WATERVLIET, N.Y. (Feb. 2013) -- The Secretary of the Army recently acknowledged what the Watervliet Arsenal workforce has known for nearly 200 years, their skilled craftsmanship and machining capability is unequaled anywhere in the Department of Defense. The Honorable John M. McHugh has designated the Watervliet Arsenal as a Center of Industrial and Technical Excellence (CITE) for cannons and mortars.

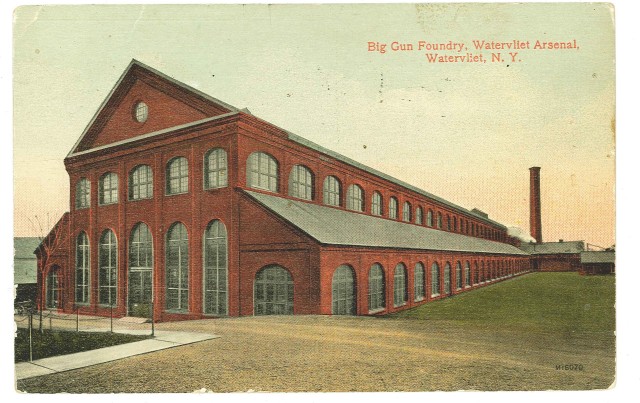

According to McHugh, the Watervliet Arsenal possesses the skills and capabilities related to cannon and mortar manufacturing not shared by any other industrial facilities in the Army.

"It (Watervliet) has the nation's only large bore cannon production facility and maintains proprietary processes for heat treating and rotary forging…and is relied on to produce today's most advance high-tech, high-powered cannon and mortar weaponry," McHugh stated in his memorandum.

This news was greatly welcomed by the Arsenal's senior leadership.

"Given that we are in an intense competitive business environment for fewer defense contract dollars, this announcement by the Secretary of the Army came at just the right time," said Col. Mark F. Migaleddi, the Arsenal commander.

"The Secretary's statement speaks volumes about the Arsenal's capability and capacity to rapidly respond to the urgent needs of our warfighters and to do so with unequaled quality," Migaleddi said. "But beyond the equipment and buildings that help define our capability is our highly skilled workforce who works tirelessly to manufacture the products that in the end help our Soldiers to come home safe."

Although the CITE Certification does not necessarily direct more contracts for the Arsenal, said Joe Turcotte, the Arsenal's director of Installation Management, it may cause more weapon program managers to give the Arsenal another look during the procurement process.

"The Secretary just stated that nowhere else in the Defense Department can the Arsenal's core competency to manufacture cannons and mortars be found," Turcotte said. "Therefore, the logical reasoning should be that the Arsenal is no longer just an option but a first choice for cannon and mortar manufacturing."

Turcotte also said the designation may have other implications for other military services to look more closely at Watervliet for their cannon and mortar manufacturing.

Beyond potential defense contracts, another significant effect of the CITE designation is the Arsenal may now more freely enter into public-private partnerships to perform work that will enhance its manufacturing core competencies.

"We may now more easily work with private industry to share and leverage the Arsenal's equipment, facilities, and workforce skills to the betterment of the private company and to the Arsenal," Turcotte said. "What this means is that private industry may tap into the Arsenal's great resources, such as heat treatment, rotary forging, and machining, to assist them with their product lines."

Such private-partnership may not only keep the Arsenal's skills sharper, but may also reduce the Arsenal's cost of operation, Turcotte said.

Managing the Arsenal's cost of operation go beyond that of simply being efficient. And that is why public-private partnerships are such a big deal.

How the Arsenal is funded to conduct operations and maintenance often surprises community leaders and elected officials. Unlike other Army installations such as Fort Bragg in North Carolina or Fort Sill in Oklahoma, the Arsenal does not receive Congressional funding for its base operations.

All funds required to maintain and operate the Arsenal comes from a process called a Revolving Fund. A Revolving Fund is an account where Arsenal income to fund its operations comes from its revenue that is generated through military sales of its products.

Additionally, the Arsenal operates very similar to a civilian manufacturing plant. Just as Ford Motor Company or General Electric are very sensitive to profit and loss accountability, the Arsenal cannot operate at a loss, either. And, although the Arsenal is a government-owned and --operated manufacturing center, there is no guarantee of future work. But unlike Ford and GE, the Arsenal cannot operate with a profit. Any savings that are realized during the production cycle are returned to the customer, who in the end is the American taxpayer.

Through public-private partnerships, the Arsenal may be able to better maximize its resources, such as buildings equipment, and manpower, to lower the cost of its operation, which in turn may lower the cost of its products to the U.S. military.

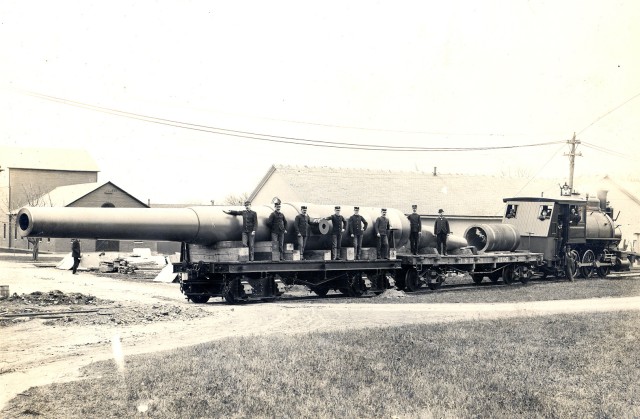

The Watervliet Arsenal (pronounced water-vleet") is an Army-owned-and-operated manufacturing facility located in Watervliet, New York. The Arsenal is the oldest, continuously active arsenal in the United States, having begun operations during the War of 1812. The Arsenal will celebrate its 200th anniversary in July 2013.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $100 million.

Related Links:

Watervliet Arsenal Twitter Page

Watervliet Arsenal Flickr Page

Watervliet Arsenal Slideshare Page

Social Sharing