LOS ALAMITOS, Calif. -- The Army Reserve Center project is in the "punch list" stage with safety officials, contractors and District project delivery teams making final inspections before furniture is installed and the customer takes possession in October. The ARC is the headquarters for the 79th Sustainment Support Command which was activated Dec. 1, 2009.

Soldiers, family members and civilians of the 79th Sustainment Support Command will soon have a new headquarters, organizational maintenance area and acres of parking at the Joint Forces Training Base here. The work is all part of a nearly $25 million project managed by the U.S. Army Corps of Engineers Los Angeles district.

Andy Stevens of Retrofit Services Company from Rancho Cucamonga, Calif., was onsite Sept. 12 putting the finishing touches on the computerized building management system that will control the state-of-the-art energy efficient heating, ventilation, and air conditioning for the headquarters building. The system uses multiple condensers and is nearly 30 percent more efficient than systems of just five years ago.

"This one [building zone] is calling for one stage cool, fans on, temperature is 72 [degrees] in the zone and the set point is 72, so it's doing just fine," said Stevens. "You can change your occupancy status at any time, emergency override it, shut it down and we do have the chemical alert push-buttons that will close all dampers inside and out."

The alert buttons are located throughout the facility and once activated because of an attack or a release of hazardous chemicals, no air is allowed in or out of the building to protect the occupants, according to Maj. Phillip Oster, the U.S. Army Corps of Engineers Los Angeles district's Santa Ana Resident Office deputy who oversees the project.

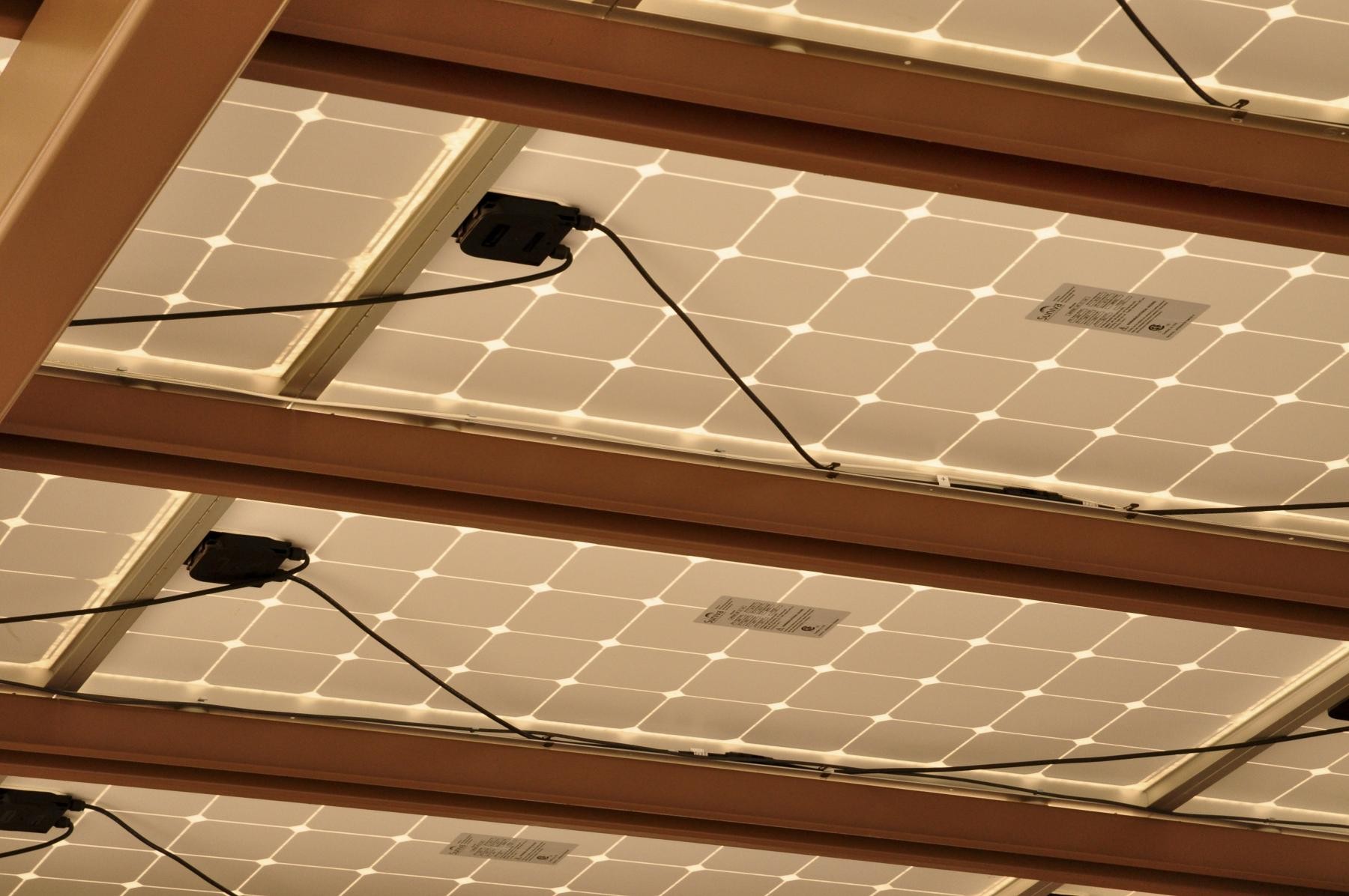

To reduce construction costs and increase future savings, the project is using eco-friendly features, like re-cycled material, and in the case of the covered parking lots, they will generate energy with a photovoltaic system. The contract partner's quality assurance manager for the project explained the feature.

"At peak, they produce 375 KVA [kilovolt-amps]," said Edward Desmond, Cox Construction of Vista, Calif. "In theory, it's enough power to offset the footprint of the Army Reserve Center building."

While not designated a net-zero facility, the extensive use of energy efficient materials during construction will enable the photovoltaic system to actually return power to the Los Alamitos grid, off-setting the operating costs of other buildings on the base, according to Desmond.

The Energy Policy Act of 1992 mandated the use of "low flush" urinals in government facilities. This project takes it a step further with water-free urinals. The USACE Engineer Research and Development Center estimates that they pay for themselves in six-months to three years and the cost savings don't end there. All new Army construction is designed to satisfy the Silver-level standards of the Leadership in Energy and Environmental Design rating system, in accordance with the U.S. Green Building Council guidance.

According to Oster, the project is in the "punch list" stage with safety officials, contractors and District project delivery teams making final inspections before furniture is installed and the customer takes possession of the ARC in October.

Social Sharing