TOBYHANNA ARMY DEPOT, Pa. - Protecting state-of-the-art electronics equipment from the damaging effects of electrostatic discharge is a top priority here.

Military members count on Tobyhanna employees to properly handle and package electronic devices to ensure reliable systems are delivered to the war zone. Continuous training, inspections, and research and development projects help the depot stay one step ahead of ESD.

Static discharge can upset the normal operation of an electronic system, which could lead to malfunction or failure. Many of the components repaired at the depot are susceptible to damage caused by ESD and the work force is required to follow established prevention guidelines.

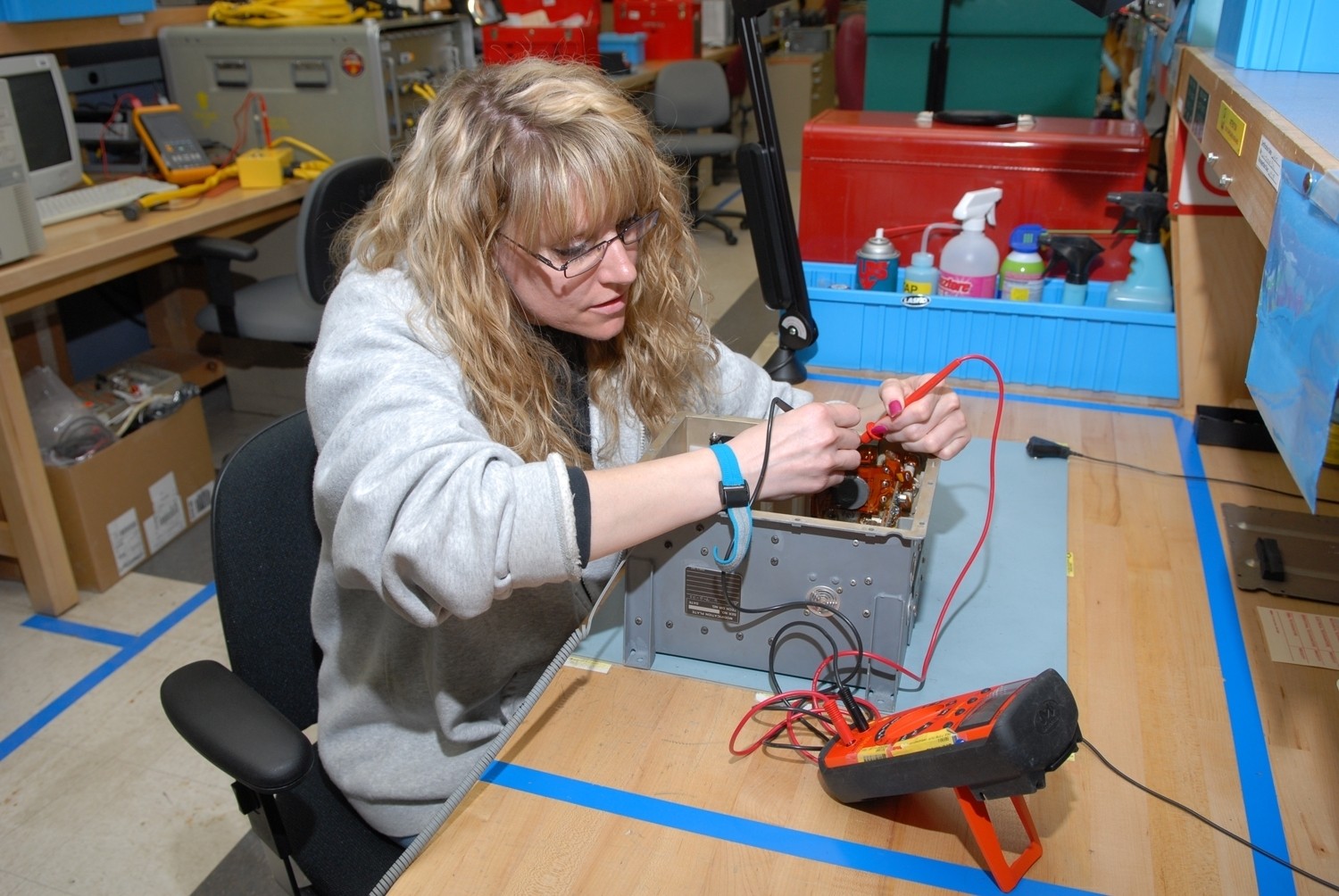

For example, personnel use protective packaging materials, and special markings, workstations, clothing, equipment and handling procedures to protect sensitive items.

"We owe it to the warfighter to provide reliability in electronic repairs through innovation and insight," said Larry Weber, ESD coordinator. "It's everyone's responsibility to wear or use the proper equipment to prevent ESD."

Weber is an electronics engineer in the Productivity, Improvement and Innovation Directorate's Process Engineering Division.

Static electricity has been an industrial problem for centuries, according to an article posted on the Electrostatic Discharge Association Web site. The article mentions that as early as the 1400s, people have been taking precautions to prevent ESD. Furthermore, the age of electronics brought with it new problems; as electronic devices became faster and smaller, their sensitivity to ESD increased.

For instance, fire control and navigation systems on equipment such as the M-1 tank and F-18 aircraft are controlled by electronic microchips so sensitive that a charge of 30-50 volts of static electricity may cause the equipment to malfunction during deployment or combat missions, according to experts at the Defense Supply Center Columbus, Ohio.

Controlling electrostatic discharge begins with understanding how electrostatic charge occurs.

"When the humidity drops to about 40 percent or less is when you start having problems [with ESD]," Weber said, explaining that common materials and activities can generate an electronic charge. "We want to remove the charge before it can cause damage."

Weber described how a person walking across the floor generates static electricity as their shoe soles contact and then separate from the floor surface or how sliding an electronic device into or out of a bag, magazine or tube generates an electrostatic charge.

Even items such as Styrofoam cups and sheets of paper must be placed outside a 6- to 12-inch perimeter around the work surface depending on the sensitivity of the components.

Items like wrist straps and mats provide a path from an individual's body to the ground discharging any accumulated energy slowly, Weber noted.

Many defects can be traced to careless handling and packaging of items sensitive to electrostatic discharge, according to information posted on the DSCC Web site.

Tobyhanna's training policy charges managers, supervisors and employees with developing and maintaining team and individual technical competence by making good use of every training opportunity.

Janelle Marchione supervises 23 people who support the Multiple Threat Emitter System and mini MUTES by overhauling their transmitters. As chief of the Transmitter Branch, she has developed a team-based approach to keeping her staff at the top of their game. Using a method that encourages teamwork, branch employee's work together to maintain proficiency and monitor current practices to prevent ESD incidents.

"We are giving them the knowledge of what they should and shouldn't be doing in a positive manner," she said. "I see improvement every day. This new way of doing business has created a sense of pride among the workers. Now they're working together as a team."

Employees in work areas around the depot supplement their ESD education almost every day by gathering information from classroom and online training courses, home team meetings or Army regulations.

"The regulation is a detailed list of dos and don'ts in regard to ESD," said Ray Ragnacci [S. Abington Twp resident], electronics mechanic. "It also clearly states what's expected of us."

Transmitter Branch personnel turn to Matt Beavers when they need ESD equipment.

"I make sure everyone gets the mats and wrist bands they need," Beavers said, adding that he also does periodic inspections to make sure everyone is following procedure.

New to the depot, the electronics mechanic helper admited to knowing very little about ESD when he started. "I now know that any kind of static charge can blow out a board worth thousands of dollars."

Weber recommends that "since ESD is such a complex issue, it's best to use protective equipment at all times."

Len Ferlick has been bombarded with information throughout his career.

"It's very important for people to get into the ESD program early so using the tools becomes second nature to them, " said Ferlick, an electronics mechanic.

Ferlick disassembles radios and circuit cards, and replaces components for the Command, Control and Computers/Avionics Directorate's Flight Control Systems Branch.

"Working with electronics equipment is the heart of our daily mission," Ferlick said. "Everyone here is trained in ESD procedures because at some time, they will have to work with sensitive items."

Marchione agrees. "ESD awareness is important because of the quality of the product we're putting out, and it's what the depot expects."

Tobyhanna Army Depot is the Defense Department's largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to ground terminals for the defense satellite communications network. Tobyhanna's missions support all branches of the Armed Forces.

About 5,600 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the Communications-Electronics Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., CECOM LCMC's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing