FORT BENNING, Ga. - The post is making a pitch to ramp up its renewable energy use with the purchase of two small wind turbines installed Monday outside a Warrior Transition Battalion barracks.

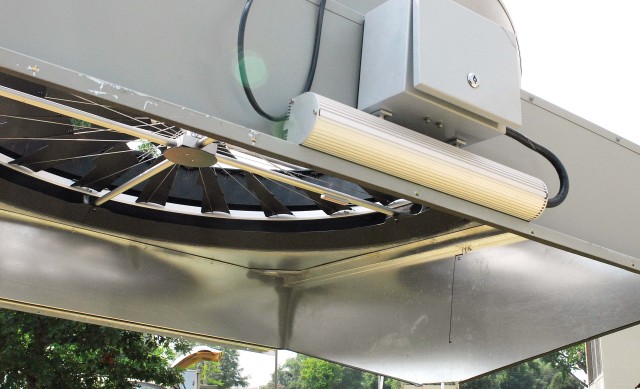

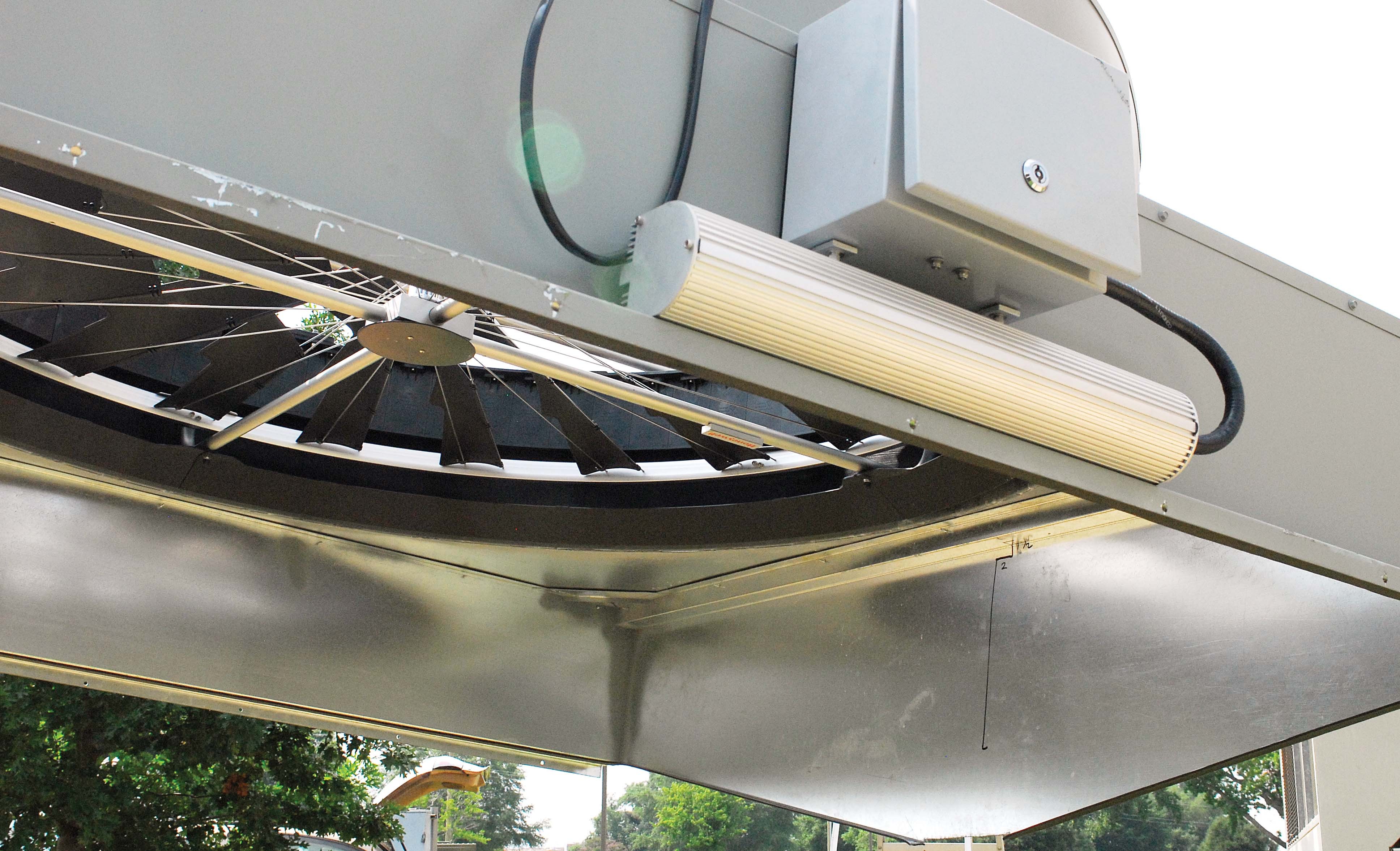

Fort Benning Energy Manager Vernon Duck said they’re designed to capture updraft off the air-conditioning unit’s four condenser fans and convert it into reusable energy. The twin generators, developed by a Michigan-based company called WindTronics, sit atop manifolds on the building’s air-cooled chiller. If proven successful, the Blade Tip Power System could be expanded across the installation in the future.

“This is innovative. It’s really a slick new technology,” he said. “We’re going to look into these turbines and see what we get out of them. We’re aggressively seeking any alternatives that are economically viable to help us meet our renewable energy goals.”

The Energy Policy Act of 2005 requires all government installations to purchase and consume at least 3 percent of their electrical consumption from renewable resources. Duck said the standard rose to 5 percent last year and will reach 7.5 percent in 2013.

He said Fort Benning isn’t meeting the mandate now but could get to 2 percent with various projects under way, including the wind turbines and a waste methane gas effort at a landfill.

“Green” energy comes with a high price tag, Duck said. For instance, a package offered by Georgia Power would cost the installation about $800,000 a year. He said the Army believes it can spend less by generating renewable alternatives from within. But this post has limited amounts of wind and sun.

On average, Fort Benning receives just 4.9 solar hours a day, he said. The Southeast also falls in Wind Class Area I, meaning there’s normally less than 5 meters a second at 30 feet.

Friction and resistance, however, are low on the 6-foot-diameter turbines from WindTronics, officials said. The wheels begin spinning at 2 mph winds.

“We call it exhaust recovery application,” said Sarah Jenan, the company’s vice president of technical commercialization. “It can offset utility consumption. You’re trying to recover some of the energy that’s being wasted through the airstream. It channels that air up through the turbine and generates energy from that.”

Her father, Imad Mahawili, who has a Ph.D. in chemical engineering, invented the device in 2009. Jenan said WindTronics markets its wind turbines to the public, but this marks the company’s first venture with a military installation.

Duck said any energy savings from the WTB project will be confined to that barracks, where officials hope to slow down the building’s watt meter. The spinning turbine will create vertical airflow and pull measuring 25-30 mph and reduce the condenser fan workload on the chiller.

“This air would normally be exhausted out into the atmosphere,” he said.

Each wind turbine cost about $6,500, plus engineering and installation costs, Duck said. The Directorate of Public Works will conduct a life-cycle cost analysis in the next year to determine whether the plan proceeds.

“You have to take some risk when you’re trying a new technology out,” he said. “We’re willing to spend the money to test and evaluate it. We think we’ll get enough savings from it to pay for itself.”

DPW estimates the wind turbines will yield 3 kilowatts an hour of renewable energy. Duck said more than 18,300 kilowatts could be gained, if the air-conditioner is used for 70 percent of the year.

Based on testing, the wind turbines could reclaim up to 15 percent of the power consumed by the chiller, which adds up over time, Jenan said.

Duck said there are roughly 1,700 buildings on Fort Benning. If the technology was applied to 1,000 structures, it could hypothetically generate up to 3 megawatts an hour in renewable energy.

“Last year, we spent $36 million on gas and electricity. With all the new facilities we have, that’ll probably go to $40 million this year,” he said. “We consume a lot on this installation. Any energy we can produce here ourselves is very beneficial.”

Social Sharing