TOBYHANNA ARMY DEPOT, PA. - Tobyhanna electronics mechanics built a prototype test set to support the Air Force's latest identify friend or foe (IFF) equipment.

Transponder Branch employees are gearing up to repair hundreds of AN/APX-124(C) Digital Transponders being installed in active duty and National Guard F-16 Fighting Falcon aircraft. New test equipment and cables fabricated here will support a new Inter Service Depot Agreement between Tobyhanna and the Air Force.

A transponder is an electrical device designed to receive a specific signal and automatically transmit a specific reply. When used in aircraft, transponders help distinguish friendly forces from the enemy.

"The cost center's extensive experience on the AN/APX-118 and AN/APX-123 made Tobyhanna the depot repair facility for this equipment," said John Manning, branch chief. "The branch will be responsible for repairing hundreds of units installed in the Block 40/42 version of the fighter aircraft." Manning works in the Command, Control and Computer/Avionics Directorate's Avionics Division.

According to Manning, the new workload is valued at more than $20 million and having Tobyhanna perform the repairs will save the government more than $400,000 over the life of the program.

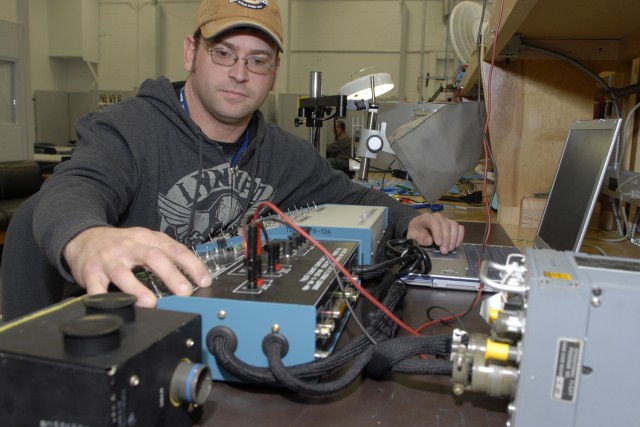

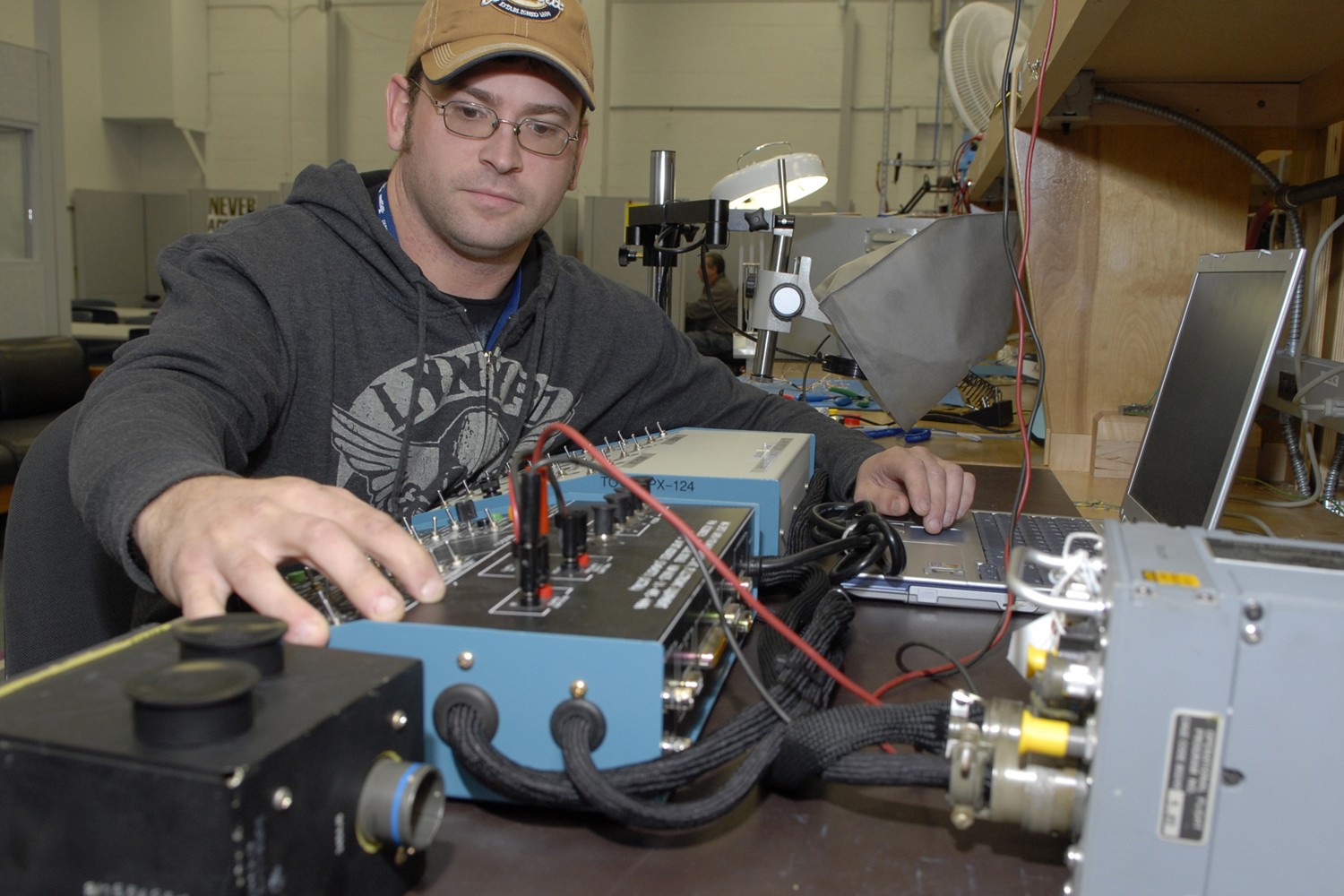

The new test set works with legacy equipment to simulate how the transponder works inside the cockpit of an aircraft. Electronics Mechanics Fred Granoski and Kevin Jones teamed up to develop an interface box and the cabling necessary to test the AN/APX-124(C). As a result, their design allows older model test equipment to work on new technology.

"We reverse engineered the AN/APX-124 inputs and outputs and created an interface box to control the signals of the test parameters" said Granoski. "We were tasked to develop capability to test and repair, thus insuring that future workload of the AN/APX-124 is met."

"The transponder thinks it's in the aircraft when hooked up to the test set," said John Kostiak, electronics mechanic. "Fred and Kevin took existing information to create an interface box that adapts an older control panel to the transponder."

He explained that the control panel is currently used to test the AN/APX-118 and the interface helps it communicate with the newer equipment.

There are more than 20 employees who test and repair several types of transponders supporting Navy, Army and Air Force programs. Thousands pass through the shop annually.

"Everyone has done an outstanding job getting ready for this program," Manning said. "We're excited to be working on this brand new technology."

Tobyhanna Army Depot is the Defense Department's largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network. Tobyhanna's missions support all branches of the Armed Forces.

About 5,600 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army CECOM Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing