WATERVLIET ARSENAL, N.Y. -- In upstate New York, organizational pride and a touch of science recently trumped Department of Defense standards to the tune of approximately $14 million. That is the size of the contract awarded last month by the Department of the Army to the Watervliet Arsenal to replace more than 400 breechblocks for the Army's lightweight 105mm howitzer system -- the M119A2 towed howitzer.

In 1987, an agreement was reached with the British Royal Ordnance Factories to produce the howitzer under license by the U.S. as the M119 to replace the M102 howitzer. It entered service with the U.S. Army's 7th Infantry Division in December 1989.

Although the Watervliet Arsenal did not manufacture the overall end item platform, it did, in conjunction with the Army's Benét Laboratories, manufacture the system that made the howitzer lethal -- the 105mm M20A1 cannon assembly.

The Arsenal always looks beyond what is called the Technical Data Package or TDP during and after the manufacturing process in search of product improvement.

Sometimes, however, product improvements may take years before they are accepted, if they are accepted at all, because the Army directs manufacturers, be they government-owned or from private industry, very specific standards via the TDP and manufacturers cannot deviate from these standards.

This breechblock modification upgrade kit is a direct result of a little bit of patience intertwined with a pursuit of excellence.

According to Jeanne Brooks, a mechanical engineer with Benét Labs, "For more than 20 years, Arsenal and Benét Lab engineers have supported and monitored user feedback on the cannon in search of improvement opportunities."

So, Benét engineers and Arsenal machinists never stopped trying to perfect the breechblock. They recently proposed to the Army's Program Manager, Towed Artillery System (PM TAS), who is charged with fielding and maintaining the howitzer, a redesign that will not only improve Soldiers' safety, but also may reduce potential downtime.

Why a redesign?

Several years ago, Benét Labs discovered a safety-related flaw in the breechblock, albeit one that did not put Soldiers at immediate risk. This finding was significant enough, however, to effect a change to the technical manual that required artillery crewmen to verify and measure the firing pin protrusion after every live firing, Brooks said.

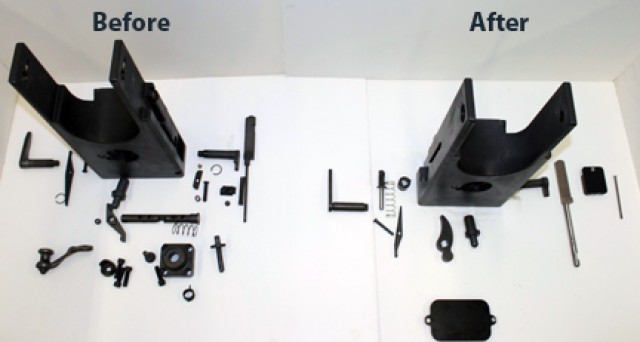

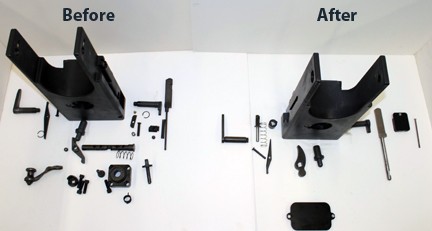

The breechblock improvements under this new modification will reduce the number of breechblock parts by 30 percent, which should reduce maintenance cost and downtime because there will be fewer parts affected by wear and tear.

The redesigned breechblock also eliminates the recock mechanism by incorporating this function into the side of the breech ring. Removal of the recock mechanism from behind the weapon removes the need for a Soldier to reach behind the cannon in the path of the recoil during a misfire to recock the weapon. This is a significant safety gain while also eliminating the need for a recock tool.

"This new modification will initially be integrated into about half of the Army's M119 howitzers," said Randell Huffy, the Arsenal's Production Control & Program Management Chief.

Because of the long lead time associated with acquiring the raw materiels, the Arsenal will begin production around mid-2012, Huffy said. The projected man-year gain from this new contract is 24 over a three-year period for the Arsenal.

Social Sharing