ROCK ISLAND ARSENAL, Ill. — Senior leaders from across the U.S. Army plan to gather this week at Rock Island Arsenal-Joint Manufacturing and Technology Center for a two-day war game about advanced manufacturing.

The session will focus on enhancing and synchronizing efforts so the Army can best leverage technology to achieve its modernization and readiness goals.

Advanced manufacturing is a potential game-changer for how the Army designs, produces, delivers and sustains materiel capabilities. It involves the use of new technologies to create or improve products and processes.

The Dec. 4-5, 2024, war game is a U.S. Army Materiel Command event. The U.S. Army Tank-automotive and Armaments Command, a major subordinate command of AMC, is hosting it.

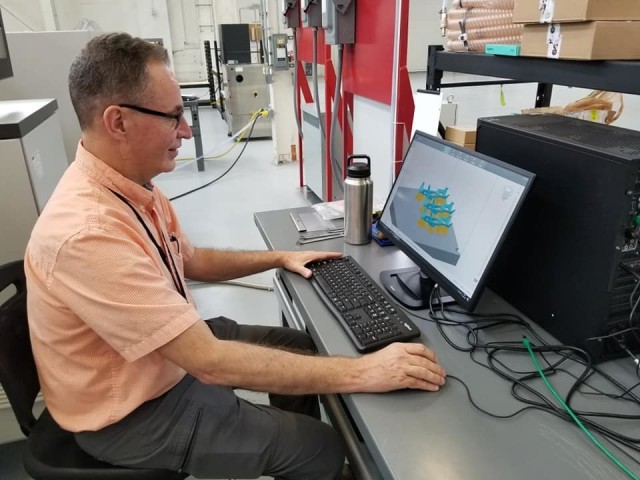

The Army is continually adapting to stay at the forefront of innovation as technology evolves. One major area of focus in recent years has been additive manufacturing, or 3D printing. Officials say the technology has the potential to transform battlefield logistics through on-demand fabrication of parts closer to the point of need.

In early 2024, TACOM launched the Battle Damage Repair and Fabrication effort. Under that program, RIA-JMTC is printing temporary replacement parts such as battery tray mounting brackets and bearing covers to be shipped to the field.

RIA-JMTC develops, manufactures and delivers readiness solutions for the Army and Department of Defense systems across the globe. It has a variety of conventional and advanced manufacturing capabilities, such as 3D printing and traditional forge and foundry work combined with innovative technologies, processes and equipment.

In addition, additive manufacturing kits have been recently added to some Metal Working and Machining Shop Sets, which are mobile containers equipped with tools to build and repair parts in the field.

Other advanced manufacturing methods include artificial intelligence, robotics and machine learning. AMC is responsible for planning and executing the Army’s advanced manufacturing strategy.

While advanced manufacturing won’t replace traditional supply chain methods, officials say, it will enhance the resources that are available to warfighters and play a significant role in the modernization of the Army’s Organic Industrial Base.

Social Sharing