TOBYHANNA ARMY DEPOT, PA. - Multi-Threat Systems Branch employees have set a new record for the overhaul of a critical Air Force asset.

The first, on-time delivery of a like new AN/MST-T1(a) Multiple Threat Emitter Simulator (MUTES) was the result of a five-year process improvement campaign to reduce the Repair Cycle Time (RCT) to just over 500 days - saving time and money.

Members of the Range Threat Systems Division have refined processes, developed new test procedures and documented work standards that have cut labor and material costs by nearly half. In the past, the overhaul of one system could take more than 1,400 days.

"We're capturing the workload with processes to maintain the high standard of performance into the future," said Joe Scheff, branch chief. "So far, our current workload is on track to ship on time."

Scheff remarked that the funding for the MUTES overhaul program is set by the customer early in the process. By instituting continuous improvements the branch has become more efficient and cost effective, he added.

"It felt good to ship the system out on time," said Bill Dierolf, electronics mechanic. "It was rewarding to see everything finally come together to meet the customer's needs." Dierolf helped with the build-up and integration. He also worked alongside the system integrator, tracking the hundreds of items undergoing various stages of repair in shops throughout the depot.

"I'm so proud of what the MUTES team has been able to accomplish so far," Scheff said. "There are more ideas in the pipeline that should help cut additional time off the RCT in the future." The branch is part of the Intelligence, Surveillance and Reconnaissance Directorate and employs more than 30 personnel.

John Ondrusek said improvements were made every time a system came in for overhaul. "This accomplishment was made possible through the hard work of branch employees and others throughout the depot.

Members of the MUTES transmitter shop and Jeff Kramer contributed greatly to this effort." Ondrusek is a system integrator.

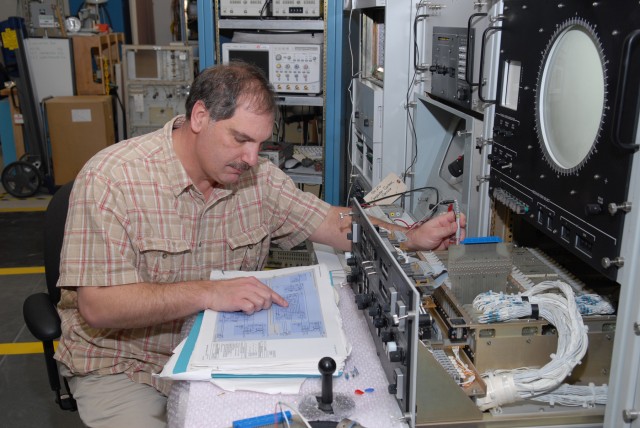

During overhaul, the systems are completely dismantled; the individual pieces evaluated for repair or replacement, and inventoried. Employees overhaul computer systems, track drawers, planed position indicators and test equipment racks. The system is also integrated, tested and aligned for optimum performance.

The MUTES is an Identify Friend or Foe (IFF) tracking and training simulator that provides realistic threat signals for pilots and aircrews. The system can replicate threats such as surface-to-air missiles, early warning radar systems, anti-aircraft artillery and airborne intercept systems. Each system contains 19 threat transmitters.

"Scheff and his MUTES crew, along with all the other supporting branches and divisions, did a magnificent job on beating the customer's expectation in schedule and quality," said Thomas Bright, division chief. He noted that MUTES SN 007 was scheduled for completion on Dec. 23, which would have been 13 days ahead of schedule. Had it not been for some unexpected electronic challenges with two of the transmitters, the asset would have shipped to the Distribution Depot Tobyhanna Pennsylvania (DDTP) prior to Christmas.

"With tremendous effort and commitment, Scheff and the members of his crew gave up leave over the holidays to solve each challenge in order to beat the deadline by one day--a first ever," Bright said. "From mid-November, when the team could taste mission success, there was no question that they would pull out all stops to complete the task on time."

The new processes have also earned Tobyhanna accolades from customers. The last four systems have received 100 percent satisfaction reports.

"The crew from Tobyhanna was exceptional--They were punctual, professional and knowledgeable in all aspects of their job," said Jeromy Williams, Kansas Air National Guard. In addition, an employee at Shaw Air Force Base, S.C., said, "We were very pleased with [Tobyhanna's] service and assistance. The dedication of the team was great."

Tobyhanna Army Depot is the Defense Department's largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network. Tobyhanna's missions support all branches of the Armed Forces.

About 5,600 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army CECOM Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing