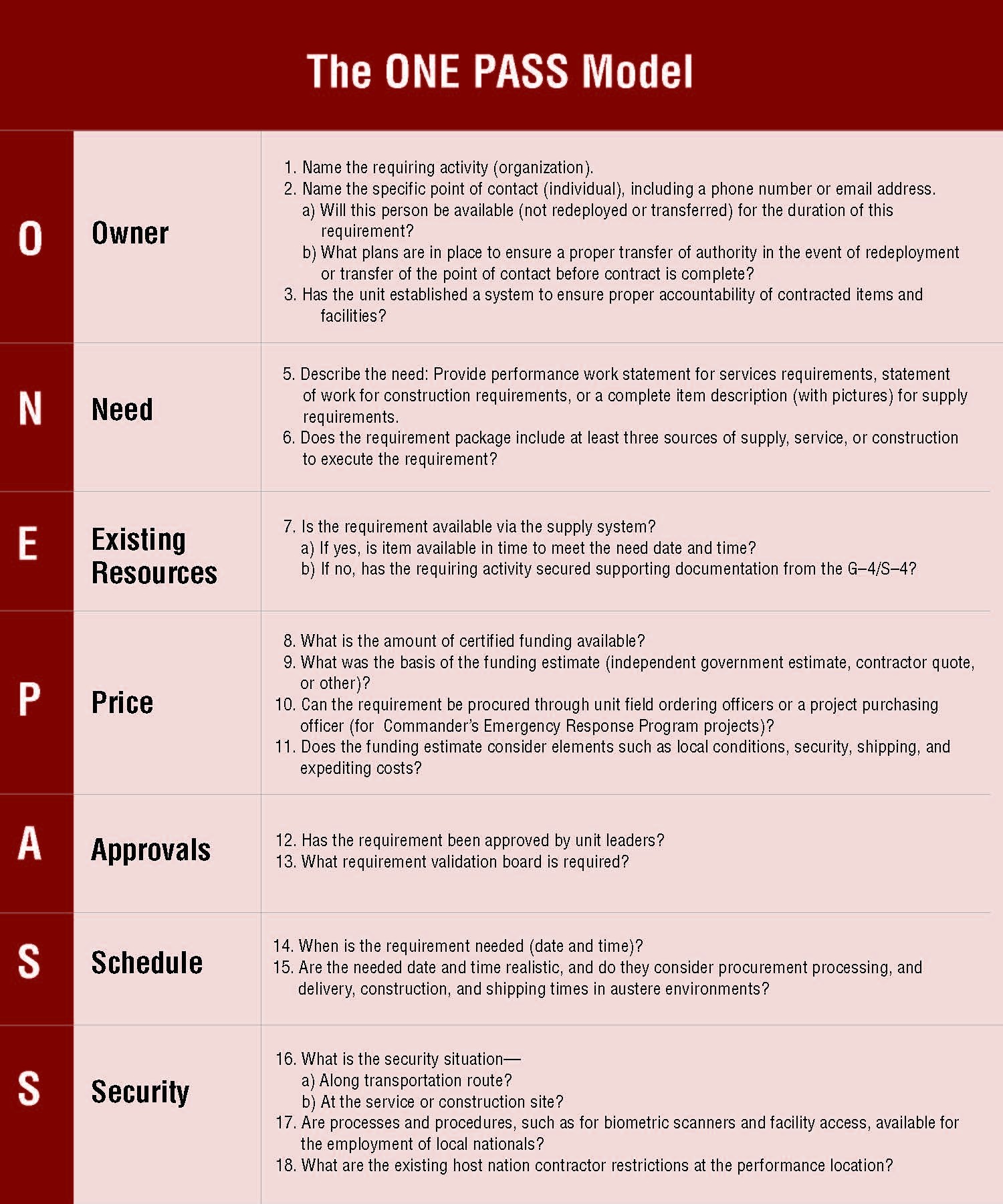

One way to decrease acquisition lead time is a simple tool called the "ONE PASS" model, which can be used by requirement generators to expedite and standardize requirement package preparation. This tool can, in some cases, enable requirement package approval by the contracting office on the first look.

THE ONE PASS MODEL

Deployed Soldiers are trained on the execution of a 9-line medevac request. This life-saving tool provides data in a standardized format that enables users to clearly and quickly articulate critical information to supporting units. Effective use of the 9-line has proven to expedite supporting unit response and, in doing so, has saved countless lives.

Similarly, the ONE PASS model aides requirement generators in organizing and standardizing their requirement packages. The model directs the requirement generator to consider the ownership, needs, existing resources, prices, approvals, schedules, and security elements of their requirements. (For details, see the chart below.)

Expediting the contingency contracting process requires concerted efforts of the requirement generators, resource managers, and the contracting office. The ONE PASS model is introduced here as a simple tool to help requiring activities to better prepare acquisition packages in the deployed environment.

Admittedly, the ONE PASS model is not designed to answer every conceivable question the contingency contracting officer may have. The ONE PASS model will, however, help both the requirement generators and the contracting office to expedite requirement package approval by streamlining and standardizing how information is provided to the contracting office. Use of this model can enhance the probability of getting the required work or item delivered to the right place at the right time.

___________________________________________________________________________________________

Maj. Jamie M. Rhone is an Air Force contracting officer who has led contingency contracting teams in both Iraq and Afghanistan. Feedback relating to this article (to include enhancements to the ONE PASS model) can be sent to jamie.rhone@pentagon.af.mil or to Army Sustainment at usarmy.lee.tradoc.mbx.leeeasm@mail.mil.

___________________________________________________________________________________________

This article was published in the March-April 2013 issue of Army Sustainment Magazine.

Related Links:

Browse Army Sustainment Magazine

Social Sharing