ANNISTON ARMY DEPOT, Ala. - More than 10,000 items flow into Test, Measurement and Diagnostic Equipment Support Center, Anniston, also known as TMDE, each year from Anniston Army Depot, but those items are mere drops in the bucket compared to the workload of this depot tenant.

"We are one of six places in the world that are certified to calibrate small arms gages," said Frank Howland, electronic measurement equipment mechanic for TMDE.

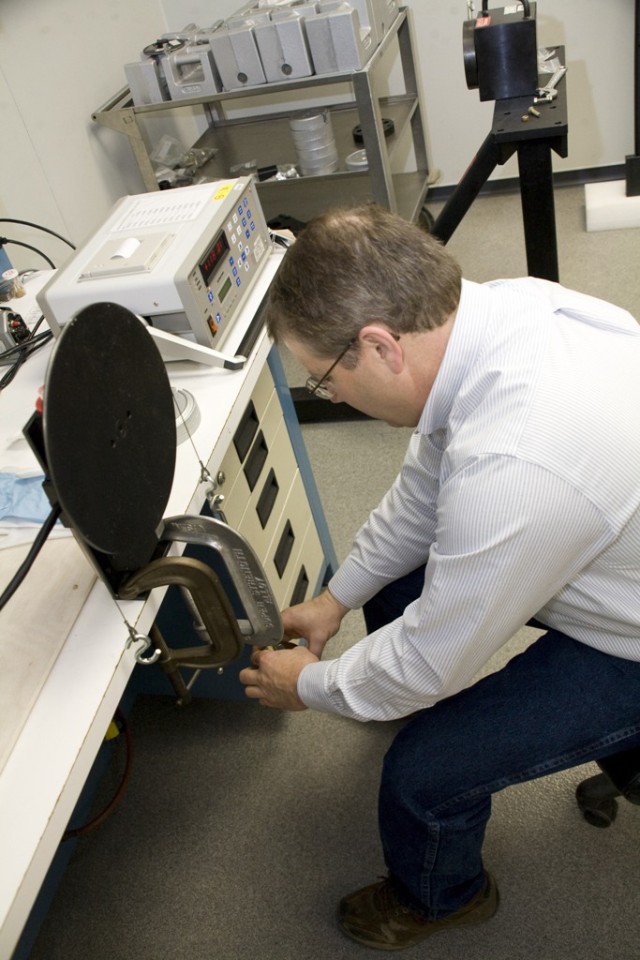

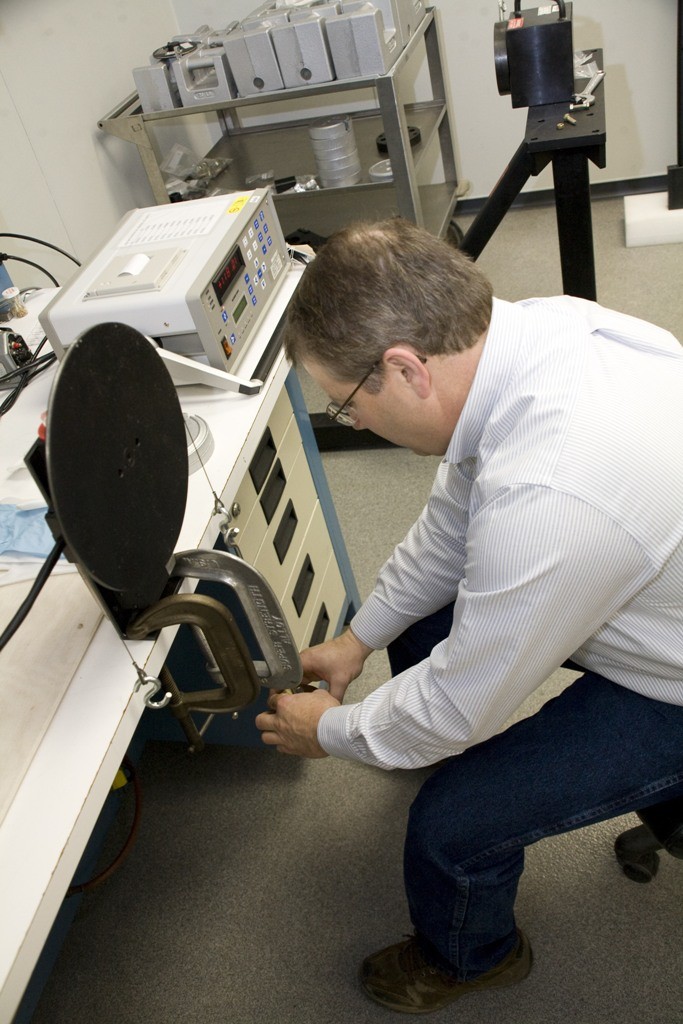

In the small arms gage lab, technicians receive parts for testing and calibration from throughout the eastern United States. Within the temperature and humidity-controlled lab, gages from various types of weapons, including the 50-caliber machine gun, are cleaned and deburred, a process that removes unwanted material. The gages are then checked to ensure they meet requirements for length and width.

"Basically, what we do is test for wear," said Chad Forsyth, lead man in the lab.

They ensure the part is within calibration tolerances by microscopically checking grooves and testing the width of a gage in several places.

On depot, the items touched by TMDE affect the work in nearly every shop.

"Part of our work is done here in the laboratory and we also do on-site work," said Howland. "The lab virtually supports the entire depot. We work with many general-purpose items, such as multi-meters and oscilloscopes."

Each item they calibrate leaves the shop tagged with an identifier that allows it to be tracked. As each piece of equipment returns to the lab, testers are able to determine when the item was last checked as well as the result of that calibration. For many items, this identifier gives the date of calibration as well as the date of the tool's next checkup.

The shop, which has been a depot tenant for more than 20 years, has both a local and global impact. Twice a year, a team travels from Anniston to Honduras for four weeks to provide calibration and testing support.

"Typically, from any one of our regions, we can touch anyone in the world that needs our support," said Joe Klimek, chief of TMDE.

TMDE's parent organization, United States Army Test, Measurement and Diagnostic Equipment Activity, or USATA, has five regions around the world, three of which are located in the United States. TMDE Anniston is located in region two, which covers the southern United States as well as Illinois, Indiana, Iowa, Michigan and Wisconsin.

USATA is responsible not only for testing equipment and tools for the Army, but for maintaining the standards to which the calibration is performed. Therefore, in addition to calibrating gages and other equipment for a number of customers, TMDE boasts the only secondary reference laboratory serving Army installations in Alabama, Mississippi, Louisiana, Florida, Georgia and parts of South Carolina.

With the standards maintained in that library, and equipment sensitive enough to gauge the width and weight of a dollar bill, the employees of TMDE are able to test and calibrate for temperature, humidity, resistance, mass, capacity, force or torque, frequency, attenuation, vibration, RF power, impedance, pressure, inductance, dimensions and voltage.

Social Sharing