NATICK, Mass. -- Everyone has heard stories about the recent outbreaks of Salmonella in a variety of foods, such as peanut butter, tomatoes, fresh jalapenos and pistachios, and Escherichia coli in leafy green vegetables, such as lettuce or spinach.

Eating fresh fruits and vegetables contribute to a healthy diet, but outbreaks as those mentioned above raise significant alarm among consumers and public health officials concerned with consumer safety, the safety of the food chain from agri-terrorist threats, and the safety of produce procured from host nations, where pesticides are less prevalent and hygiene standards are not as stringent as in the United States.

In this "critical time" for food safety, according to the U.S. Food and Drug Administration (FDA) Commissioner Dr. Margaret A. Hamburg, the FDA is setting and enforcing tougher standards for the riskiest products, starting with fresh fruit and vegetables.

Food safety expert researchers from the Natick Soldier Research, Development and Engineering Center (NSRDEC) have been working on solutions to this challenge. Specifically, NSRDEC researchers developed the Portable Chemical Sterilizer (PCS) and the Disinfectant-sprayer for Foods and ENvironmentally-friendly Sanitation (D-FENS) as new ways to achieve the goals of eliminating pathogens, such as Listeria monocytogenes and E. coli, from fresh produce commodities and to ensure the safety of the food processing and handling environments, while also working to keep our environment safe using "green" technology.

The PCS and D-FENS are novel and innovative technologies that have been thoroughly tested and are presented in the book "Microbial Safety of Fresh Produce." Published by Wiley-Blackwell as part of the Institute of Food Technologists Press Series, "Microbial Safety of Fresh Produce" was also edited by NSRDEC scientists in collaboration with experts from U.S. Department of Agriculture (USDA) and Cornell University. The PCS and D-FENS are featured in the chapter "Enhanced Safety and Extended Shelf Life of Fresh Produce for the Military" written by NSRDEC scientists, a leading oxyhalogen chemistry expert from Brandeis University, and a leading bacterial spore expert from the University of Connecticut Health Center.

Both the PCS and D-FENS are environmentally friendly technologies because they rely on the use of chlorine dioxide, which works at lower concentrations and produces significantly lower quantities of dichlorinated by-products compared to other types of disinfecting sanitizers such as chlorine bleach rinses or chlorine gas. Chlorine dioxide is well-known for its potent anti-microbial action in commercial disinfectant and sanitation applications. Chlorine dioxide is registered by the U.S. Environmental Protection Agency (EPA) for use in food processing, handling and storage plants, and by the FDA for washing minimally processed fruits and vegetables to eliminate spoilage microflora, vegetative pathogens, viruses and tough-to-kill bacterial spores.

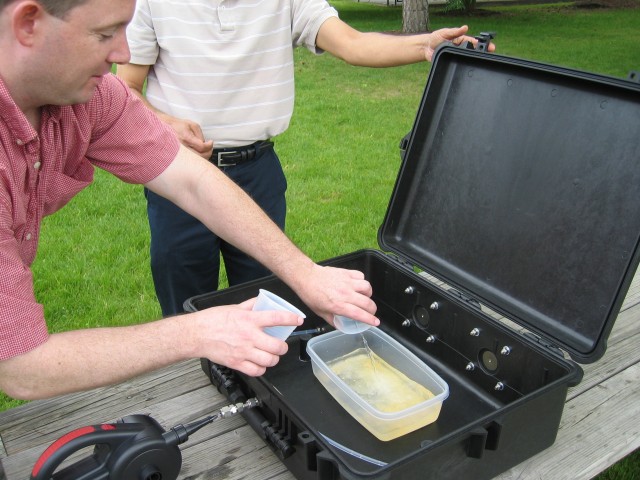

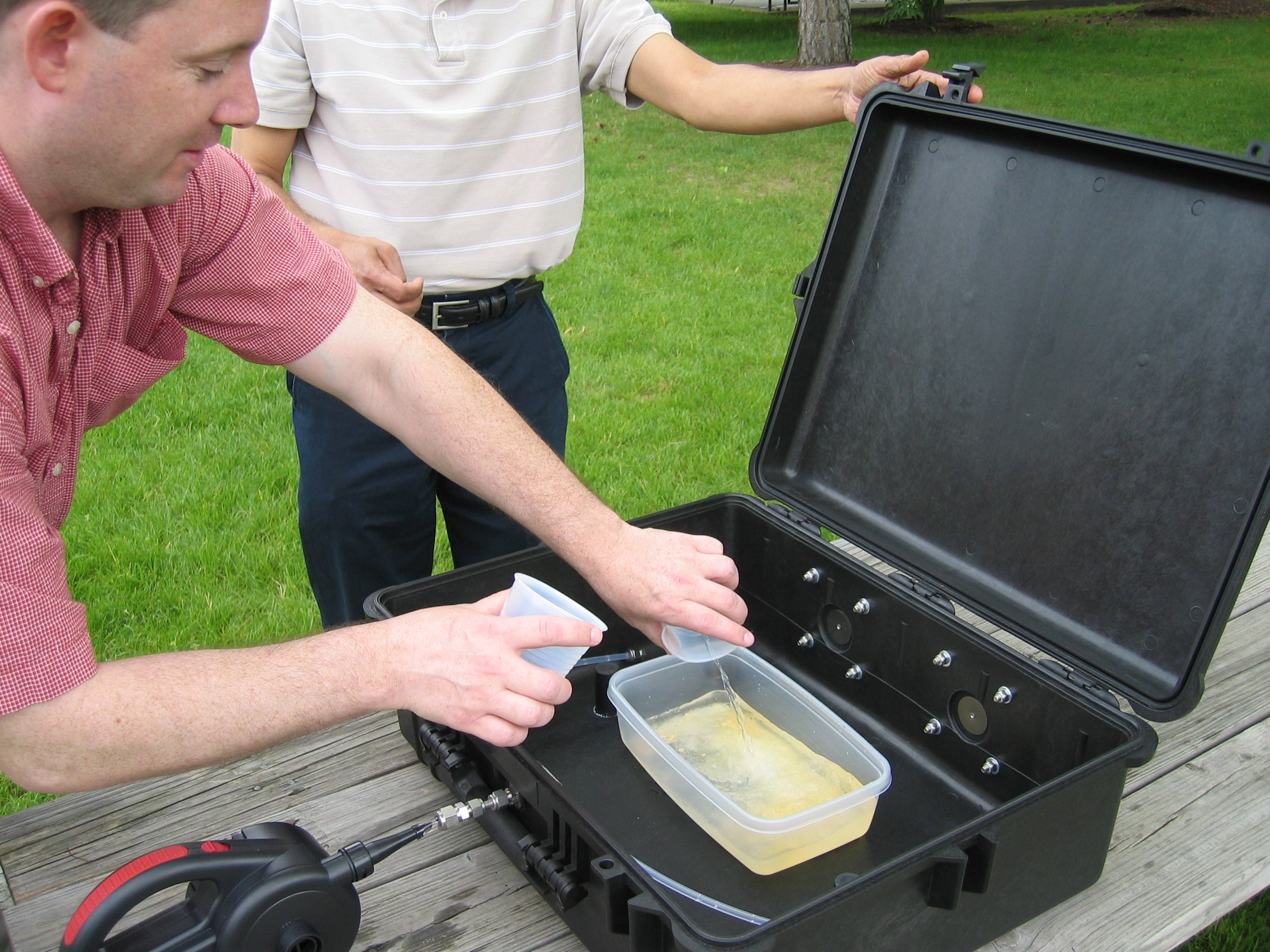

The PCS is an energy-independent, portable plastic suitcase that uses a small set of common chemicals to generate gaseous chlorine dioxide on-site within minutes. Because of its capabilities on food items, the researchers have begun testing chlorine dioxide gas to kill bacteria on produce such as tomatoes to ensure it can be done without causing problems with appearance or taste. The PCS can also prevent browning that commonly occurs in items like sliced apples. Results at this time are so promising that further extensive testing with a broad range of food items is planned in conjunction with the USDA under an agreement with NSRDEC. In the future, the PCS could potentially be used to protect Warfighter health from foodborne illnesses by eliminating dangerous pathogens from fresh fruits and vegetables before they are consumed.

Another important way to protect Warfighter health and prevent the possible spread of diseases is by creating and maintaining good sanitation practices in small, shared spaces or anywhere a large number of personnel exist in a shared living environment. For example, the military needs to prepare, serve, and clean-up food in austere conditions in deployed locations around the world. Many times this is done in battlefield kitchens, for which there is an important need to ensure proper food and food equipment sanitation, to maintain the health of our Warfighters. Similarly, good hygiene and sanitation are also important for Combat Surgical Hospitals (such as Deployable Medical Systems), showers, latrines, and other such facilities. The D-FENS technology offers a potential solution to meet these needs.

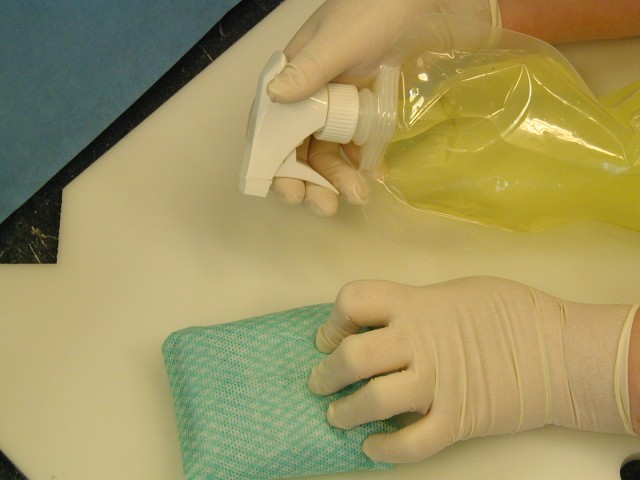

D-FENS generates a safe, user-friendly chlorine dioxide solution within a few minutes that can be sprayed on surfaces and then conveniently wiped away, to easily create and maintain good sanitation practices by reducing bacteria such as E. coli, L. monocytogenes, and Staphylococcus aureus on surfaces and preventing the possible spread of diseases by secondary contamination.

D-FENS uses a commercially available handheld, collapsible spray-bottle made of a flexible plastic pouch material to mix small quantities of safe, dry reagents with available water sources. The item is small, compact, and easily transportable, to reduce the logistics burden. The bottle's pouch has a gusseted bottom that opens for the bottle to stand upright when full of disinfectant solution, and the material it is made from is chemically resistant so it can be used multiple times. The chlorine dioxide solution is not acidic or reactive. At the end of a work shift, any excess solution remaining in the D-FENS pouch spray bottle can be used to sanitize trash receptacles or purge bio-films that can cling inside drains.

NSRDEC's patent applications relating to the D-FENS and PCS technologies have transferred via Patent Licensing Agreements (PLA's) to three companies in the public sector for commercialization and use, in accordance with the Federal Technology Transfer Act. Most recent among them is a PLA with the chlorine dioxide company ClorDiSys Solutions, Inc., Lebanon, N.J., that NSRDEC signed in May 2009. Previously, ClorDiSys Solutions, Inc. had a successful site-visit to NSRDEC, during which D-FENS was demonstrated. Currently, ClorDiSys Solutions, Inc. has developed packaging systems for the chemical reagents and is selling NSRDEC's home-grown chlorine dioxide technology as a commercial product for decontaminating laboratory biological safety cabinets with tremendous savings in time, convenience, and environmental protection compared to conventional sterilants such as formaldehyde. After their commercialization, these products are available for procurement by military organizations.

The breakthrough nature of these scientific and technical achievements in chemistry and microbiology is demonstrated by the patent applications for the unique PCS and D-FENS technologies, the co-edited book "Microbial Safety of Fresh Produce," a book chapter, and Technology Transfer through PLA's that have been produced. In 2009, this inventive team of NSRDEC chemistry and microbiology researchers was recognized with a Department of the Army Research and Development Achievement (RDA) Award for these accomplishments.

Dr. Marilyn M. Freeman, NSRDEC director, stated that the RDA Awards recognize scientists for their proven scientific and technical excellence and the potential for their contributions to improve the Army's capability and enhance our national defense.

Maj. Gen. Paul Izzo, commanding general, U.S. Army Research, Development, and Engineering Command (RDECOM), also recognized the significance of these accomplishments and the 2009 RDA Award. He congratulated the winners for supporting the Army and the Soldier, and for bringing great credit to themselves, management staff, and the Command.

Dr. Christopher Doona, senior research chemist, NSRDEC's Materials and Defense Sciences Division, said, "We're very grateful to the Department of the Army, RDECOM, and NSRDEC for recognizing and celebrating our accomplishments in this way. As researchers, we're very proud that these scientific accomplishments may actually help benefit the Warfighter, and we're thankful to our teams and directorates for affording us the opportunity to contribute our expertise to the NSRDEC mission and acknowledging our research with this award."

Social Sharing