PICATINNY ARSENAL, N.J. -- Perhaps no subject is closer to the hearts of Soldiers than their weapons and ammunition. For decades, this intense interest in "guns and ammo" has sparked sharp debate over the best weapons and ammunition on the battlefield, a debate that continues to the present day.

Today, <a href="https://www.pica.army.mil/peoammo/Home.aspx" target="_blank">Program Executive Office Ammunition</a> (PEO Ammo) at <a href="http://www.pica.army.mil/PicatinnyPublic/index.asp" target="_blank">Picatinny Arsenal, N.J.,</a> manages DOD's conventional ammunition programs for all of the military services. PEO Ammo has life-cycle responsibility for the many different types of ammunition used by the joint warfighter, including general-purpose small-arms ammunition.

In 1960, when Army Research and Development Newsmagazine-the forerunner of <a href="http://asc.army.mil/altmag/default.cfm" target="_blank">Army AL&T Magazine</a> -first appeared in print, a major controA,A!versy was raging over the relative merits of the then-standard 7.62mm round and a lighter, higher-velocity 5.56mm alternative. The Army adopted the 5.56mm M16 rifle in 1967; it fired the M193, the first 5.56mm round.

Nevertheless, the controversy continued over which caliber was better-5.56mm vs. 7.62mm-as the magazine noted through the years. In 1982, a review by Army Research, Development, and Acquisition Magazine (as it was then called) of small-arms ammunition development praised the lighter weight and lesser recoil achieved with the smaller round, yet observed that, "One of the inferiorities is, however, its penetration capability."

In 1982, the Army adopted the 5.56mm M855 round to replace the M193 in an effort to achieve better performance at longer ranges with the M249 Squad Automatic Weapon (SAW). A steel penetrator in the front end of the M855 provides increased hard-target performance.

Development of the M16A2 rifle, which matched the twist of the M249 SAW, also allowed use of the heavier M855 round. The M193 is still produced today, largely for foreign military sales.

From 2003 to 2006, the Army conducted a study of available bullets, commercial and military, and found none that provided improved perforA,A!mance over the M855 against the target sets required of a general-purpose round.

Ensuring Consistency and Environmental Responsibility

In post-combat surveys and field reports from Iraq and Afghanistan, most Soldiers have indicated that the round works fine, delivering the desired effects against threat targets. But some Soldiers have reported that the round did not perform consistently, causing concern in the ammunition community.

In parallel, mounting environmental concerns drove the Army to consider replacing environmentally unfriendly materials such as lead. The Army's ammunition community, led by PEO Ammo, saw an opportunity to address the two concerns associated with the M855 round-lead and consistency.

The Army's solution is the new M855A1 Enhanced Performance Round (EPR). This round offers better performance than the M855 against all targets likely to be engaged with small arms. This is quite a feat, considering the long-standing solid performance of the M855.

While it's true that a number of bullets (such as armor-piercing bullets) can penetrate hard targets well, they don't provide the needed effects against soft targets. Conversely, some bullets (such as hunting rounds, hollow-point, and other bullets) work well against soft targets but can't penetrate harder barriers. Nor do hollow points meet the Army's requirement to adhere to the Law of War, defined as "[t]hat part of international law that regulates the conduct of armed hostilities. It is often called the 'law of armed conflict' " (DoD Directive 2311.01E, DoD Law of War Program). Even today, we have found no other round-other than the new EPR-that can outperform the M855 as a capable, general-purpose round.

Why the M855A1 Excels

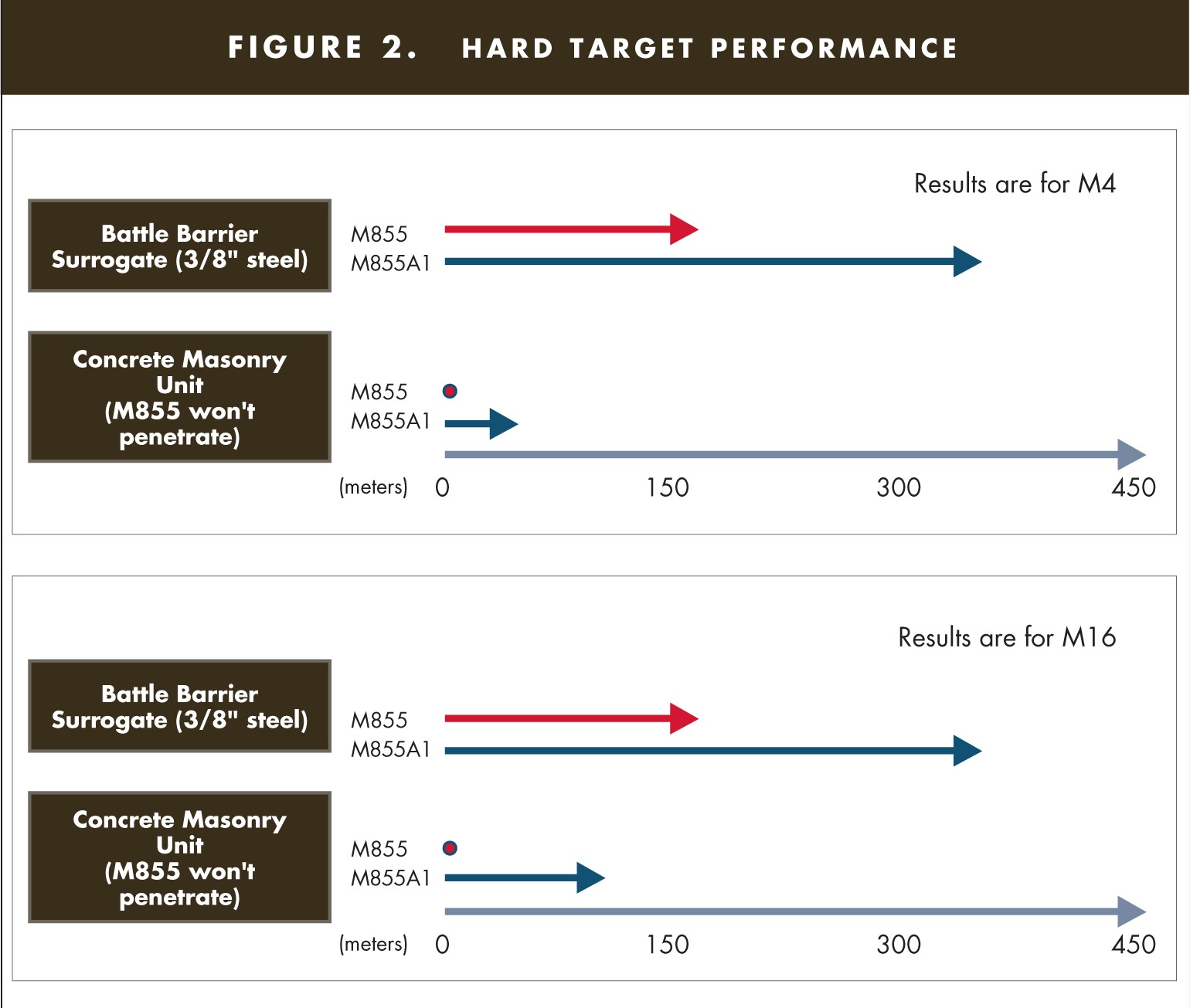

So what makes the EPR so good' It uses the same components as the M855-a jacket, a penetrator, and a metal slug. But the new round contains some subtle changes (see Figure 1). The copper cup, from which the jacket is formed, is reverse-drawn, the opposite of how the M855 jacket is drawn. The hardened steel penetrator is almost twice as heavy as the one used in the M855 and is fully exposed instead of hiding beneath the softer copper jacket.

The slug is made of copper, making the projectile nonhazardous to the environment while delivering needed performance. Since the EPR is similar to the M855, the Army can use the same manufacturA,A!ing equipment now used for the M855, providing additional savings and large-scale manufacturing capability. Once the M855A1 replaces the leaded M855, it will reduce the amount of lead in production by approximately 2,000 metric tons yearly, based on the amount now used to make the M855.

There are three main areas in which the new round excels: soft-target consistency, hard-target penetration, and the extended range at which it maintains these performance improvements.

This is not to imply that the EPR increases the maximum effective range of the M4 or M16. Its trajectory matches the M855's, which aids in training, lessens the need to re-zero the weapon, and allows it to link to the current tracer round (the M856) for eventual use in the M249 SAW. So while the maximum effective range does not increase, effectiveness at range does, meaning the round greatly extends the range of desired effects along its trajectory.

The Army tackled the consistency issue by focusing on the yaw of a projectile and how differences in yaw can influence results when striking soft targets. The M855 round, similar to the Army's M80 (7.62mm ball round), is a "yaw-dependent" bullet. As any bullet travels along its trajectory, it "wobbles" in both pitch and yaw, causing the projectile to strike its target at different attitudes with virtually every shot.

For a yaw-dependent bullet such as the M855 or M80, this results in varying performance, depending upon where in the yaw/pitch cycle the bullet strikes its target. For example, at a high angle of yaw, the M855 performs very well, transferring its energy to the target in short order. At a low angle of yaw, however, the bullet reacts more slowly, causing the inconsistent effects observed in the field.

The M855A1 is not yaw-dependent. Like any other bullet, it "wobbles" along its trajectory. However, the EPR provides the same effects when striking its target, regardless of the angle of yaw. This means the EPR provides the same desired effects every time, whether in close combat situations or longer engagements. In fact, the U.S. Army Research Laboratory (ARL) verified through live-fire tests against soft targets that, on average, the M855A1 surpassed the M80 7.62mm round. The 7.62mm, although a larger caliber, suffers from the same consistency issue as the M855, but to a higher degree.

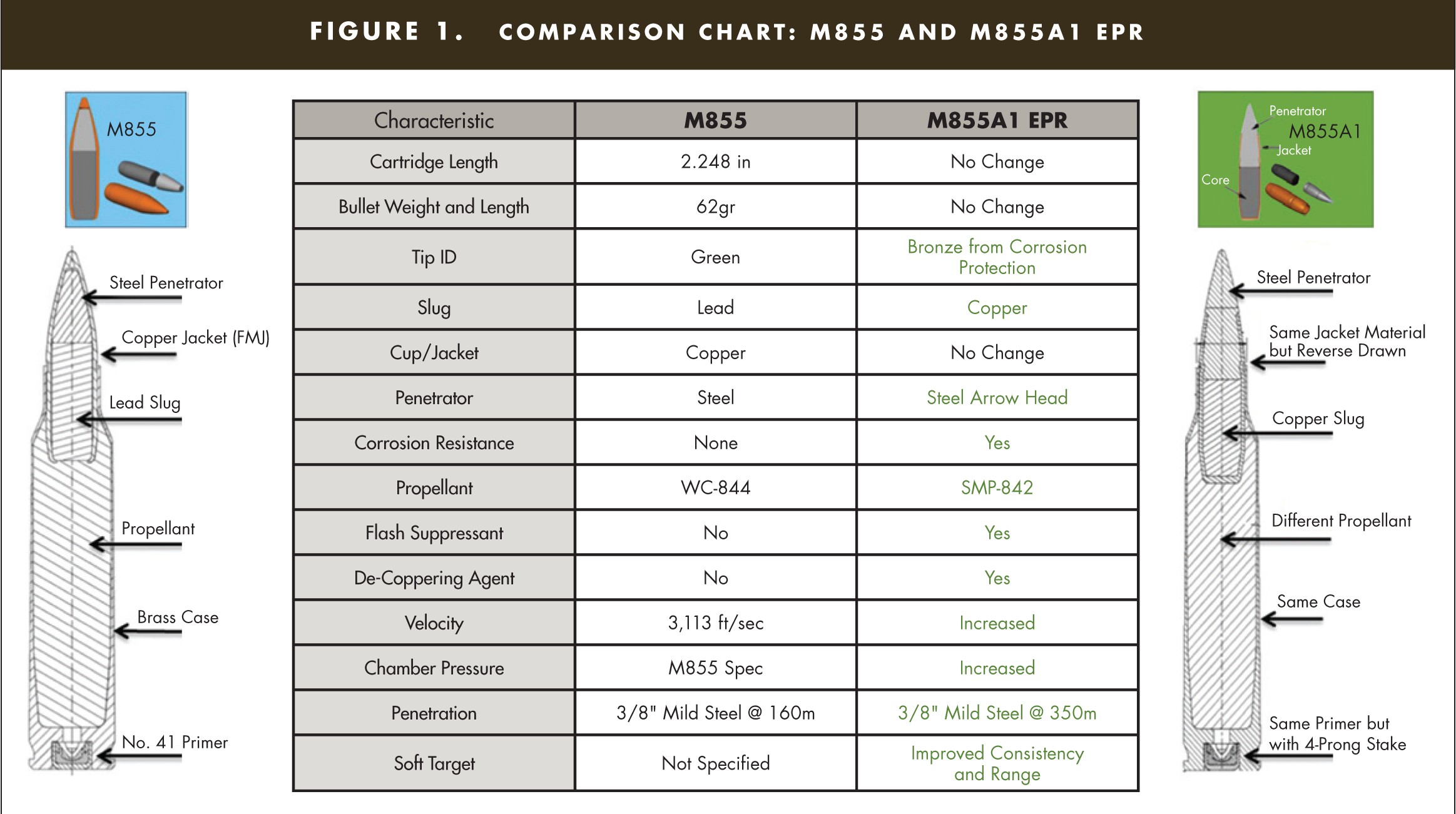

Hard-target performance is a second area where the EPR really shines (see Figure 2). The exposed, heavier, and sharper penetrator, along with a higher velocity, allows Soldiers to penetrate tougher battlefield barriers than is possible with the current M855. Although it's not an armor-piercing round, the EPR can penetrate 3/8 inch-thick mild steel at distances approaching 400 meters (based on the range at which 50 percent of the rounds can pass through the barrier). The M855 only penetrates this material out to approximately 160 meters.

Not only is this performance much better than the M855's with its smaller steel penetrator, it is vastly better than the M80 7.62mm round.

Additionally, the EPR can penetrate concrete masonry units at ranges out to 80 meters with the M16 and 40 meters with the M4. The M855 can't penetrate this type of battlefield barrier at any range.

Also notable is the EPR's excellent performance against softer intermediate barriers such as car doors, windshields, or Kevlar fabric. The thinner metal found on car doors poses no problem. When engaging targets behind windshields with the EPR, ARL has shown an increase in the probability of hitting the occupant, due to both the steel penetrator and the copper slug remaining intact through the glass. Furthermore, ARL tested the round against 24 layers of Kevlar fabric out to 1,000 meters, but discontinued the test as the Kevlar showed no sign of being able to stop the EPR. The EPR also penetrates some lesser-quality body armors designed to stop 7.62mm ball rounds.

Another benefit Soldiers will see from the new round is its effectiveness when engaging soft targets at longer ranges.

As a small-caliber projectile's velocity decreases, it eventually will reach a point at which it can no longer transfer most of its energy to its target. Below this velocity, which equates to range, the round is more likely to pass through its target with little effect. The M855A1 can maintain consistent, desired effects at a much lower velocity, resulting in excellent effectiveness at far greater ranges along its trajectory.

In addition to the above-mentioned performance improvements, the EPR is more accurate than the M855. Accuracy testing during production lot acceptance has shown that, on average, 95 percent of the rounds will hit within an 8 x 8-inch target at 600 meters. It also uses a flash-reduced propellant optimized for the M4's shorter barrel.

The good news is that all of these performance improvements come with no weight increase to the Soldier.

Soldiers Are the Focus

Soldiers will surely discuss the M855A1 EPR during their ritual debates on guns and ammo. The new M855A1 will greatly increase Soldier performance on the battlefield, but inevitably, Soldiers will have the final vote as they must maintain their weapon systems, train, aim, and engage their targets. As always, good marksmanship skills are critical for success in small-arms engagements. No matter how good the bullet, it can't do its job if it doesn't hit the target.

During the past 50 years, 5.56mm general-purpose ammunition has evolved to a level of performance that addresses all of the major warfighting needs of our services. The M855A1 EPR is a significantly improved 5.56mm round that provides excellent soft target consistency and vastly better hard target performance, and increases our Soldiers' effectiveness at extended ranges with better accuracy-all without increasing their load.

The M855A1 represents the most significant performance leap in small-arms ammunition in decades. Our Soldiers deserve the best, and with the M855A1 EPR, they get it.

LTC JEFFREY K. WOODS is the Product Manager for Small-Caliber Ammunition in the Office of the Project Manager Maneuver Ammunition Systems, PEO Ammo. He holds a B.S. in business administration from the University of Texas and an M.S. in operations research from the Florida Institute of Technology. Woods is also a graduate of the U.S. Army Command and General Staff College and Defense Systems Management College, and is a U.S. Army Acquisition Corps member.

Social Sharing