WATERVLIET ARSENAL, N.Y. (Dec. 20, 2012) -- Watervliet Arsenal's historic Big Gun Shop has seen a lot of action since the first brick and mortar were laid nearly 130 years ago. From the 16-inch battleship guns that could fire a 2,200 pound projectile 23 miles, to the 155mm cannons for the U.S. Army Field Artillery's new M777A2 lightweight howitzers, have flowed through the wooden doors of this great factory.

So, it should not be a surprise to anyone venturing through this 1,300-foot-long facility today to still see some type of manufacturing taking place.

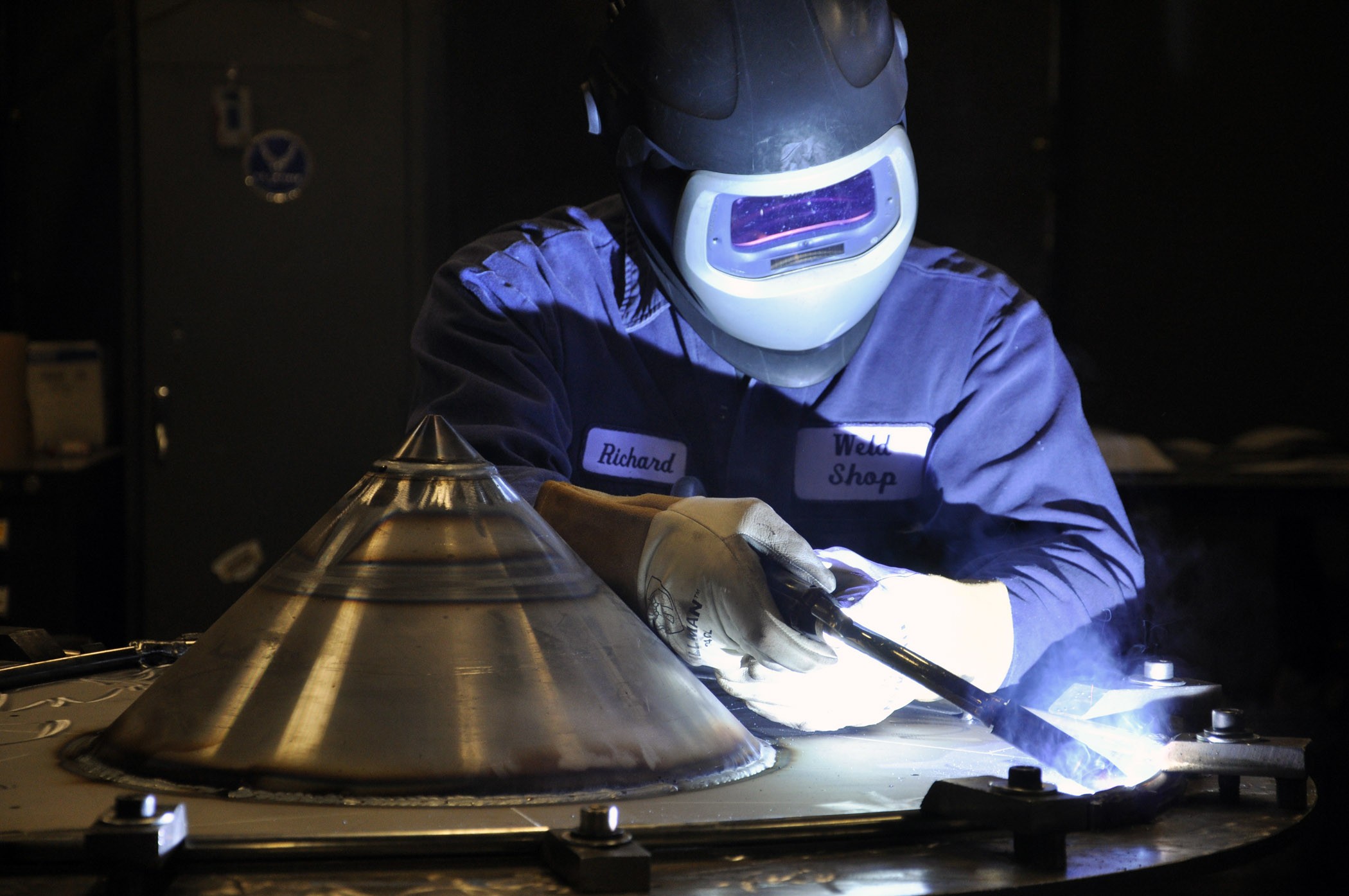

In the bowels of this brick building is one of the Arsenal's most critical functions -- welding. Of all the manufacturing functions, the welding section seems to be the true growth industry at the Arsenal. The arsenal has increased its workforce from five welders just two years ago to the 14 it has today.

These welders have been extremely busy this past year working on such warfighting products as mortar baseplates. In fact, they assembled in 2012 more than 300 baseplates for the 120mm mortar system.

Looking at the finished baseplates may seem to the untrained eye that this job must have been a simple manufacturing process. But for the welding team, they had to weld together 57 parts using more than 90-feet of weld to get the baseplates into their final configuration.

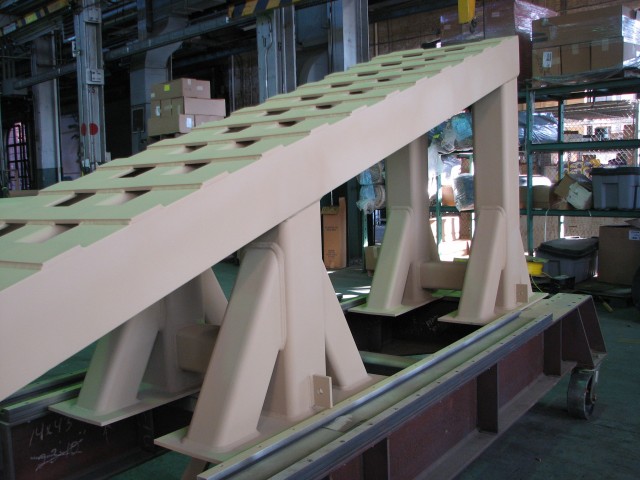

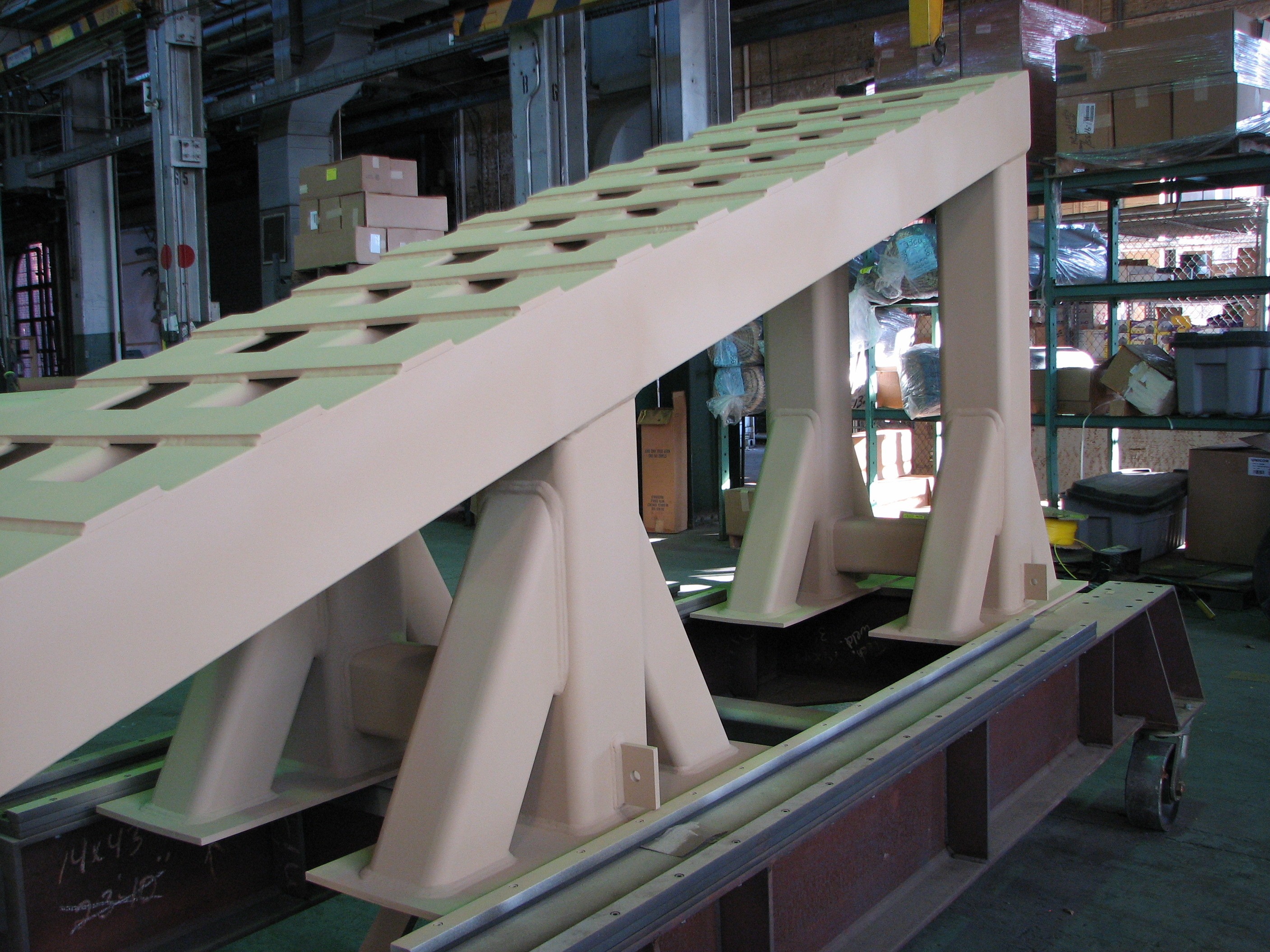

As if welding baseplates, muzzle brakes, and barrel clamps wasn't challenging enough this past year, doing some prototype work for the M1A2 Abrams Tank was also laid on the shoulders of the welders.

"In the 10 years that I have been here, we have never had a welding job of this size or challenge," said Greg Stone, the Arsenal's welding team chief. "Every welding skill imaginable, from the blowtorching of parts to tig welding, was used to manufacture this plumb and sync ramp for Abrams Tanks."

But the challenge of manufacturing a non-standard product for the Soldiers was met with uncanny teamwork, Stone said.

"The excitement by my team to design the weld plan and then build this Abrams Tank ramp was unbelievable," Stone said. "Everyone wanted to be a part of this project because they knew the challenge would test every skill that they had."

"We even had to fabricate the work station because most of our work is no larger than the size of a 120mm baseplate," Stone added.

How the Arsenal was able to become part of this Abrams prototype ramp work speaks volumes about the power of synergy that is unmatched anywhere in the Department of Defense.

The Watervliet Arsenal manages the production aspect of the tubes and various assembly parts for cannon and mortar systems, but relies on its on-site collaborator, Benét Laboratories, to conduct the research, design, and prototype development for those systems. Located at the Watervliet Arsenal, Benét Labs is a department of the Army research development, and engineering facility. Their research and design capability is often leveraged by the Arsenal to improve production methods and products.

"The program manager for the Abrams tank system came to us about one year ago and asked us to design and build a prototype plumb and sync ramp," said Clyde H. Bascue Jr., the Benét Lab's Abrams program leader, and lead for the plumb and sync ramp development.

The problems with the current ramps are two-fold, Bascue said.

"The current plumb and sync ramp that is in use throughout the force was designed for the M60 tank and was not built by a manufacturer, but by logistics centers at each installation," Bascue said. "Therefore, the quality standards vary from installation to installation."

Additionally, because the ramp was not redesigned for the M1 Abrams tank, as the tank backs up onto the ramps its tracks are often unevenly distributed over the supporting structure. Analysis has proven that due to the tank tracks not being evenly distributed, significant failures have occurred on the ramp welds. Thus rendering the ramps useless, Bascue added.

"This was a great opportunity for us to first analyze the current ramp and then design and build a new product at the Arsenal," Bascue said. "For nearly 10 months, my team, consisting of Patrick Hickey, Paul Watson, Scott Fadeley, and I leveraged many of our in-house capabilities, including computer modeling and simulation, to design plumb and sync ramps that not only increased the ramp's weight bearing capacity from 60 tons to 80 tons, but also decreased the weight of the individual ramps by nearly 1,000 pounds."

To move the concept from a computer design to a prototype, Benét Labs turned to the manufacturing center at the Watervliet Arsenal.

"We can never underestimate the synergy that we have at Watervliet by having those who design within a five-minute walk from those who will turn those designs into a product," Bascue said. "Having the weld shop fabrication operation collocated with us allowed us to engage the welders during each step of the prototype construction."

On Nov. 28, Benét sent two sets of the prototype ramp to Aberdeen Proving Ground for testing.

Plumb and sync is a tank crew task that is achieved after bore sighting. The tank crew will back the tank up onto the plumb and sync ramp to align all sights to improve the accuracy of the fire control system.

As this story was being written, the weld team was observed repairing a 16-foot gap in the Arsenal's fence line. A car driver going through the City of Watervliet failed to make a turn and drove into the Arsenal's fence knocking down two large fence sections. Due to concerns about the Arsenal's security at the open fence line, the welders were called in to do a quick repair. Once again, proving just how good they are. The welders were able to repair two severely damaged fence sections to their pre-accident condition.

The Watervliet Arsenal (pronounced water-vleet") is an Army-owned-and-operated manufacturing facility located in Watervliet, New York. The Arsenal is the oldest, continuously active arsenal in the United States, having begun operations during the War of 1812.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high tech, high powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $100 million.

Related Links:

Watervliet Arsenal Twitter Link

Watervliet Arsenal's history, tradition, and pride help restore guns, community spirit

Watervliet Arsenal joins shipping wars, saves taxpayer dollars

Army.mil: Science and Technology News

Watervliet Arsenal Flickr Link

Watervliet Arsenal Slideshare Link

Social Sharing