Preventative maintenance is important for many things—cars, homes and even our bodies. Keeping things healthy and running smoothly helps prevent major breaks or failures throughout the course of a life. The same is true for dam and levee relief wells.

Some dams and levees are built with a system of water wells, which are constructed downstream to relieve excess pressure in the foundation. These relief wells experience natural build-up and need to be cleaned, roughly every three to five years, to ensure water can flow freely.

“The biological build-up is a result of naturally occurring bacteria in the groundwater that can rapidly spread and block or reduce the flow of a well,” said Brandon Harmon, geologist with the Kansas City District, U.S. Army Corps of Engineers.

Various methods exist to clean the relief wells but often require the use of harsh chemicals and special equipment. Using harsh chemicals is not only a safety risk to the people cleaning the relief wells, but also to the environment.

“[The operators use] oxalic acid in combination with a high temperature water treatment. It’s not as safe to work with a high strength acid in combination with high temperature water,” said Dr. Clint Smith, senior research biologist with USACE’s Engineer Research and Development Center Geospatial Research Lab. “It can destroy clothes, have high risk for burning the operators cleaning the wells and a lot of it can destroy the environment.”

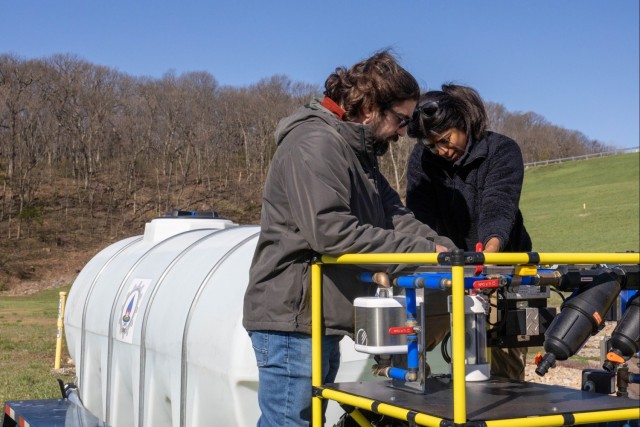

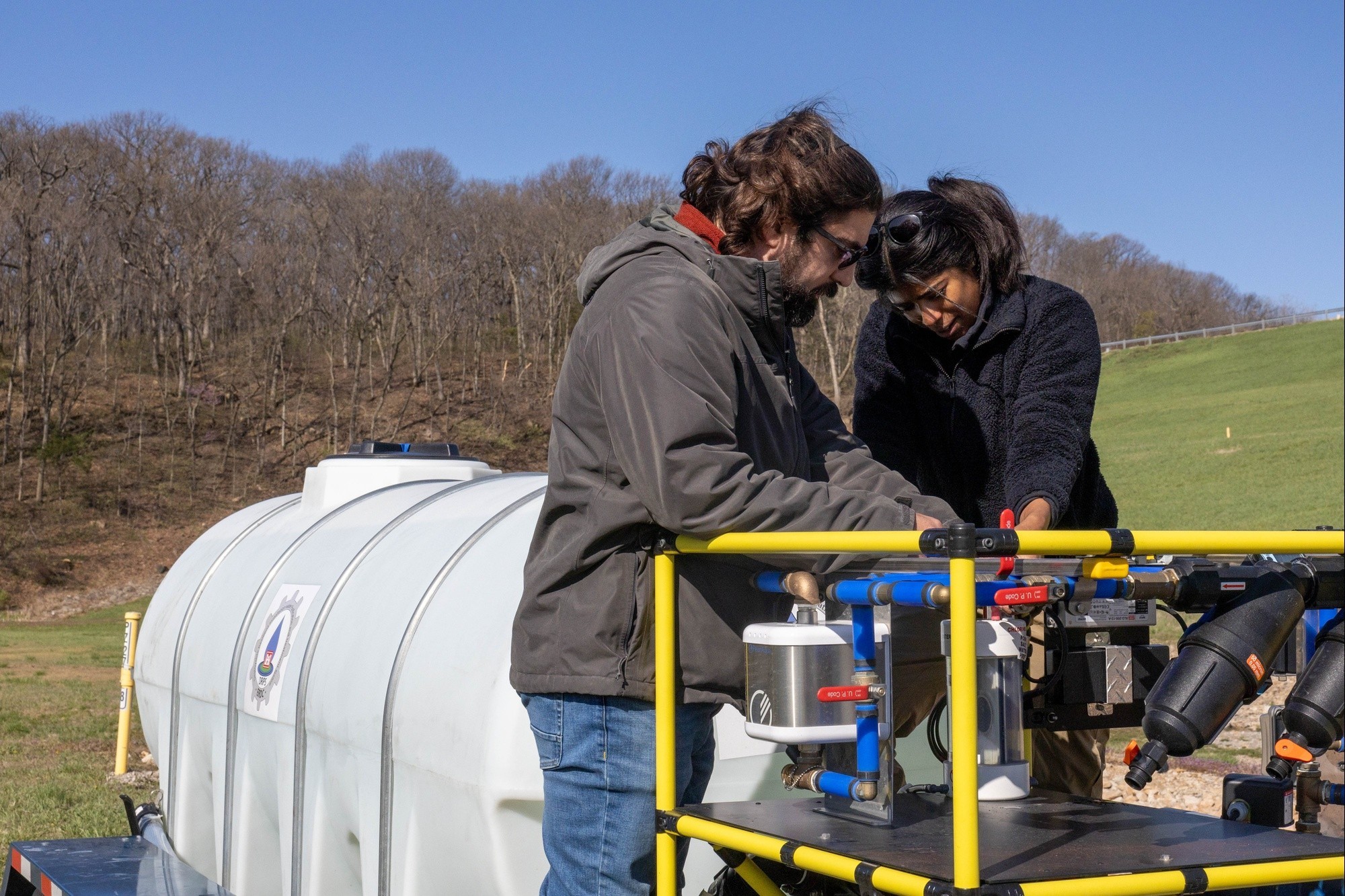

Luckily, researchers, scientists and engineers at the Engineer Research and Development Center developed a Relief Well Sustainment - Deployable Resilient Installation Water Purification and Treatment System, which despite its long name is a much safer, simpler method for cleaning relief wells. Perry Dam in the Kansas City District recently tested the innovative system on its relief wells.

“This test is in the middle of the normal three-year rejuvenation cycle and will reduce the amount of biological build-up allowing the wells to flow more efficiently until the next [one,]” said Harmon. “[The Engineer Research and Development Center team] will demonstrate the process, and their intent is to provide the Kansas City District with the system to continue to use for future well rejuvenation efforts.”

Developed in 2022, the Relief Well Sustainment - Deployable Resilient Installation Water Purification and Treatment System uses table salt to create chlorine via gas infusion, which is then pumped into the relief well using water already available at the dam. According to Dr. Smith, this method is much safer than other methods used in relief well rejuvenation.

“For the system that we use, all you must do is bring out enough salt to operate the system for the number of wells that you need to treat that day. For this effort, the cost of salt to treat the relief wells at Perry Dam was less than six dollars, which filled the 1,000-gallon tank at least three times. There’s a lot less hazardous materials that you’re hauling around,” said Dr. Smith. “A little bit of high-strength bleach might bleach your clothes, but it’s not as hazardous as an acid on your clothes or skin and it dissipates in the treatment process—it doesn’t linger in the reservoir.”

After the chlorinated water is pumped into the relief well, it will sit overnight before being pumped out of the well.

“The air lifting is essentially pumping air into the bottom of the well and all the debris comes out,” said Dr. Smith. “It helps keep a healthy flow for normal operation and reduces stress for the extended life of the dam or levee.”

While safety is always USACE’s number one priority, the Relief Well Sustainment - Deployable Resilient Installation Water Purification and Treatment System is easy to transport and requires no special tools to operate. Furthermore, the innovative system has a cost saving benefit. According to Smith, table salt costs about 30 cents per pound, whereas oxalic acid costs about one dollar per pound, or higher, depending on the purity.

The Kansas City District alone has several dozen relief wells at its dams. Over time, the cost savings of using the Relief Well Sustainment - Deployable Resilient Installation Water Purification and Treatment System start to add up significantly.

“If you start calculating for treatment of 100 wells and if you did it over five years, it would be $10 for salt and $275,000 for oxalic acid,” said Dr. Smith. “It gets into the millions after 100 years, so you can start to see the cost savings.”

As critical infrastructure, dams and levees must be properly maintained to ensure they perform effectively during flood events, protecting both life and property. Smith and his team are happy to teach USACE geologists and drill crews out in the field how to use their innovative system as part of routine dam and levee maintenance.

Their hope is to get more Relief Well Sustainment - Deployable Resilient Installation Water Purification and Treatment Systems to more districts in USACE as a safer, more efficient method for relief well rejuvenation. Additionally, the team is hoping to bring down the cost of the overall system by reducing its size while maintaining its impact on the relief well treatment process.

“It’s kind of like going to the dentist or to the doctor. If you go periodically, then it’s not so bad. If you don’t go for 30 years and your arteries are bad, you might need surgery,” said Dr. Smith. “It’s the same idea—if we treat [relief wells] and we treat them often, that’s a return on investment.”

Social Sharing