In upstate New York, three generations of the Frament family call Watervliet Arsenal home. From an industrial management specialist to an environmental protection specialist, the family is part of a storied workforce that spans almost 200 years. Today, the employees at Watervliet Arsenal are relied upon to produce the most advanced, high-tech, high-powered weaponry for cannons, howitzers, and mortars.

Halfway across the country at Red River Army Depot in Texas, employees are making history. The High Mobility Multipurpose Wheeled Vehicle recapitalization facility is able to produce more than 40 vehicles per day, up from just 12 in 2004.

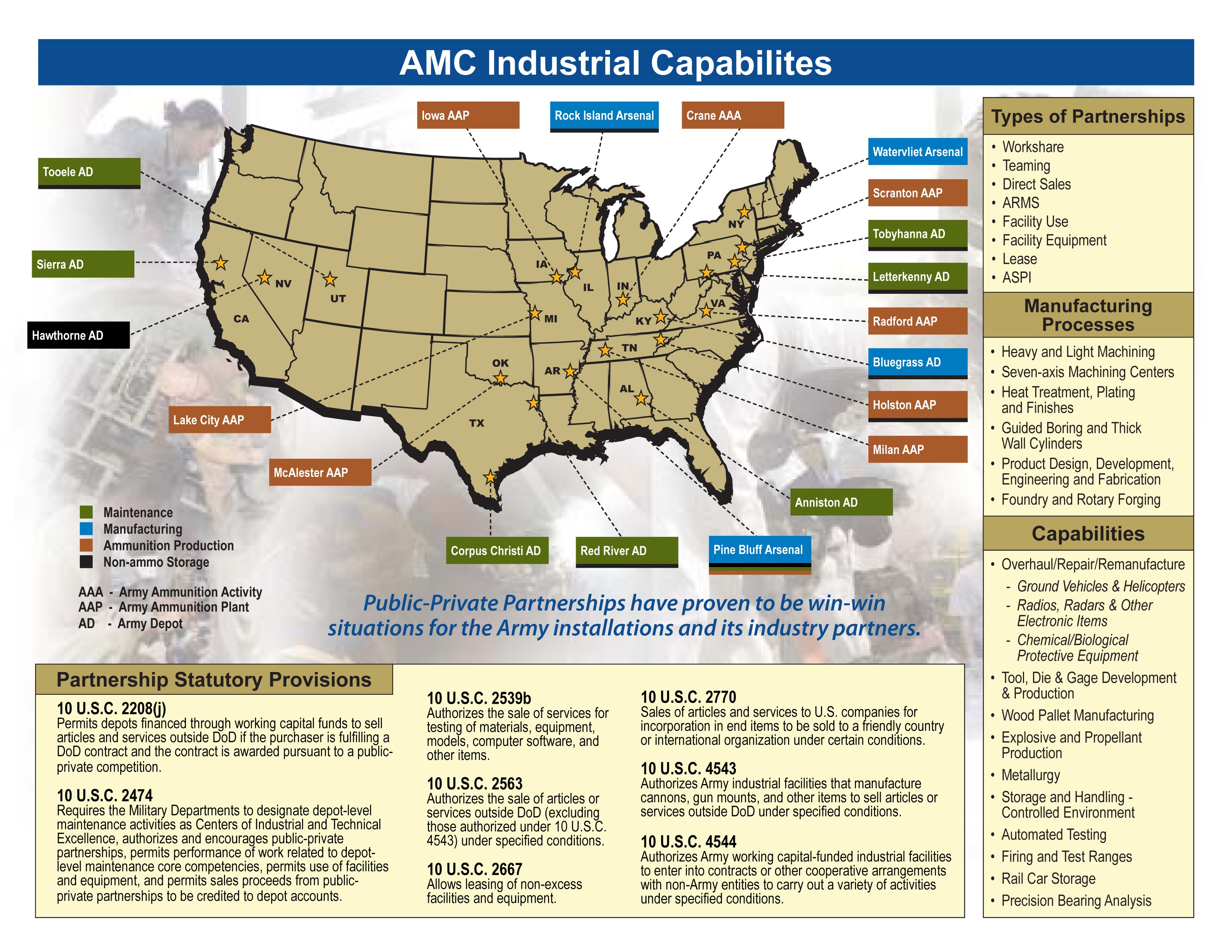

Watervliet Arsenal and Red River Army Depot are part of the U.S. Army Materiel

Command's (AMC's) Organic Industrial Base. Made up of arsenals, depots, and ammunition plants across the nation, the Organic Industrial Base has facilities, manufacturing capabilities, and thousands of highly skilled, experienced professionals who provide combat readiness on a daily basis. These skilled craftsmen are uniquely qualified, one-of-a-kind, second and third-generation industrial artisans.

After a decade of supporting a high operational and deployment tempo, AMC and its Organic Industrial Base are in transition. As the command shifts from supporting an Army at war to refitting and sustaining that Army, production, storage, and workload requirements at its Organic Industrial Base facilities are expected to decrease. Preserving these 20-plus facilities and their workforces, considered a national treasure because they provide capabilities that in many cases do not exist elsewhere in the

United States, is a top priority for AMC's leadership.

With this shift in AMC's focus and industrial base workloads, an enormous opportunity exists for the private sector. Through the Public-Private Partnership (P3) program, companies can take advantage of the critical capabilities and skill sets developed over the past decade by the Army's Organic Industrial Base. By bringing in new opportunities and business for development, the Army can maintain support critical to the warfighter.

HOW THE PROGRAM WORKS

P3 is an agreement between an Army facility and one or more private industry entities to perform work or to use the Army's facilities and equipment. While the program has existed for more than 16 years, it is growing in visibility and becoming a key strategy to sustain the industrial base.

The goal of P3 is to fully leverage the power of partnerships to enhance and preserve AMC's unique organic industrial facilities, processes such as welding and testing, and personnel, while offering private industry access to those capabilities for mutual benefit. Partnership arrangements result in more effective fulfillment of Army contracts by private industry, at lower cost and reduced risk to industry partners. They also sustain production lines and other systems, as well as the critical skill sets of our nation's industrial artisans.

In executing partnerships, the Army Industrial Base depots, arsenals, plants, and centers provide services that are either not available in the private sector or not cost-effective for private industry to provide. Partnerships can take many forms, including:

• Teaming or work sharing, which incorporates a combination of Army depot and contractor facilities and employees to produce or repair systems, equipment, and components. For example, Raytheon Co. and McAlester Army Ammunition Plant in Oklahoma partnered in a work-sharing agreement in 2011 to produce Joint Standoff Weapons and the GPS-guided Excalibur projectiles. McAlester provided the trained workforce, while Raytheon provided the testing and inspection.

• Purchasing and direct sales, whereby private-sector firms purchase articles or services from an Army installation. For example, starting in 2011, Honeywell International Inc. purchased services from Corpus Christi Army Depot in Texas to repair and test gears and seals for weapon systems.

• Leasing, whereby firms lease facilities and install their own equipment, or lease facilities and depot-owned equipment to produce goods and services for government or commercial customers. For example, Safety Management Services Inc., an internationally recognized corporation that provides a variety of risk management services to commercial clients and government agencies, began a partnership with Tooele Army Depot in Utah in 2009 to conduct product explosive sensitivity and reactivity testing at their facilities. SMS uses the depot's test site for about 30 weeks out of the year.

BENEFITS TO INDUSTRY

The P3 program benefits industry in several unique ways. It facilitates private industry access to U.S. Army Centers of Industrial and Technical Excellence and their advanced-technology equipment. Industry can take advantage of opportunities at places like Tooele Army Depot, which owns and operates a fully equipped machine shop with water jet, electro-discharge, and milling machines; or Blue Grass Army Depot in Kentucky with more than 1,200 structures including igloos, supply warehouses, maintenance buildings, and munitions sheds.

Industry can also take advantage of the diversified, highly skilled, and deployable workforce. Red River Army Depot has more than 3,000 multi-skilled government employees who have technical experience and capabilities including the design, fabrication, and manufacturing of a wide variety of items, from specialty parts to unique prototype weapon systems and vehicles. And as more industry partners enter the unmanned aerial vehicle marketplace, the workforce at Corpus Christi Army Depot or Tobyhanna Army Depot in Pennsylvania can provide repair and maintenance using methodologies honed by Lean Six Sigma initiatives.

Finally, industry can protect its bottom line by using established facilities equipped with modern tooling and manned with trained and ready workers, rather than constructing new plants or training new personnel. In return, the Army improves operational efficiencies and lowers the cost of products and services by maximizing output and potential.

CONCLUSION

Partnerships generate significant revenue and jobs for the Army, leading directly to sustainment and expansion of organic industrial capabilities. In FY11, AMC had P3 partnerships with more than 350 businesses, generating more than $370 million in revenue and supporting 3,500 government and private industry jobs.

As the transition from combat to sustainment slows the operational tempo at Industrial Base facilities, opportunities for public-private partnerships will grow considerably. AMC is in the process of developing a comprehensive strategic approach to business development to maximize those opportunities. Part of the plan includes leveraging major commercial trade shows, where business decisions are often made, for industries such as automotive and heavy machinery.

The goal is to increase P3s steadily, at the same rate as U.S. economic growth, and ultimately to drive enough partnerships to maximize the capacity at each of the Industrial Base arsenals, depots, and plants. This growth is necessary for the U.S. Army to sustain the critical skills and capabilities it needs to maintain readiness for future operations.

For more information about the P3 program or how industry can partner with an AMC depot, arsenal, or ammunition plant, go to www.amc.army.mil/amc/partnership

opportunities.html or contact the AMC P3 program manager at 256-450-7128.

Social Sharing