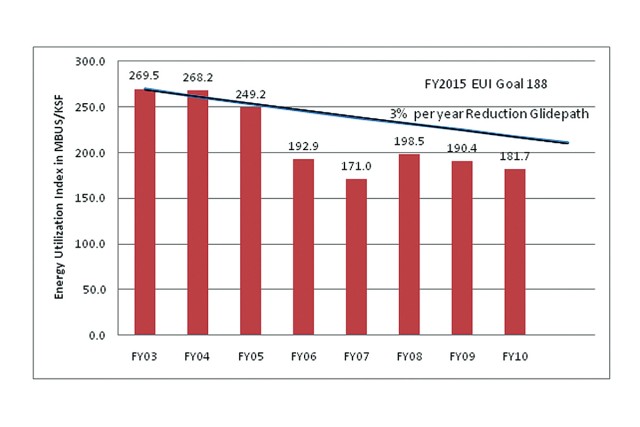

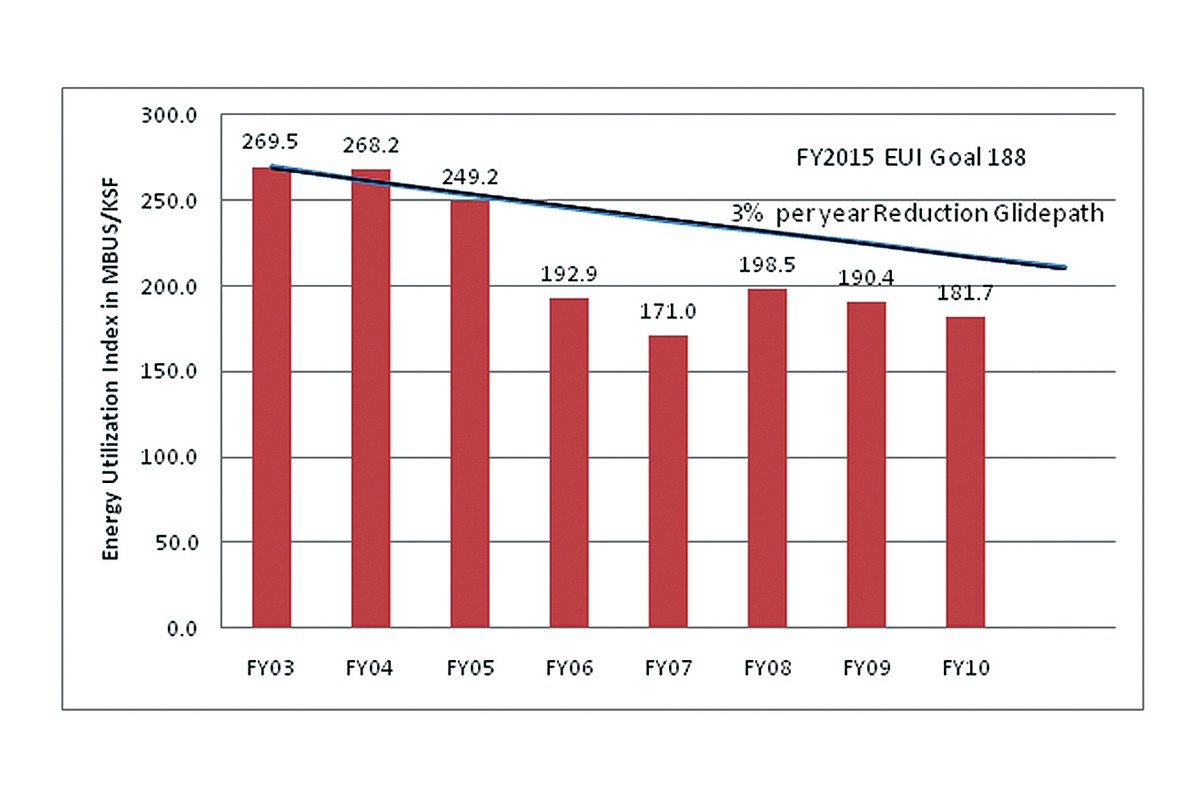

PICATINNY ARSENAL, N.J. - The energy management team at Picatinny Arsenal recently surpassed the Army-wide goal to reduce energy consumption by 30 percent five years ahead of schedule.

The Army's time table for all installations to achieve this goal is slated for fiscal year 2015. Picatinny met the goal at the close of fiscal year 2010.

Furthermore, Picatinny has also reduced water consumption by 200,000 gallons per day for potable water that comes from the underground aquifer, despite a 26 percent population increase at the arsenal.

As a top leader in energy conservation in the Army, Picatinny's energy and water savings are the result of nearly a decade of planning, assessing, constructing and coordinating to slash the installation's energy and water consumption.

"Although the individual energy and water saving measures taken at Picatinny stand alone as good projects, it is the holistic integration of some measures that magnifies the effect," said Nicholas Stecky, Picatinny resource efficiency manager. "We weren't only looking at energy. We integrated our plan to also include water, safety and environmental concerns, as well as cost savings."

The first big step in reducing Picatinny's energy consumption came with a major upgrade to the post's central heating plant, which produced both electricity and steam to serve the high-energy demands related to munitions production at the arsenal through the 1940's to 1960's.

With Picatinny's changing mission from manufacturing to research and development after the Vietnam War, the installation underwent a $36.1 million steam decentralization project from 2003 to 2006.

In total, the steam decentralization project had a price tag of $36.1 million. But the annual energy savings resulted in $2.5 million and 272,375 MBTUs (one million British Thermal Units), plus an additional $2.8 million in non-energy annual savings. By factoring in the project's life cycle of 25 years, Picatinny calculates a payback time of about seven years with a total net savings of $96.6 million.

The success of this effort was the result of close teamwork, planning and execution between Picatinny Arsenal, Chevron Energy Services, the Energy Savings Performance Contractor, and Veolia Water Inc., the government-owned, contractor-operated water plant operator.

Following the steam decentralization project, the next step was to incorporate additional energy improvements to develop a holistic, comprehensive plan to address energy, water, safety and environmental concerns. Picatinny officials established the Energy and Water Team, comprised of Picatinny civilians, contractors and industry representatives, to modify the existing energy conservation contract.

"By modifying the existing contract instead of creating a new one, the team saved two years in delivery time, while also achieving savings two years earlier," Stecky said. "We increased guaranteed savings by $1 million annually and installed an additional $10 million in energy-related capital improvements."

Throughout fiscal years 2008 and 2009, Picatinny completed several more energy efficient projects:

- Converted two buildings from oil and propane to natural gas;

- Installed new boilers for a group of buildings called the "1400 Enclosure Area" to eliminate steam distribution lines, which eliminated about 5,000 feet of steam line and associated losses;

- Rebuilt service water pump station, installed high-efficiency pump motors with variable speed drives and high-efficiency filtration for sediment control;

- Expanded a post-wide energy management system to include heating and air conditioning controls for 13 buildings;

- Upgraded steam system by installing boiler stack economizers and boiler wastewater, called "blowdown," heat recovery units at the two boiler plants; and

- Installed a filtration system and converted the two largest boiler plants from potable water use to service water.

"This holistic approach reduces energy consumption, green house gases, potable water use and chemical treatment use," he added. "It also saves money, avoids potable water plant expansion, preserves the long-term sustainability of the potable water well aquifer and reduces the sewage flow rate by 140,000 gallons per day." (The remaining 60,000 gallons is used as steam).

To date, Picatinny has received several prestigious recognitions for its holistic conservation, including the 2010 Federal Energy Management Program award and the 2010 Secretary of the Army Energy and Water Management Award.

_________________________________________________________________________________

About Us: Picatinny Arsenal is the Joint Center of Excellence for Armaments and Munitions, providing products and services to all branches of the U.S. military. Nestled in the northern New Jersey skylands, the team of 5,000-strong specializes in the research, development, acquisition and life cycle management of advanced conventional weapon systems and leap-ahead ammunition. Learn more at www.pica.army.mil

Social Sharing