Corpus Christi Army Depot artisans will soon be able to repair UH-60 Black Hawk main rotor blades using a new technology that will save time and money for the depot.

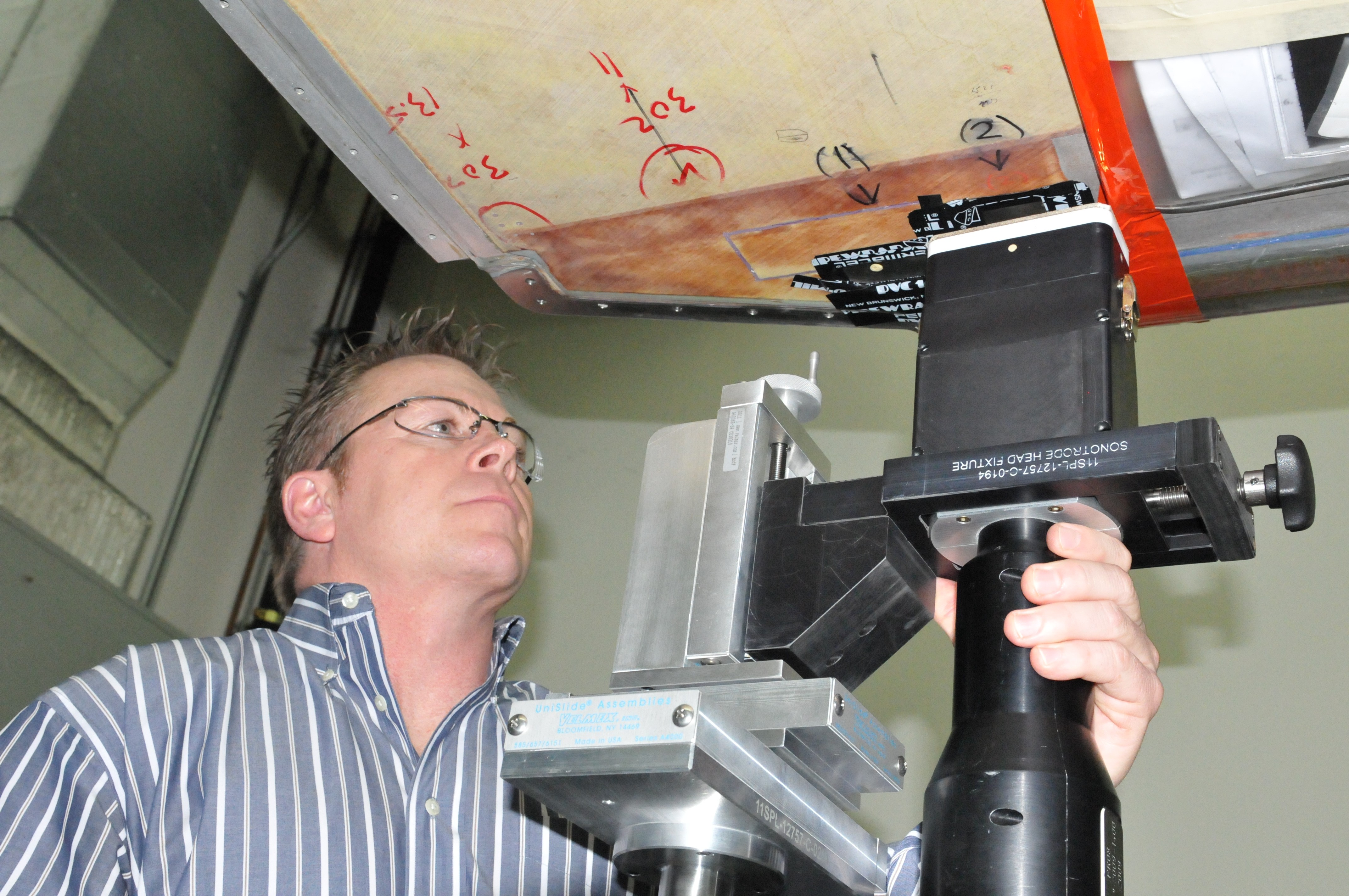

Avion Solutions Inc., a veteran-owned small business providing high-quality, specialized engineering, logistics, software development and technical services, visited CCAD to demonstrate repairing seven UH-60 rotor blades using ultrasonic shot peening technology, March 6-8.

The depot coordinated with Aviation and Missile Research Development and Engineering Center (AMRDEC) to bring the portable technology for repair in-house and on the field.

"This will ensure what the depot is doing for flight critical components meets the requirements of our depot's maintenance overhaul standards," said Col. Christopher Carlile, CCAD Commander.

Due to space limitations at the shot peen shop, repairs to the UH-60 main rotor blades cannot be accomplished until the ultrasonic shot peening equipment is in full swing. CCAD currently has to refurbish the blades at OEM facilities which incur a high dollar repair cost along with more time spent away from the depot.

"Ultrasonic peening has been recently considered an alternative to conventional shot peening due to its versatility in establishing localized repairs on the field," said Alberto Rodriguez, Materials Engineer.

The U.S. Army Small Business Innovation Research Commercial Pilot Program is funding Avion Solutions Inc. to begin the initial steps of using the ultrasonic shot peening equipment.

The new computerized technology has the ability to shot peen small localized process areas in approximately 36 seconds. In September, Avion Solutions will come back to the depot to train the artisans that will use the new equipment.

"This capability will increase our readiness and how we can repair the blades and increase the turnaround time," said James Jabal, Materials Engineer.

"I really think this is getting into process improvement and how we make it better, faster and cost effective," said Col. Carlile.

Social Sharing