So, you’re an executive officer (XO) — now what? Several key responsibilities fall within your scope, whether at the company/troop/battery or battalion/squadron level. This article draws on the invaluable lessons learned from experienced leaders who have served as a troop XO, squadron maintenance officer, and squadron XO in an armored brigade combat team (ABCT). While the article is scaled in dealing with maintenance operations and doesn’t cover the entire scope of an XO’s responsibilities, we hope these insights can serve as a guiding light, helping you to navigate the complexities of your new role. You can directly impact your organization by understanding the processes, your team, and the support you can seek from higher headquarters.

Maintenance Work Order Management

Managing maintenance work orders is essential for keeping your unit’s equipment operational. The process begins with the Global Combat Support System-Army (GCSS-Army), a digital program that tracks all maintenance requests and work orders for a unit’s assets.(1) While navigating GCSS-Army may initially seem overwhelming, it’s important to remember that numerous training resources are available to help you become proficient. You can find multiple online tutorials and unit-level subject matter experts, and we recommend consulting YouTube when in a pinch. Creating a quick reference guide for common work-order statuses can streamline your oversight. Understanding the full life cycle of a work order, from initiation to completion, is more than just tracking deadlines — it’s about identifying bottlenecks, prioritizing repairs, and keeping your commander informed on equipment readiness. As a leader in your organization, it’s essential to know how to utilize GCSS-Army and, at the very least, be able to pull your unit’s equipment status report (ESR).

Navigating the Nuances of the Equipment Status Report

The ESR is vital for assessing your unit’s readiness. Its dense data can be daunting without a clear approach, but mastering it is key to improving your unit’s long-term readiness. Beyond the basic non-mission capable-supply (NMC-S) and non-mission capable-maintenance (NMC-M) designations, the ESR provides a detailed snapshot of equipment availability, maintenance timelines, and part statuses.(2) Each line item includes status codes that indicate specific issues — like “BB” for back-ordered equipment or “B7” for parts with price changes — which require careful interpretation to understand the full scope of delays. Pay close attention to the equipment’s estimated ship date (ESD), as discrepancies between projected and actual timelines can signal deeper systemic issues.

Additionally, cross-reference the ESR with your unit’s maintenance logs to identify recurring problems such as frequent failures in specific systems, enabling you to address root causes and improve long-term readiness. Four reference codes for acquiring parts are 11, 19, 45, and 71. An 11 code means it is still waiting for funding, while 45 denotes that higher has funded the part and you should look for a ship date. A 19 code means that the part has been placed in your unit’s “bin” at the Supply Support Activity (SSA), while 71 indicates that the part is at the SSA but not in the bin. With familiarity, the ESR can transform from a cryptic report into a powerful decision-making and resource-allocation tool.

The ESR is not just another document — it’s a tool that all leaders, especially XOs, should always have in their leader book. At first glance, it may seem intimidating to try and comprehend. However, plenty of cheat sheets are available, and a YouTube series by the U.S. Army Combined Arms Doctrine Directorate breaks down each section.(3) Understanding how to read the ESR is a skill and a necessity for success as an XO. This product is how you inform your higher headquarters and big Army about your organization’s needs. While Excel tools are helpful, leveraging existing systems like GCSS-Army and common operational picture (COP) systems ensure consistency and efficiency — fight off your ESR and ensure that it is accurate and clean.

Figure 1 — Example of a “Cheat Sheet” Equipment Status Report

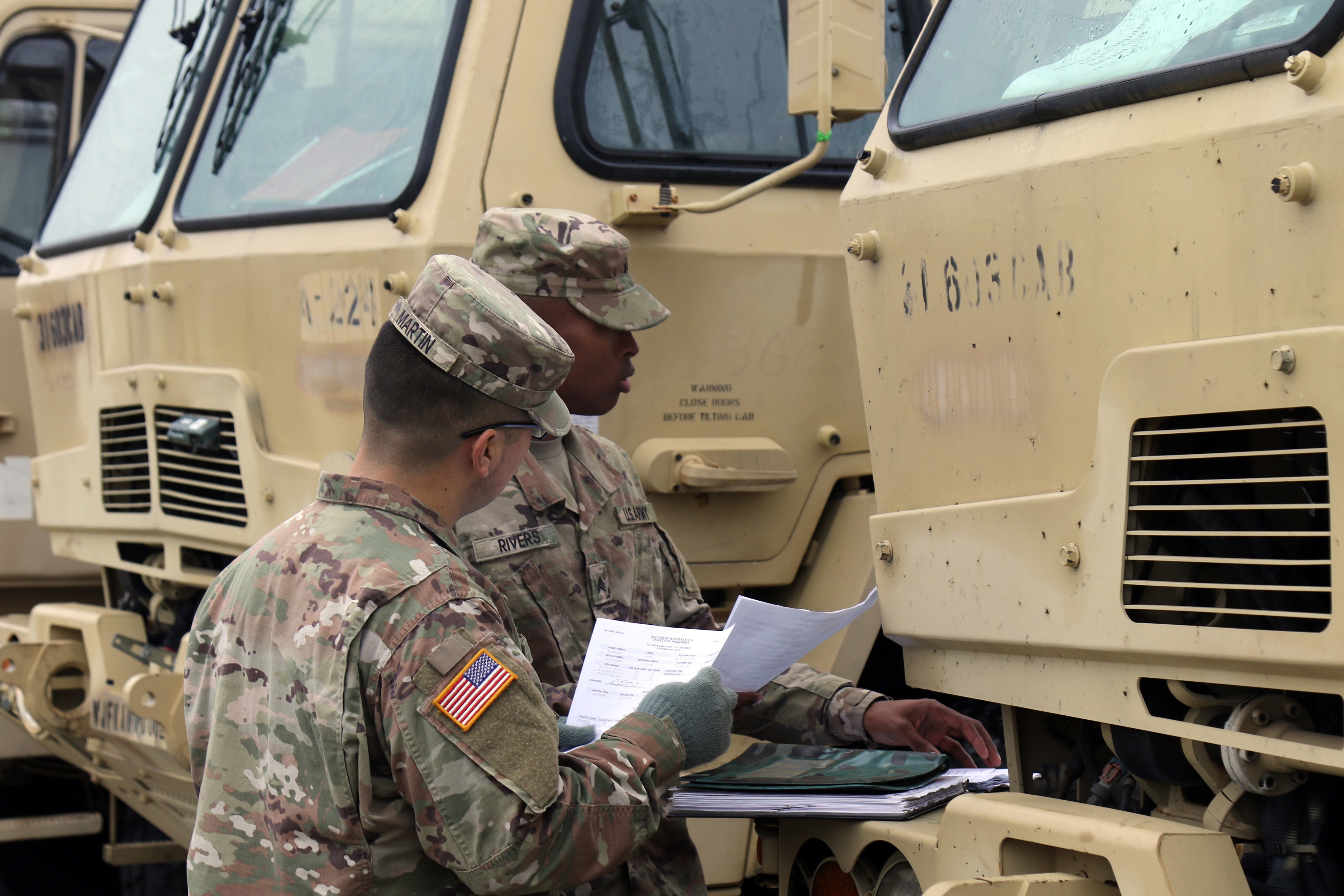

Understanding Your Maintenance Structure and Leadership Dynamics

As an XO, it’s crucial you understand the structure of your maintenance organization and the dynamics between its key players. In an ABCT formation, your maintenance team consists of the 91-series maintainers, each with specialized roles. These maintainers primarily operate within the forward support company/troop (FSC/FST), with most assigned to the base maintenance platoon. A smaller contingent is detached to line troops as part of their field maintenance team (FMT). It’s your responsibility as XO to ensure the FMT is successfully integrated into the team. A balancing act often arises between the troops and support leadership over accountability and control, with administrative oversight typically managed by the FST and operational priorities set by the line commander. The bottom line is that FMTs are part of your formation, and their success in maintenance operations will directly impact your overall operational readiness (OR) rate. Incorporate them into your team.

The maintenance control section (MCS), a crucial part of the maintenance structure, oversees and coordinates the squadron’s maintenance efforts. Consisting of the squadron maintenance officer, the maintenance control officer, the squadron maintenance technician, the maintenance control sergeant, and the maintenance platoon leader, the MCS aligns with the Command Maintenance Discipline Program (CMDP). This alignment provides a clear strategic direction and ensures that your role in the squadron’s maintenance efforts is significant and well-defined.

Logistics and Supply Chain Oversight

As XO, a key part of your role is overseeing logistics and supply chain operations. To be prepared and confident in this role, you need to be familiar with SSA operations, including how your unit interacts with this organization for requisitioning parts, equipment, and supplies. It’s also important to understand the timelines for ordering critical items and establish a relationship with the SSA accountable officer to streamline processes. Additionally, you need to get to know the Army Oil Analysis Program (AOAP) and its role in predictive maintenance — ensuring oil samples from vehicles and equipment are submitted on schedule can prevent major mechanical failures down the line.(4) You’ll also need to coordinate with the test, measurement, and diagnostic equipment (TMDE) support team to ensure the calibration of tools and equipment are up-to-date as this directly impacts maintenance accuracy and safety.(5) Be proactive in planning and preparing for equipment drop-off and pick-up dates; this forethought will be common themes for success, as it ensures you are always one step ahead in your logistics and supply chain operations.

Managing the Shop Stock List for Operational Efficiency

Overseeing the shop stock list (SSL) is critical to ensuring maintenance operations run smoothly and equipment downtime is minimized. The SSL, consisting of demand-supported repair parts and consumables your unit is authorized to stock, enables rapid repairs for high-demand items without delays from external supply chains. Managed through GCSS-Army, the SSL categorizes items as either demand supported (ZV line) or command supported (ZM line). You must understand the need for regular validation — typically every 90 days — to ensure the list aligns with usage patterns and mission needs. You should also be familiar with analyzing demand data to adjust stock levels, as overstocking can tie up resources while understocking risks mission delays. Coordinating with your MCS to maintain an accurate SSL will ensure your unit can sustain operations. Honor the space you physically have for SSL item storage and turn in whatever the analysis concludes your unit no longer needs. Do not hoard items; this will inevitably induce an inventory nightmare and disrupt operations.

Training and Soldier Development

As an XO, your commitment to ensuring the readiness of your maintenance team and Soldiers through regular technical training is paramount. Coordinate with your unit’s training officer to schedule these sessions, focusing on new equipment and updated procedures. Developing crew members into 15-level troubleshooters for their equipment will significantly enhance your unit’s capability. For instance, if your unit has recently received upgraded M1 Abrams tanks, the 91A mechanics (M1 Abrams Tank System Maintainers) must receive hands-on training with the new systems and have crew members present during their walkthrough.

You must also recognize the significant impact of integrating maintenance training within the unit’s broader training calendars. For instance, incorporating vehicle recovery drills into field exercises improves technical skills and builds cohesion between the maintenance teams and the line troops. This integration is a crucial part of your role. Don’t overlook the potential of your NCOs; encourage them to attend courses like the Advanced Leader Course (ALC) to enhance their ability to manage maintenance operations under pressure. For platoon leaders and high-performing NCOs, the Maneuver Leaders Maintenance Course (MLMC) is critical for leaders’ understanding and knowledge of proper maintenance execution and planning. This course will prepare NCOs to become platoon sergeants and platoon leaders to take XO positions, yielding more competent future commanders and first sergeants.

Financial and Accountability Procedures

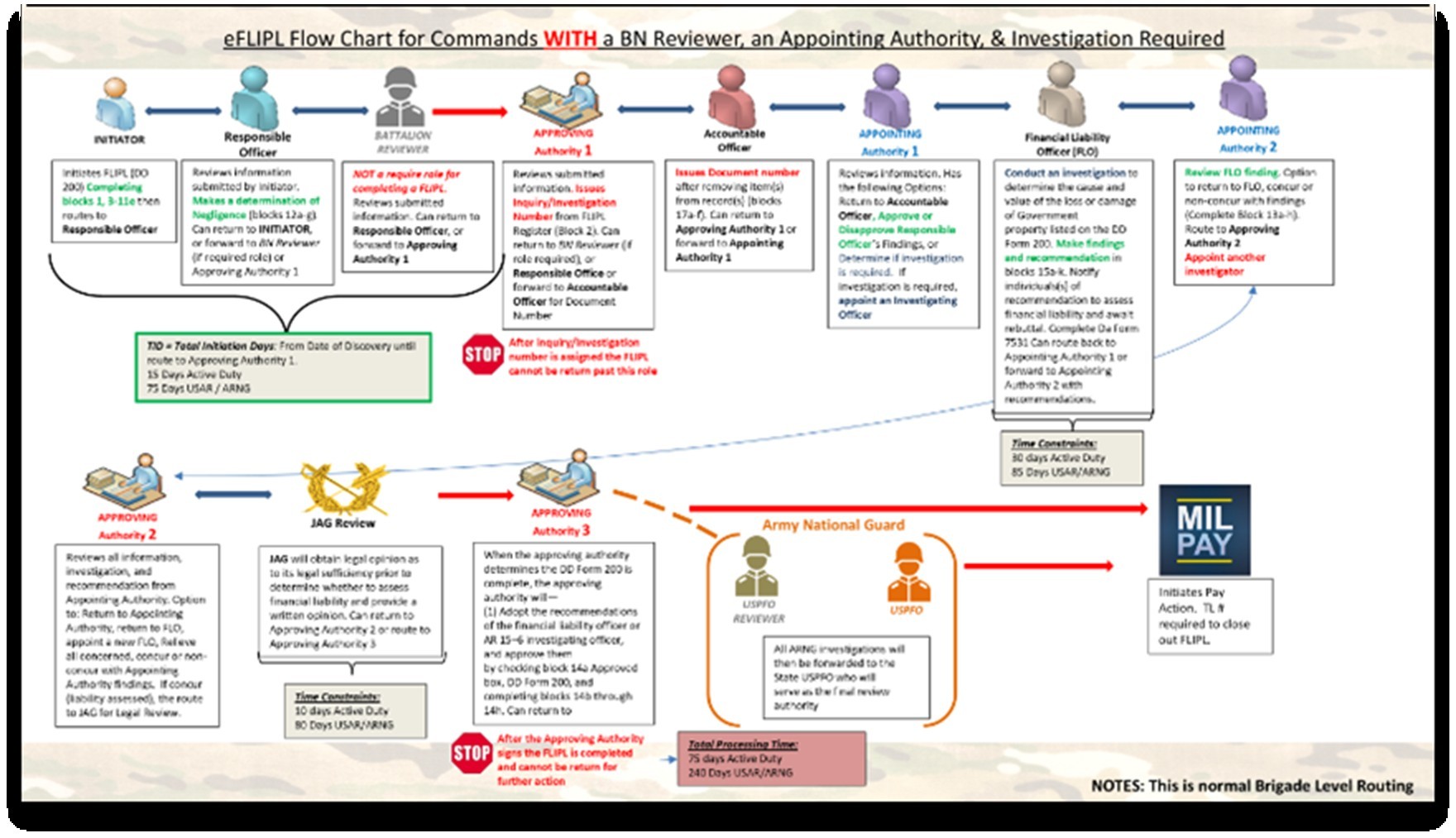

Another critical area is managing financial liability and accountability. Beyond the Financial Liability Investigation of Property Loss (FLIPL) processes, you are responsible for assisting the commander with the accountability of all property book items during inventories.(6) Work closely with your property book officer (PBO) to conduct CSDP inspections, ensuring compliance with Army regulations, as well as pay close attention to sensitive items (SI) like night-vision devices or weapons. Remember, discrepancies in SI can lead to serious consequences, underscoring the importance of your role.

Additionally, familiarize yourself with tracking equipment status and maintenance costs, which will help you justify budget requests during resource meetings. If at all possible, avoid using a manual tracking system regardless of your Excel proficiency. Removing multiple trackers will empower you to eliminate human input errors and investigate products already established at higher levels, increasing efficiency. In units like the 3rd Infantry Division, you may be able to adopt higher best practices like “COP of the Rock,” a live Power BI tracker utilizing real-time updates from systems of record like GCSS-Army. Don’t recreate the wheel unnecessarily!

Figure 2 — Example of an eFLIPL Flow Chart

Communication and Reporting

As an XO, your role is pivotal in the battalion or brigade. Mastering the art of concise and actionable reporting during maintenance meetings at all echelons is a key part of your responsibility. Be prepared with data on your unit’s readiness metrics, such as OR rates, and be ready to discuss how maintenance impacts training schedules. For instance, if a critical piece of equipment is non-mission capable, outline a clear plan to get it back online and request support if needed. Look across the formation within the battalion and brigade; this separates a good XO from a great one.

Your unit’s timely submission of operational readiness inspection lists is crucial. These reports directly influence higher headquarters assessments of your unit’s combat readiness, making your role in resource management integral to the mission’s success. By ensuring unit training according to the 8-Step Training Model and validating planning during the training resource meeting, you empower your unit to be at its best. Maintaining open lines of communication with your commander, providing them with regular updates on maintenance and logistics challenges, and actively seeking guidance on prioritizing resources are all essential for efficient resource allocation and mission success.

Building Relationships with Higher Echelons

You play a crucial role as the bridge between your unit and its higher headquarters. Your attendance at battalion/brigade-level meetings with a clear understanding of your unit’s needs, whether additional funding for parts, control exchange requests, or support for a large-scale maintenance operation, is vital. These meetings are an opportunity to advocate for your commander’s priorities. Building relationships with the battalion/brigade S-4 and legal teams is also important, as it ensures the smooth processing of administrative actions such as equipment turn-ins or lateral transfers. By fostering these connections, you’ll secure the resources and support your unit’s needs to maintain its operational tempo.

Maintenance Meeting

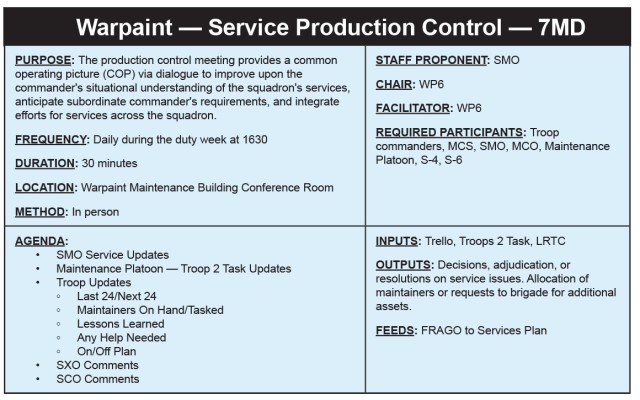

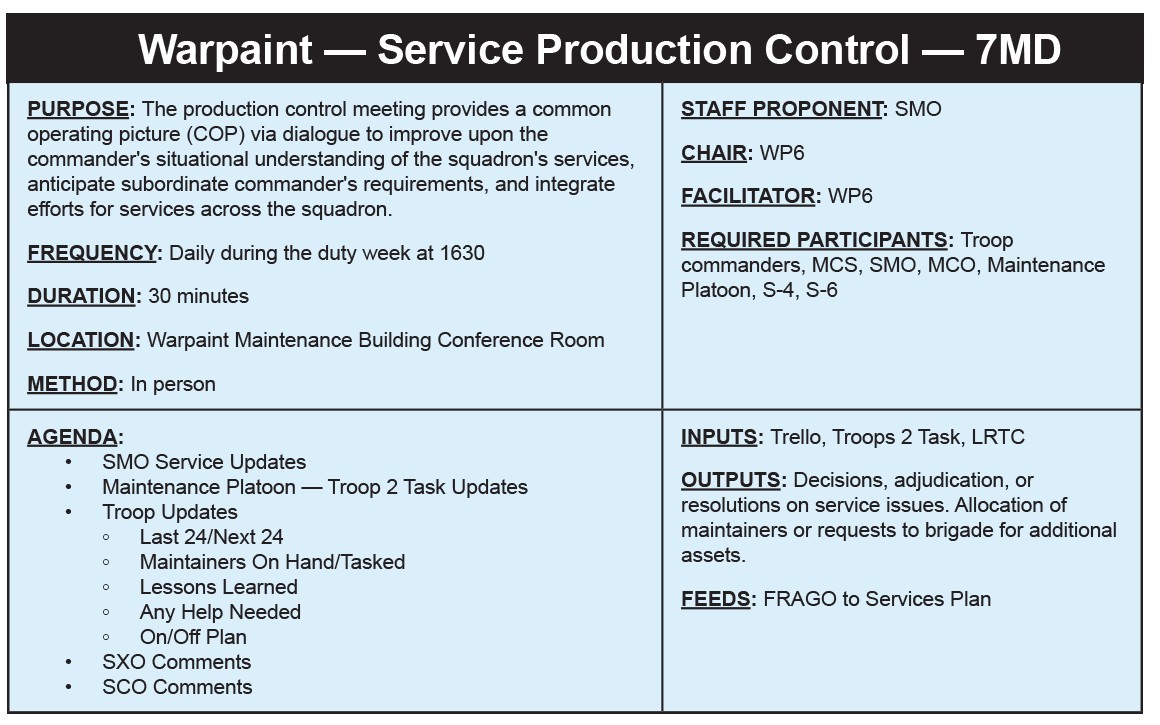

The last point is in regard to how you conduct maintenance meetings and the efforts you make in preparation. As a battalion/squadron XO, you should run two types of maintenance meetings: the weekly maintenance meeting and your production control meeting (PCM). These are two completely different meetings. A battalion/squadron maintenance meeting focuses on NMC-S vehicles and forecasts additional information: services (vehicle and ancillary), overaged repairable item list, and AOAP — the “deep fight.” The PCM focuses on all NMC-M vehicles, prioritizing assets by bumper number with an estimated completion date (ECD) — the “close fight.” As an XO, you must prepare for these meetings, attend with a clean and updated ESR, understand the status of parts for all vehicles, and articulate what help is needed from higher. All too often, maintenance meetings delve into a review of the ESR, with the “big XO” going line by line through the report — this is a waste of time and something the company/troop/battalion XOs and their team chiefs should conduct prior. Have a “7-Minute Drill” that outlines the agenda of the meeting with inputs and outputs — this will ensure that the meeting stays on track rather than turning into a working group.

The battalion/squadron should conduct the PCM in the morning while your organization conducts formation and sets the conditions in the motor pool to execute maintenance operations. This meeting is an opportunity for you to drive quick wins and confirm with the team that the MCS has assigned the correct maintainers to specific work orders. This confirmation is a crucial part of the process, as it ensures that the right people are working on the right tasks, leading to maximum efficiency and productivity. It also allows the team to prioritize assets and vehicles daily, further empowering you to control the maintenance operations.

Preparation is key to the success of these meetings. You need to be prepared with an updated ESR, a “troop to task” to understand the capacity you must conduct maintenance, and a clear understanding of the resources and help you need from higher to tackle required maintenance. This level of preparation will ensure that the meeting is focused and productive and that any necessary decisions will be driven swiftly and effectively.

Figure 3 — Example Production Control Meeting “7-Minute Drill”

Conclusion

So now you’re an XO — embrace the crucible of leadership where every decision you make directly impacts the unit’s operational success. The responsibility for your unit’s readiness falls squarely on your shoulders, with significant implications for mission outcomes. You are the key coordinator, overseeing everything your unit does and ensuring your Soldiers are fully equipped and prepared for any operational environment. Take on this role with diligence, and remember, challenges are not obstacles but opportunities to learn and grow. Welcome the challenge with the capacity to learn and forge the backbone of a combat-ready force. This position is an opportunity for growth and learning.

Notes

1 GCSS-Army — https://www.gogcss-army.army.mil/welcome.html.

2 From Department of the Army Pamphlet 750-8, The Army Maintenance System (TAMMS) Users Manual, NMC-S: Non-mission Capable Supply — this code refers to equipment awaiting a part or supply; NMC-M: Non-mission Capable Maintenance — this code refers to equipment awaiting troubleshooting or maintenance time to repair; NMC: A material condition indicating that equipment cannot perform any one of its combat missions. NMC is divided into not mission capable maintenance (NMCM) or not mission capable supply (NMCS). See DA PAM 750-8, 22 August 2005, 308.

3 Equipment Status Report (ESR), U.S. Army Combined Army Doctrine Directorate, https://www.youtube.com/watch?v=CIZ5uDjGRmE&list=PLPbbRw97BH2ugLMp9oIUcTlBD5f0oLOrY.

4 AOAP: Army Oil Analysis Program (AOAP) — Part of a Department of War-wide effort to detect impending equipment component failures and determine lubricant condition through evaluation of used oil samples. See DA PAM 750-8, 22 August 2005, 304.

5 TMDE: Test, Measurement, and Diagnostic Equipment (TMDE) — Any system or device capable of being used to evaluate the operating condition of a system or equipment to identify and/or isolate any actual or potential malfunction. TMDE also includes automatic test equipment and test program sets. See DA PAM 750-8, 22 August 2005, 311.

6 FLIPL: Financial liability investigation of property loss — An instrument for recording circumstances concerning loss, damage, destruction or theft (LDDT) of Army property. It serves as, or supports, a voucher to adjust property records on which the property is listed. It also serves to determine any question of responsibility (financial or otherwise) for absence or condition of the articles. See AR 735-5, 10 March 2024, 117.

MAJ Jonathan Buckland currently serves in the J33 on the Joint Staff. His previous assignments include serving as the executive officer of 5th Squadron, 7th Cavalry Regiment, 1st Armored Brigade Combat Team (ABCT), 3rd Infantry Division; operations officer for 3rd Battalion, 69th Armor Regiment, 1/3 ABCT; and future operations (FUOPS) chief for 3rd ID. He has a bachelor’s degree in English from the Virginia Military Institute, a master’s degree in international studies from the University of Kansas, and a master’s in operational studies from the Army Command and General Staff College, Fort Leavenworth, KS.

1LT Ryley Bendewald currently serves as a squadron maintenance officer for 5-7 CAV, 1/3 ABCT. His previous assignments include serving as a FUOPS officer, scout platoon leader, and scout troop executive officer in 5-7 CAV. He has a bachelor’s degree in economics from the University of Southern California (USC), Los Angeles, CA.

This article appears in the Winter 2025-2026 issue of Infantry. Read more articles from the professional bulletin of the U.S. Army Infantry at https://www.benning.army.mil/Infantry/Magazine/ or https://www.lineofdeparture.army.mil/Journals/Infantry/.

As with all Infantry articles, the views herein are those of the authors and not necessarily those of the Department of War or any element of it.

Social Sharing