TOBYHANNAY ARMY DEPOT, Pa. (Army News Service, June 20, 2007) Aca,!" Tobyhanna employees work around the clock to repair equipment damaged in Southwest Asia and ensure servicemembers are prepared to carry out their mission in the war on terrorism.

Depot technicians maintain thousands of systems and equipment that fit into one of three programs depending on the type of work needed. Recapitalization is the highest level of repair, followed by overhaul and reset.

Reset, both at the depot and in the field, returns systems and equipment to pre-deployment readiness as quickly as possible with minimal repair.

Aca,!A"The item will operate at full-mission capability, but with few cosmetic improvements,Aca,!A? said Pat Esposito, production management director. Aca,!A"We work with each customer to ensure we satisfy their work requirements.

Aca,!A"Tobyhanna hasnAca,!a,,ct missed a fielding for the reset program to date,Aca,!A? he said. Aca,!A"Personnel are getting the metal out the door by working three shifts, seven days a week, with overtime. Morale is high and each person is proud to support the warfighter.Aca,!A?

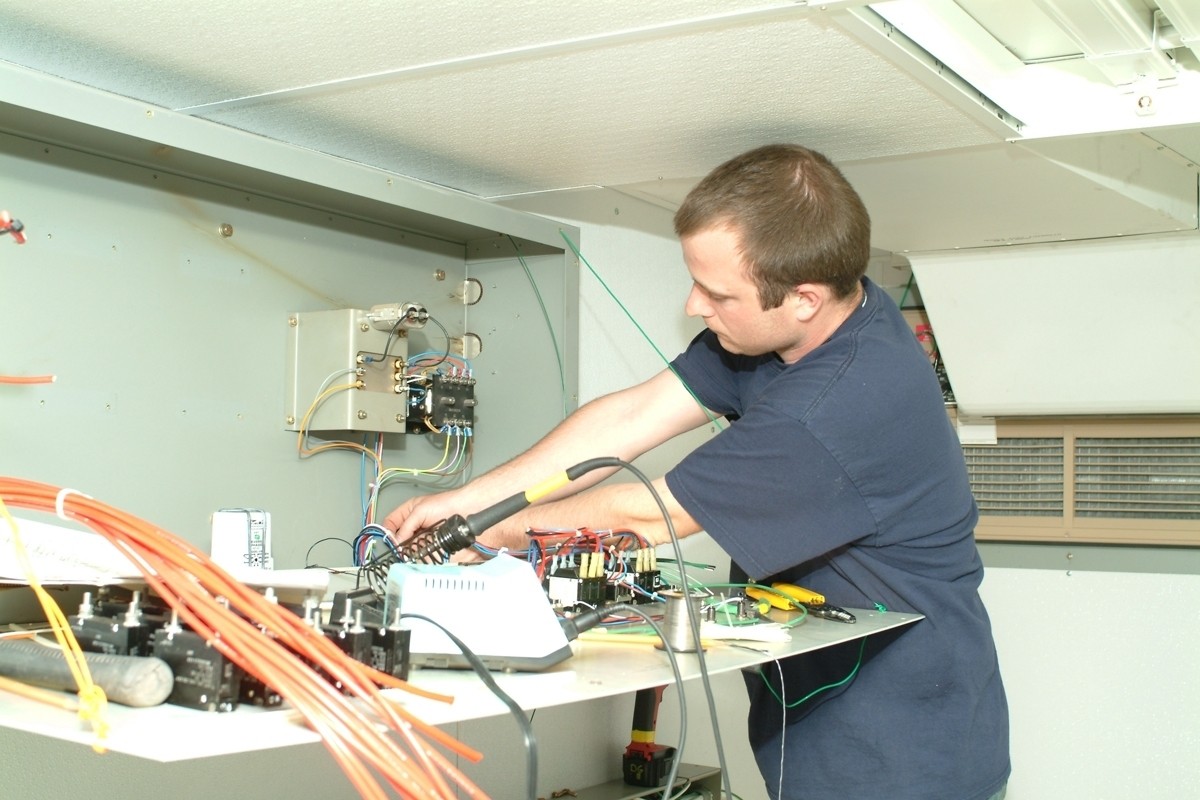

Overhaul has two main components: electrical and mechanical. Electrical repairs include diagnosing equipment failures and replacing defective components, while mechanical repairs involve full restoration to like-new condition.

According to Mr. Esposito, overhaul often requires replacement parts and can include sandblasting, cleaning, priming and repainting equipment.

Recap repairs items to the full overhaul standard, and includes installation of new components with improved performance.

Aca,!A"The items are returned in brand-new condition,Aca,!A? said Ron Neher, commodity workload analysis branch chief. Aca,!A"When it goes out the door, itAca,!a,,cs like having a car with zero miles.Aca,!A?

Program goals include extending the service life of equipment or systems, reducing operating and support costs, and improving reliability, safety and maintainability.

Aca,!A"TobyhannaAca,!a,,cs work effort includes a higher level of testing, more mandatory-part replacements and the addition of Sentinel radar components,Aca,!A? said Robert Katulka, intelligence, surveillance and reconnaissance director. Aca,!A"A recapitalized Firefinder will have an extended-life cycle, improved performance and reduced operating cost. It will be better than new.Aca,!A?

Tobyhanna Army Depot employs approximately 4,400 personnel and is the Department of DefenseAca,!a,,cs largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components. It is part of the U.S. Army Communications-Electronics Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the commandAca,!a,,cs mission is to research, develop, acquire, field and sustain communications, command, control, computer, intelligence, electronic warfare and sensors capabilities for the armed forces.

(Jacqueline Boucher is a public affairs officer at Tobyhanna Army Depot.)

Social Sharing