When it comes to Army footwear for mountainous terrain, the other shoe -- well, combat boot -- has clearly dropped.

For years, Soldiers fighting in the upper elevations of places such as Afghanistan have benefited from the development and fielding of the Mountain Combat Boot. Last spring, however, feedback from those same Soldiers indicated that its evolution needed to take the next step, toward a more breathable boot for warmer weather.

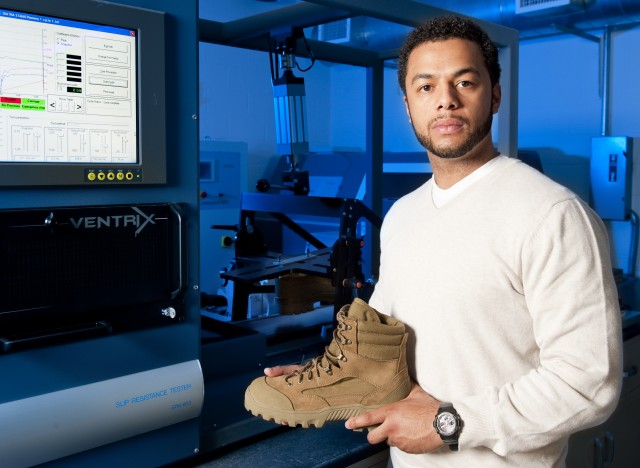

"We wanted to respond to Soldiers' needs," said Ben Cooper, footwear project engineer in the Footwear Performance Laboratory at Natick Soldier Systems Center. "(Program Executive Office) Soldier and (Product Manager Soldier Clothing and Individual Equipment), along with Natick, tried to come up with a solution.

"We went to industry and said, 'Hey, what do you have for us? What do you have that would fulfill these performance requirements that we have right now?'"

As it turned out, industry had nothing domestically available at the time to cool off Soldiers' feet.

"A boot like this literally did not exist," Cooper said. "Most hiking boots out there … are going to have waterproof membranes in them."

Two manufacturers -- Belleville Shoe Manufacturing Company and Wellco Enterprises, Inc. -- were awarded contracts to produce the Hot Weather Mountain Combat Boot.

"Industry responded," Cooper said. "They were able to meet the challenge."

As Cooper pointed out, the manufacturers were asked to add greater breathability but not lose any of the well-received Mountain Combat Boot's characteristics in the process.

"We wanted it all," Cooper said. "We wanted a boot that's going to have a rigid platform. It's going to be abrasion-resistant, something that's going to provide ankle stability, something that is light, something that is going to be more breathable in hot-weather environments."

Unlike the original mountain boots, the hot-weather versions aren't waterproof. Instead, the new boots have perforated leather and drainage eyelets in the insteps to provide better airflow.

The manufacturers produced the boots in six months, an impressive turnaround by anyone's measure.

"I don't think it can be done much faster," Cooper said. "We're really excited to be able to collectively respond to Soldiers' needs. There was a need, it was identified, and we responded as rapidly as possible to get this done. And we never lost sight of why we were doing it."

Cooper said the boots will now go to Soldiers in the field for limited user evaluations and to the lab for rigorous testing.

"We would like to start to get boots on Soldiers' feet that will be going to Afghanistan, have them provide us feedback on the boot, and, hopefully, we'll be able to synthesize that information and be able to even dial it in further," Cooper said. "We've got to do a lot of lab testing. We're going to be constantly pushing industry to improve what they already have."

On the threshold of testing, Cooper said he is happy with the new boot so far.

"We want this to be a true hot-weather boot," Cooper said. "The Hot Weather Mountain Combat Boot is roughly twice as breathable as the Mountain Combat Boot."

Cooper expects the new boot to be fielded in spring 2012.

"Not only are we trying to provide the best possible material solution, but we're trying to provide a safe piece of equipment to Soldiers," Cooper said. "Our intention … is to far exceed where we even have it now. We've just scratched the surface."

Social Sharing