By Justin (Doug) Cook, Chief, Advanced Manufacturing Branch

Corpus Christi Army Depot, Texas - The depot continuously strives to be a leader in transformation, utilizing new technologies to support the warfighter faster and safer. As a result, Corpus Christi Army Depot installed a new grinder in the Aviation Multipurpose Production Facility.

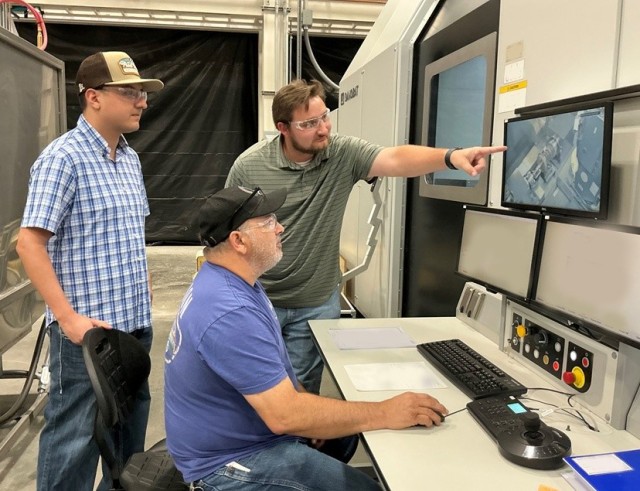

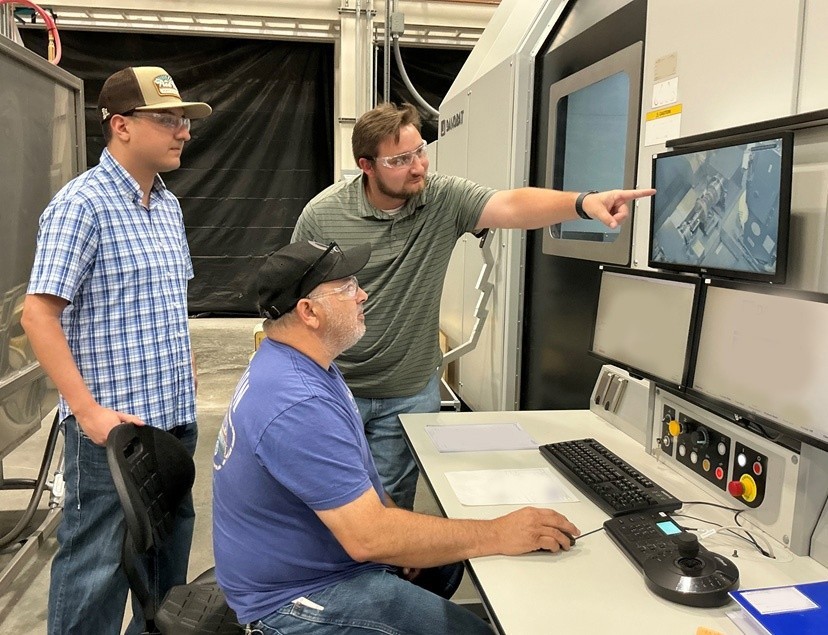

Recently, while performing start-up testing, the original equipment manufacturer performed a series of inspections and procedures to confirm the machine is operating correctly. Justin Vance, a general engineer, saw that the in-process Laser Measurement Gauge's proximity sensor moved uncomfortably near the master rotor. The distance between the laser and the rotor is set by touching off from a specific area on the crash bar and storing that location as a software safety feature to prevent the grinder from crashing into the part.

"This was one of those moments when you see the machine operating as designed at CCAD and can visualize potential issues," said Justin Vance, general engineer.

Vance collaborated with the OEM to design a crash bar extension to provide additional safety. A short suspense occurred, and the depot had to provide a crash bar extension and a safety feature, preventing the grinder from damaging the part, before the OEM departed from CCAD. Any delay in addressing this issue would have postponed the acceptance testing of the grinder, a delay would have adversely affected CCAD's production.

"This modification will ensure that collisions are prevented, effectively avoiding potential damage to both the machine and the part," said Vance. "As well as preventing any loss in production time and capability."

Austin Vallejo, Matthew Nolder and Matthew Burton were among other engineers recruited onto the team. After analyzing the OEM's design and recommendations to machine the crash bar extension from aluminum, the engineers proposed that the item could be 3D printed at the depot using a polymer, which is a synthetic plastic material.

The aim was to convert the two-dimensional sketch into a 3D model, have a file ready to start printing within three hours, and 3D printers operate overnight. The 3D printers were used to print three crash bar extensions composed of nylon, polycarbonate or carbon fiber. With the project successfully completed, the nylon-carbon fiber was selected and installed on the grinder.

"Interest in additive manufacturing is growing," said Vallejo. "This project highlights its benefits by providing a timely, cost-effective solution that demonstrates the technology's impact on mission readiness and operational efficiency."

Social Sharing