ANNISTON ARMY DEPOT, Ala. " It was so quiet you could almost hear a pin drop in the Combat Vehicle Repair Facility.

No tanks or Strykers looped around the test track.

Even the engine test cells were silent.

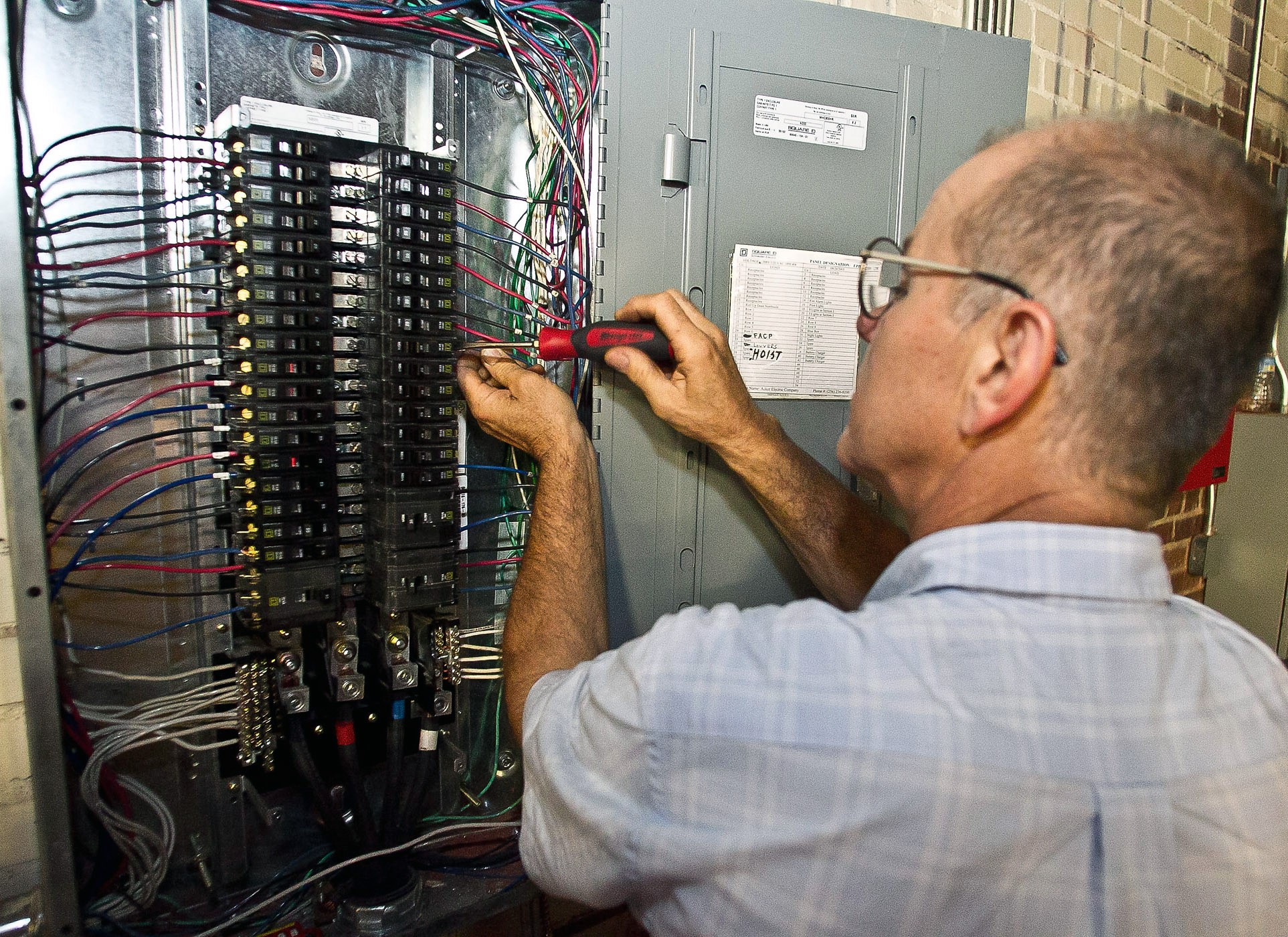

Twice a year, during shutdown, the only movement in the Nichols Industrial Complex is by utility trucks and a handful of men and women toting tools between buildings.

These are the worker bees of shutdown, which recently occurred the week of July 4 " employees of the directorates of public works and engineering and quality " who keep the depot running by performing preventative maintenance and other tasks on equipment and infrastructure while production comes to a halt.

“This is pretty standard in any industrial operation because it allows us to go in and do preventative maintenance while the equipment isn’t in use,” said Tommy Gaines, director of public works for the depot.

The two directorates prepare for shutdown more than a month in advance by compiling to-do lists and coordinating with various shops to ensure the buildings will not house work during the shutdown period.

“Whenever we are planning for shutdown, DPW and DEQ work together,” said Mark Johnson, equipment supply division chief for DEQ. “It’s a cooperative effort in planning.”

That cooperative effort lasts all year long. Every week, DPW holds maintenance meetings and a representative from DEQ is always present. Those meetings, as shutdown draws near, help the organizations set repair priorities.

And the assistance they provide each other extends beyond the conference room. DEQ often relies on DPW’s shops for repair assistance.

“There will always be things planned that we need DPW’s assistance with, especially the machining and weld shops,” said Johnson.

DPW and DEQ employees are always ready and willing to do whatever it takes to “keep it running,” as DPW’s motto says, and are grateful for the opportunity to do so without affecting production.

“We would never shut production down. That’s not something we do. But, if we don’t do the preventative maintenance, they might have an emergency shutdown they didn’t anticipate.” said Gaines. “Our people really care about the depot and this is more than just a job for them. They do whatever it takes.”

Two areas in particular receive attention each shutdown, the areas where blast media is used and the cranes in the industrial area, particularly ones in the Combat Vehicle Repair Facility.

“That building has over 10,000 feet of crane rail. Our employees check every bolt and torque each of them to ensure they are tight,” said Johnson.

In addition to maintenance, shutdown is an ideal time for inventory. During this month’s shutdown, the Directorate of Material Management did just that.

“We conducted a wall-to-wall inventory of the automated storage and retrieval system facilities,” said Steve McCarley, director of material management.

McCarley said 48 employees performed inventory on first shift and 38 on second shift. These individuals were from the directorates of material management, production, production management, information management and engineering and quality as well as some contractors and members of DLA Land at Anniston.

Social Sharing