KABUL, Afghanistan - Structural engineers with the U.S. Army Corps of Engineers went back to basics to design water towers to be built in Afghanistan, a country where construction methods remain archaic by U.S. standards.

Engineers in Kabul and Mobile, Ala., worked together to design 15-meter-high and 20-meter-high towers fastened entirely with nuts and bolts. "As far as putting it together, you don't realize how difficult it is when you can't weld," said structural engineer Michael Thompson from the Corps' Mobile District.

The challenge for engineers was designing towers that could be built and maintained in remote locations where electricity is unavailable, construction expertise is scarce, and materials are limited by what can be transported by donkeys.

The water towers will be included at dozens of Afghanistan National Police bases being built throughout the arid country. Hundreds of policemen will live and work at each compound, and water stored in the towers will be used for everything from sinks to showers.

Before designing the towers, Corps engineers debated whether the water storage tanks should be located underground or above ground, said Mark Hoague, the chief of engineering at the Corps' northern Afghanistan district headquarters in Kabul.

Underground tanks are easier to build, but require working pumps to provide pressurized water for sinks and showers. In contrast, above-ground tanks are more difficult to build, but can get by with gravity to provide pressurized water.

The deciding factor was the spotty availability of electricity, Hoague said. Corps engineers opted for above-ground tanks. "It was an intelligent debate, but you've got nothing if the water's underground and there's no power. You can have a hand pump, but for 700 people, you can't hand pump water every day," he said.

The engineers reasoned that large quantities of water can be pumped from wells to above-ground tanks in quick bursts, even if electricity is available only intermittently. Once water is stored in above-ground tanks, gravity can be used to dispense it.

The engineers determined they needed two types of towers - 15-meter towers with 9,000-gallon tanks, and 20-meter towers with 7,000-gallon tanks. But the engineers knew that traditional U.S. construction techniques would have presented serious obstacles for many Afghan construction contractors.

Dozens of the police stations are accessible only by narrow mountain passes. That ruled out the use of heavy-duty mechanical cranes. The lack of reliable electricity, welding expertise and materials ruled out welding as well. Furthermore, the towers had to withstand Afghanistan's seismic activity.

Corps personnel opted for assistance from their colleagues in Mobile after contractors in Afghanistan struggled to produce a reliable design, said Christa Besing, an engineer in Kabul. "Hundreds of design submittals were received and all were rejected due to deficiencies in the seismic analysis and skepticism over the quality of the field welds," she said.

Hoague, Besing and fellow engineer Doug Jamieson outlined the requirements and sketched preliminary concepts. They forwarded the material to Corps colleagues Thompson and Allison Pierce in Alabama to design simple, yet reliable, towers held together with nuts and bolts.

In all, the design process took about six weeks in November and December 2009. The teams in Kabul and Mobile discussed the emerging plans in carefully scheduled conference calls that accommodated the 7A,A1/2-hour time difference between their locations. Initially, they spoke once a week. As the design concepts developed and the sides exchanged plans for review, they talked even more frequently.

Pierce said, "It was just a constant communication with Afghanistan back and forth on different parts of the design, what would work and wouldn't work. We'd try one thing and go back and try another way with something that was available in Afghanistan. It was just constant putting our heads together."

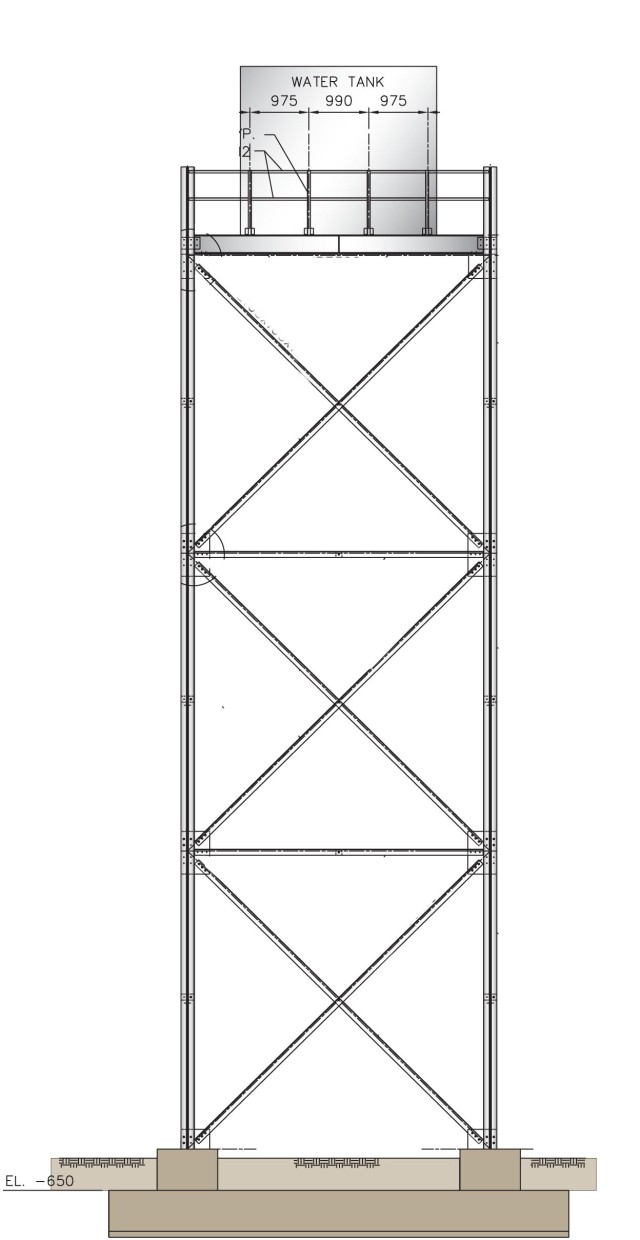

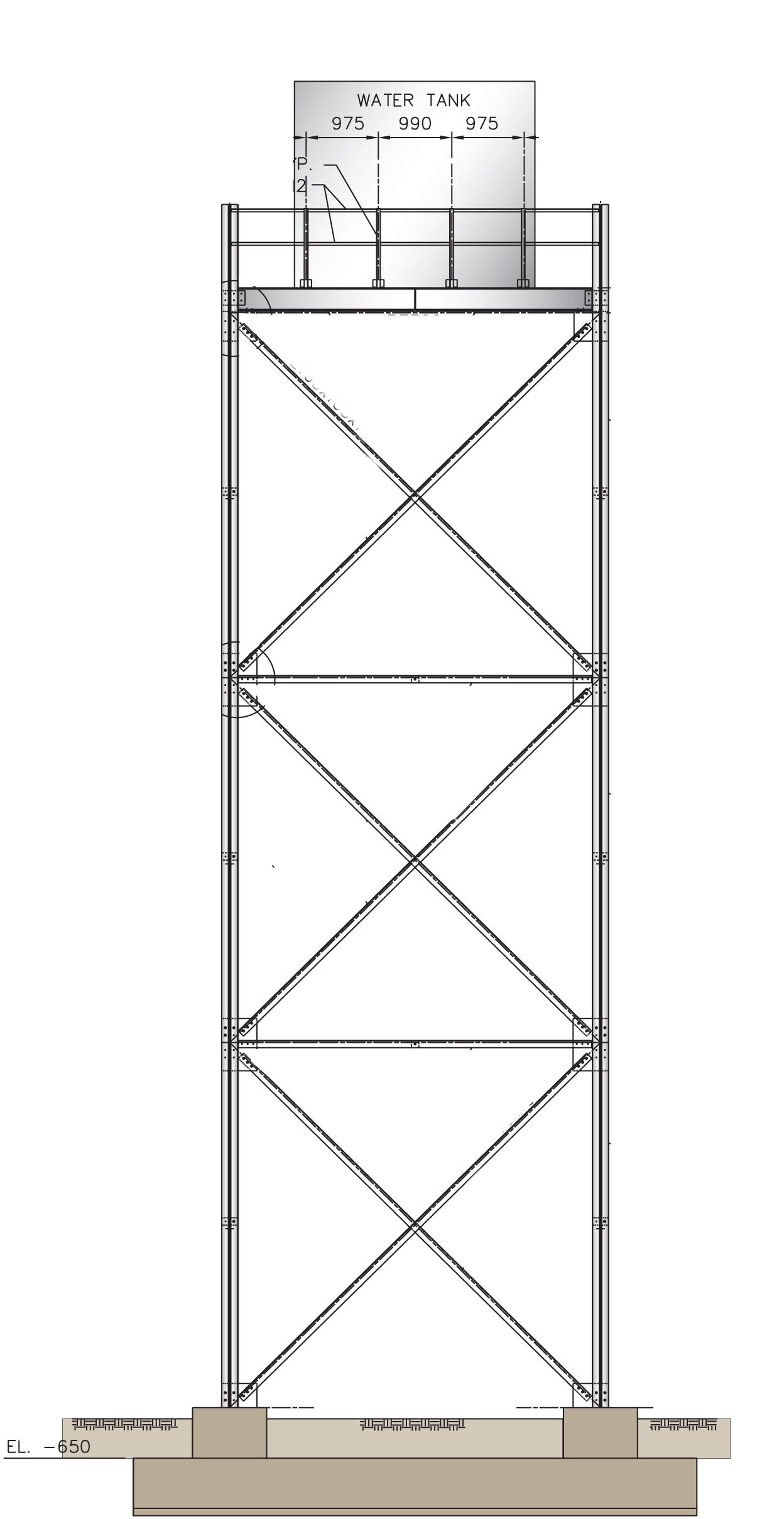

Together, they came up with four-sided towers constructed with 3A,A1/2-inch by 3A,A1/2-inch steel angle bars, affixed to concrete foundations. The design features a series of stacked five-meter sections with cross-bracing on all four sides.

The 15-meter towers use three stacked sections and 1,458 sets of nuts and bolts, while the 20-meter towers require four stacked sections and 1,752 sets of nuts and bolts.

A critical aspect of the design work was determining where each and every hole should be pre-drilled in metal shops before the parts are transported to construction sites. The intent was to eliminate any guesswork by laborers.

"It's all designed. They don't have to do a thing," Hoague said. "Contractors will order tower pieces from steel fabricators, transport them to the job site and use labor to erect both the tower and the tank."

The pre-fabrication work will be critical, said Peter Schei, a structural engineer in Kabul, who reviewed the final design.

"It has to be very accurate," he said while examining a set of plans. "Look at all these details. When they punch that gusset right there, it has to match up perfectly to the mated part. It's like an Erector set."

The most meticulous portion of the tower was a built-in ladder and a metal cage around the ladder, Thompson said. "That was quite a challenge to get it put together and get the bolt holes matched up. Every time you did something, it affected something else. It was like a domino effect," he said.

The engineers also were careful to ensure that the component pieces were light enough that they can be hoisted by two or three men using simple a pulley system. The water tanks will be assembled atop of the towers and fastened with nuts and bolts as well.

The results of the trans-Atlantic collaboration will appear across Afghanistan. The water tower design will be included in all 171 construction packages for Afghan National Police compounds that are expected to be awarded in Fiscal Year 2010. In addition, the towers may be added to as many as four dozen national police stations that were started during Fiscal Year 2009, officials said.

Social Sharing