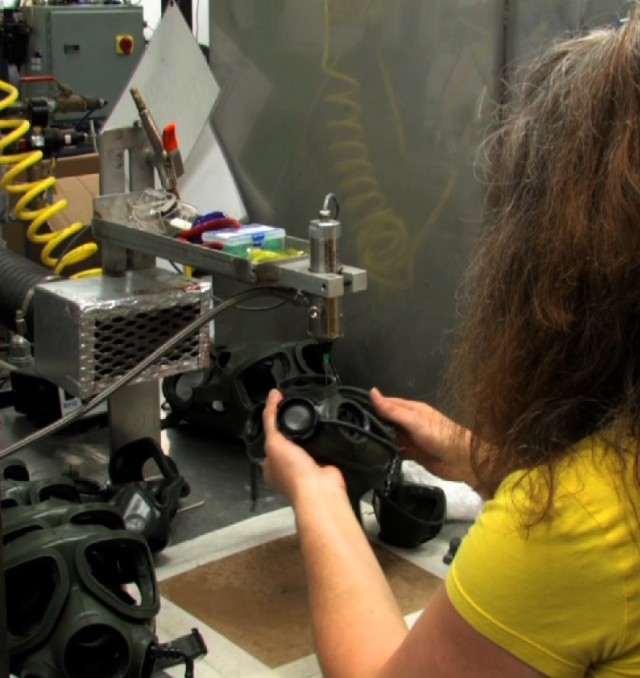

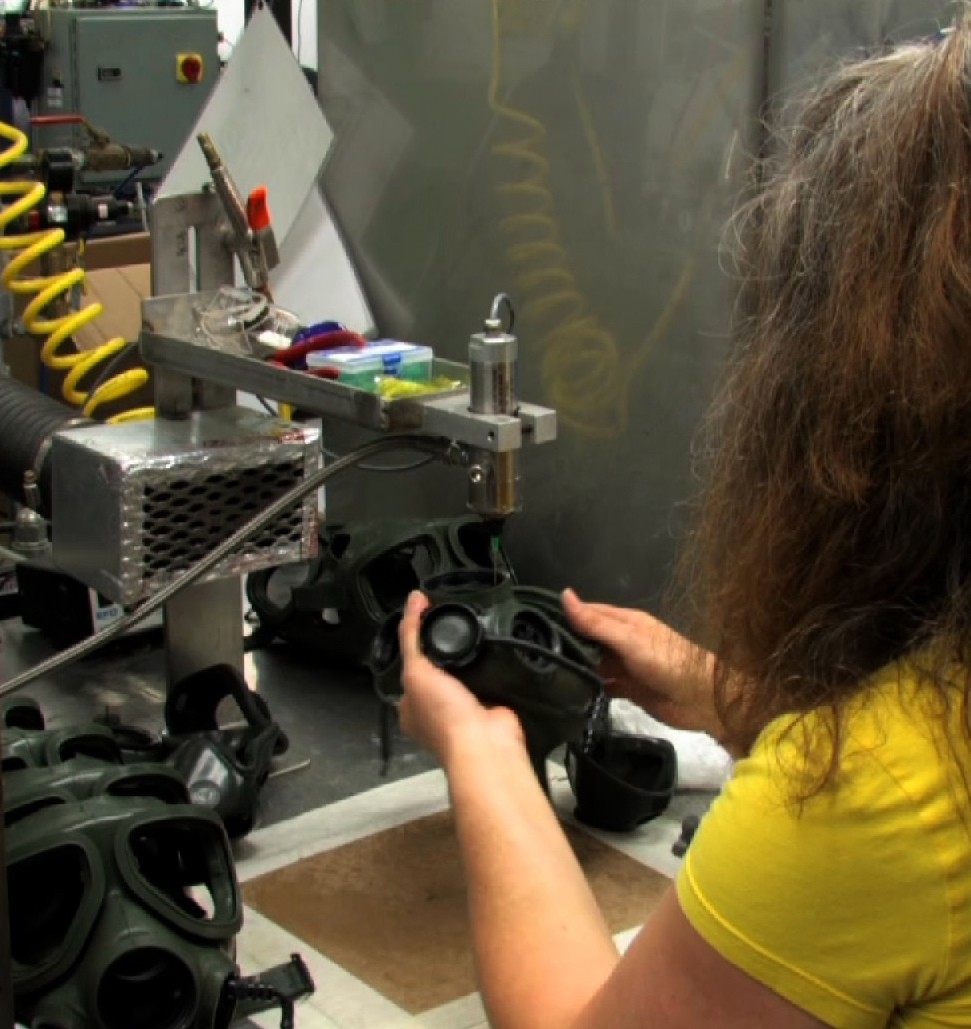

PINE BLUFF, Ark. -- Optimizing production at a premium cost is the standard not the exception in the Directorate of Chemical and Biological Defense with the development of the M40 mask.

Since April of 2007 the production of the M40 masks have steadily increased without an increase in cost.

"We were producing 450 masks [daily] with 27 to 28 people and we've increased that to 675 [daily] with 33-34 people," said Tom Grossman, Chief of Production in the CBD Plans and Programs Division "We did that by going through lean transformation, tying work content together, and changing the order of operations."

The packaging of the masks is an example of a change in production, which equated a cost and time savings.

Originally the masks packaging consisted of several layers of plastic and foam boxes with a cost of approximately $17 per mask.

With coordination, the cost for packaging was reduced to approximately $5 per mask.

"Over the past four years, we have increased our output yearly," Grossman said. "We understand what the lessons are and how we can use these lean tools and the lean six sigma process to get better as an organization."

Recently, the directorate hit a major milestone in mask production.

"We recently completed production of our 600,000th mask," Grossman said.

The next goal is 750,000 masks completed by July 2012.

The Army is the primary customer for the M40 mask but the division also provides masks across all the services.

Social Sharing