REDSTONE ARSENAL, Ala. -- Necessity truly is the mother of invention at the Prototype Integration Facility.

Most of the inventions conceived at the Aviation and Missile Research Development and Engineering Center, Engineering Directorate PIF were inspired by war fighters' needs for rapid solutions to shortfalls or problems within the theater of operations. From something as big as a Bell 407 helicopter modified to become an Iraqi armed reconnaissance helicopter so the Iraqis can support their own air space, to something as small as a crew extraction bracket designed to allow Soldiers to pull open a damaged Humvee door to extract a wounded Soldier, the government employees and contractors at the PIF work together to create real world solutions.

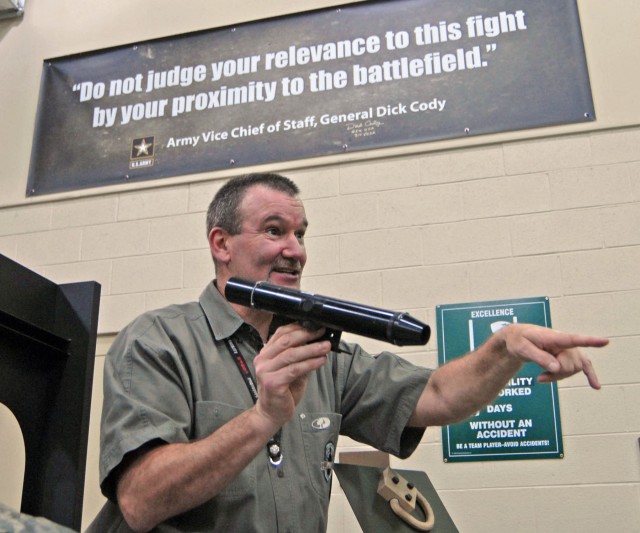

"We've got one of the best jobs in the Army. There's a lot of pressure and a lot of requirements to support the Soldiers, but we take it personal to make sure we give them the best possible solution that's quick and cost-effective," PIF aviation special projects lead T.J. LaPointe said.

When there is a need in the theater on a weapon system or an Apache helicopter or an MLRS or any kind of vehicle, the people at the PIF set out to not only find a solution but to create a prototype and test it as well. Many of the inventions are lifesaving solutions that the PIF takes from conception to reality with a rapid response so that war fighters have them in hand as soon as possible.

"When we say rapid -- a lot of development projects are years in the making, we do it in months, sometimes weeks. For some smaller items or mission equipment we may end up doing in such a short time that we're able to get it in the hands of the war fighter really quickly and get true feedback back from them," LaPointe said.

Seven PIF inventions have won "Army's Greatest Inventions" and the facility itself has contributed to previous AMRDEC best lab awards. LaPointe often receives commendations for his work, but he would rather share the limelight with everyone involved. Although the PIF's crew extraction bracket is not a high tech solution, it was named one of the Army's greatest inventions because it is a high impact solution that saved countless Soldiers' lives.

The brackets allow the locking mechanism of the Humvee doors to be overcome so that an injured Soldier can be removed from the vehicle in time to save his life.

"We don't want to leave somebody out that had a hand in it. It's easy to take credit, it's much tougher to share with a bigger volume that says this whole group had a hand in this," LaPointe said. "It's not fair to say, 'Hey, I did a great job' when it was a team, a village, behind that."

The PIF was tasked with creating an improved personal effects container prototype. Its display at the facility reminds everyone why their lifesaving inventions are so important. It contains items such as a fallen Soldier's uniform, dog tags and medals. The PIF team interviewed a wide range of male and female staff to get the best ideas, and then created a prototype that looks like a WWII footlocker but is made of a hybrid of eucalyptus and walnut so that it impervious to water.

Because Soldiers today are part of what LaPointe calls the "Xbox generation," the PIF has teamed with the Industrial Operations division (a sister Engineering Directorate division) to house a visual graphics lab. The VIZ LAB creates training videos using 3-D models and animations that allow Soldiers to learn how to perform specific tasks. These visualizations are a better way to teach Soldiers instead of simply handing them a maintenance manual.

"You can take young military maintenance guys and let them read the manual and you've lost them in less than five minutes. By the second page they're bored to tears. And then you go out on the aircraft and they didn't retain what they learned in a classroom," LaPointe said. "But if you give them a video, real quick they pick it up, they understand it, they retain it and there's an 80-95 percent retention rate when they work on the aircraft."

The VIZ LAB's team of engineers, graphic artists, software developers and 3-D modelers works to illustrate complex ideas, concepts and processes through the visualizations. The lab's primary mission is rooted in the training arena, but a byproduct of the visualizations is the creation of movies and marketing videos. Just like the visualizations, the marketing videos try to capture the viewers' attention and feed them relevant information that they will retain.

The VIZ LAB can take any idea and illustrate it. In some cases this saves money because customers can see the product before it's built and make some adjustments or changes based on seeing the models. The VIZ LAB created its own marketing video to explain its processes and the types of products it makes.

"We can fool some people with these videos because some of these scenes are so realistic that they do look real, they look like live-action footage when in fact they're 3-D models and animation," VIZ LAB project lead Cody Flores said. "Before anything was even built for the Iraqi Armed 407, we took the design plans that the PIF came up with and actually modeled it from those plans and created a conceptualization of the helicopter. When the Iraqis saw this video, they thought it was real. They thought the helicopters were out there flying and we were taking pictures of it when in fact it was just a model."

When the Iraqi government asked the U.S. government to take a commercial Bell 407 and modify it to become an armed scout reconnaissance helicopter, the PIF team executed the Program Executive Office strategy to take three commercial helicopters and incorporate several Supplemental Type Certificate components, military weapons, and Aircrew Survivability Equipment.

"This was a Team Redstone effort to provide the most cost effective and functional components and equipment to meet a quick turnaround time," Jimmy Dunaway, a government product lead for the Iraqi Armed 407, said. "It's not just the PIF, it's a joint endeavor of the Security Assistance Management Directorate, the Program Management Office Armed Scout Helicopter, the Aviation Flight Test Directorate, the AMRDEC's Aviation Applied Technology Directorate out of Fort Eustis (Va.), Aviation Engineering Directorate, and other Aviation and Missile Command elements -- a lot of organizations and bases or agencies. This has truly been a Redstone enterprise to get these helicopters ready. In a two-year period, we had three helicopters up and in flight test."

The PIF's customer base stretches across the Department of Defense. Inventions displayed at the facility include an electronic display module for Navy Sea Hawks, an infrared zoom laser designator mounted on Apache helicopters, a flare dispenser cable for Chinook helicopters, and a gunner glove or mitt for an M240 machine gun. All of these are lifesaving solutions that the PIF put into the theater very quickly.

In 2004 a customer said he needed an infrared solution and he needed it quick because Army helicopters were crashing into each other at night. So the PIF invented a covert lighting system.

"When we say invent it we mean we go to Fort Belvoir's night vision labs and find out what's the highest intensity IR light emitting diode and then we package it and send the design in 15 days, prototype it, test it, and then carry it down to Fort Rucker. They put it on an aircraft and do a flight test because they've got the ranges for it," LaPointe said. "They come back and say, 'It worked so well, it gave six miles of visibility with night vision goggles. You have five weeks to put 250 of them on the back of our Apaches.'"

The PIF can best be described as a rapid response engineering center. It is a Government Owned Government Operated enterprise established to economically meet compelling and urgent needs of the U.S. government. The PIF has the necessary expertise and facilities to rapidly design, fabricate, integrate, test, qualify and field hardware solutions.

"Colonels come in and tell us that in their prior career they'd see a solution and two years later it still hadn't made it to the battlefield. Here they see real world solutions happening in a matter of weeks or months. Everything here has a rapid urgency to it and we take a lot of pride in making sure we get that solution to them quickly and cost-effectively," LaPointe said.

Social Sharing