Napoleon famously said, “Amateurs discuss tactics; the professionals discuss logistics.” The counterinsurgency (COIN) fight has left many first sergeants (1SGs) lacking knowledge and experience about sustainment operations, particularly in rifle companies. Resupplying a rifle company is a deliberate operation that takes planning and ingenuity. While there are many ways to conduct resupply operations, my intent is to help rifle company 1SGs understand that sustaining the company is their responsibility. In large-scale combat operations (LSCO), sustainment operations are the lifeblood of the fight.

Logistics sets the tempo and depth of combat operations. Without procuring and distributing the necessary classes of supply, operations will grind to a halt. Furthermore, failing to address casualty evacuation (CASEVAC) and medical evacuation (MEDEVAC) operations will slow progress and lead to unnecessary friendly deaths on the battlefield. Company 1SGs are the linchpin to mission success; they stand at the crossroads that connects the Soldier with essential items and aid from higher. In concert with the combat trains command post (CTCP) and the forward support company (FSC), 1SGs fuel the fight, often literally. 1SGs’ management of sustainment operations through the company trains and the CTCP is a critical component of successful LSCO.

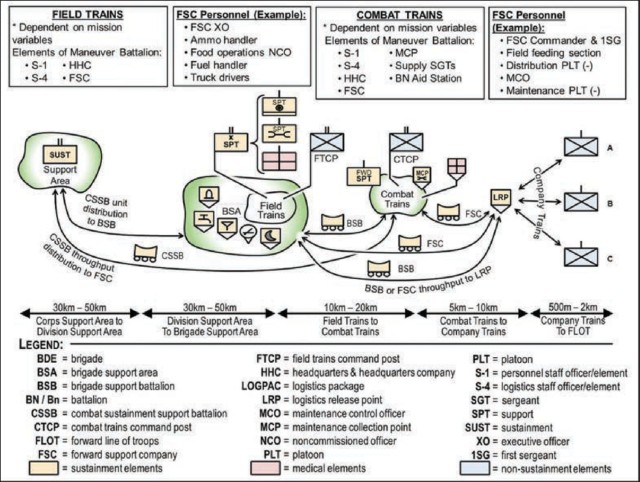

Understanding how the sustainment enterprise functions will help 1SGs understand how the logistics process works and how they can identify friction points. To many maneuver 1SGs, the sustainment enterprise is a mythical creature that magically delivers what they need. Sustainment elements organic to a brigade combat team (BCT) are arrayed across the battlefield to support combat operations. These units position themselves where they can best support the entire brigade, conceal their location in a defendable space, and have adequate room to establish their area of operations. The primary sustainment node for a BCT is the brigade support area (BSA).

The BSA

The BSA contains the bulk of the brigade’s supplies and sustainment assets. The BSA is typically 10-20 kilometers behind the forward line of troops (FLOT), but terrain and the mission weigh heavily on its location. The brigade support battalion (BSB) runs the BSA. The BSB oversees the entire BSA, controls its internal assets, and assists the FSCs. The BSB supplies the FSCs with most of the classes of supply they need to distribute to the battalions. The BSB can offer limited troop transportation capabilities as well. The BSB establishes a role II field hospital, the mortuary affairs collection point (MACP), the supply support activity (SSA), and the ammunition supply point (ASP). Inside the BSA, the FSCs establish field trains command posts (FTCPs).

The FTCP houses the bulk of a battalion’s sustainment capabilities. The FTCP controls the battalion’s maintenance area, bulk water supply, fuelers, wreckers, and field feeding teams. Typically, the FSC 1SG, battalion S1 or S1 NCOIC, the battalion S4 NCOIC, and possibly some supply sergeants or clerks are located at the FTCP. Units place leaders where they will be most effective; therefore, no two BSAs or FTCPs are outfitted the same. The FTCP recovers inoperable vehicles and repairs them. It also gathers the requested items and packages them for efficient delivery to the battalions. The logistics status (LOGSTAT) informs the battalion and specifically the FTCP of needed supplies. The FSC uses its distribution (DISTRO) platoon to deliver supplies to the logistics release point (LRP) that the CTCP controls.

The CTCP and LRP Operations

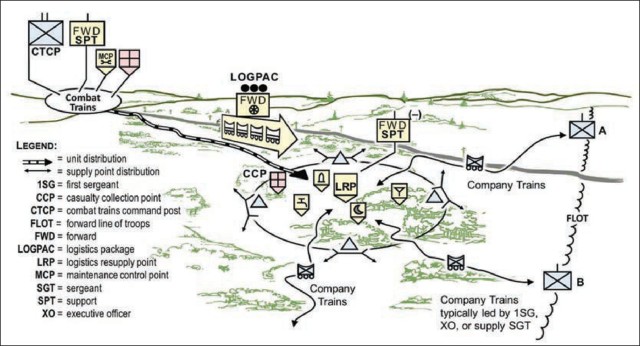

The CTCP is the command-and-control element for the DISTRO platoon once it nears the LRP. The CTCP is typically 5-10 kilometers from the FLOT, but it is close enough to the tactical operations center (TOC) to serve as an alternate command node in the event of TOC displacement. The CTCP may have a variety of leaders positioned at its location, but typically the HHC command team, the battalion medical officer (MEDO), an S1 representative, and a supply representative are at the site. The FSC commander is often at the CTCP as well. The HHC command team will control the CTCP if they are the senior members at the site. The CTCP processes nine-line CASEVAC/MEDEVAC calls, oversees the main aid station (MAS) and forward aid station (FAS), coordinates vehicle recovery operations, and normally has a small transportation capability to assist with emergencies. Finally, the CTCP facilitates the DISTRO platoon’s operation.

The DISTRO platoon is responsible for delivering supplies to the LRP. Once it leaves the BSA, it either travels to the CTCP or contacts the CTCP enroute to the LRP. Normally, the DISTRO platoon goes to the CTCP so it can first drop needed supplies for the CTCP and battalion TOC prior to moving to the LRP. It is the HHC 1SG’s responsibility to facilitate the link up of the DISTRO platoon and the companies’ trains. Depending on the tactical situation and the amount of supplies delivered, the CTCP may escort the DISTRO platoon to the LRP and aid in establishing the site. If DISTRO needs to evacuate remains to the MACP, then it will likely need assistance from the CTCP. The HHC 1SG should serve as a leader who can move to points of friction to aid in recovery, MEDEVAC, CASEVAC, emergency resupply, and other emergent requirements. HHC 1SGs with their limited vehicle and Soldier package can serve as a tremendous combat enabler by being proactive and solving problems when other key leaders are involved in other tasks. The establishment and operation of the LRP is essential to efficient resupply operations.

The DISTRO platoon establishes the LRP at a tactically suitable location that is centrally located to the companies. The LRP and the company resupply point (CRP) are examples of the service-station resupply method. A unit conducts the service-station method by establishing a central distribution site and having subordinate units come to the higher echelon’s location to receive supplies. The DISTRO platoon, which may have help from the CTCP, must secure the area. The Soldiers transporting the resupply should configure loads in a way that facilitates effective distribution of the items.

As each company trains arrives at the LRP, it will conduct link-up procedures in accordance with the battalion’s standard operating procedure (SOP). The company 1SG, executive officer (XO), or supply sergeant who is leading the trains needs to understand what supplies are being picked up and be ready to hand off backhaul items to the DISTRO platoon. The trains should have a small team ready to move the items back and forth as necessary. Depending on the tactical situation and the unit’s preference, company 1SGs may package their supplies for further distribution at the LRP. In a contested environment or if space is limited, the trains may need to move back to the CRP to configure the loads for distribution to the platoons. Company 1SGs can support sustainment operations by planning, being proactive, and efficiently running their trains.

Company Trains

Before 1SGs can sustain their company, they need a plan. Everyone is familiar with the adage, “the 1SG is responsible for beans and bullets.” What does that actually mean? While the company commander is planning the operation, the 1SG and XO split their efforts between conducting troop leading procedures (TLPs), pre-combat inspections (PCIs), and pre-combat checks (PCCs); aiding the maneuver planning process; gathering supplies; overseeing rehearsals; and planning sustainment by phase. The sustainment plan must support and enhance the maneuver plan.

Based off the maneuver plan, the 1SG should be able to identify rates of march and likely enemy the formation will encounter. This information will drive when the 1SG can resupply each platoon and aid in forecasting the types and amount of supplies needed. Paragraph four of the operations order should be robust and outline the days of supplies Soldiers will pack, resupply windows, anticipated locations, LOGSTAT reporting requirements, and methods of distribution — namely tailgate vs service-station resupply. The LOGSTAT must be accurate and timely. A late LOGSTAT limits the S4’s ability to consolidate requests in a timely manner, and it hinders the FTCP from finding and loading the supplies. If time is available, the 1SG should host a sustainment combined arms rehearsal (CAR) and an actual rehearsal. The company trains should be a combat multiplier, not a hindrance to success.

The company trains is the pack mule of a company. Most company trains consist of a differing package of vehicles according to the unit modified table of organization and equipment (MTOE). The most common package in a light infantry company is a light medium tactical vehicle (LMTV) with the water buffalo and the commander’s high- mobility multipurpose wheeled vehicle (HMMWV) with a trailer. Soldier load is rightfully a hot topic across our Army. Dismounted Soldiers often carry between 90 and 140 pounds of mission-essential gear in combat.1 With deliberate planning, the 1SG can drastically reduce the weight some Soldiers carry.

When organized properly, the trains can help reduce Soldiers’ loads. When in the approach march or contact with the enemy is imminent, Soldiers should only carry the items necessary for them to fight and defeat the enemy. We can refer to this as the fighting load. Soldiers normally carry the fighting load in an assault pack or three-day rucksack. Soldiers pack the rest of their field gear in a rucksack, which can be organized and stored in the company trains. While not a correct use of the doctrinal term, we can refer to the rucksack as the sustainment load. What Soldiers need to carry to fight varies according to the mission. The company trains can alleviate some of the burden for Soldiers, keeping them fresh for the fight. Although the trains can support some of the Soldiers’ gear, there are times when the operational environment will dictate that Soldiers carry their full sustainment load.

There are points in the battle where the trains cannot support carrying Soldiers’ sustainment load. While some equipment, such as additional mortar rounds, anti-tank (AT) systems, and other heavy items can be stored in the trains, Soldiers may need to carry their rucksack. The company or platoon can consolidate rucksacks in a ruck plan at the attack position, the company assembly area, or in an objective rally point (ORP). This will allow the element to move on with only the fighting load necessary to accomplish the mission. The 1SG can then transport the rucksacks with the trains or assist with transporting heavier items so the platoon can move back to their rucksacks. Organizing the trains aids the 1SG in resupplying the company and equipping it for the fight.

fuel, food, and water during an exercise in Hawaii on 5 June 2019.

VIEW ORIGINAL

Establishing a packing list and issuing guidance will help 1SGs control their CRP. Having a strict packing list that is stored in accordance with an SOP will aid resupply operations, especially if time is a concern. Before distributing rucksacks, the 1SG should issue task, conditions, and standards to the platoon sergeant (PSG). This may be as simple as letting him or her know to keep the rucksacks until the next morning. This will give the platoon the opportunity to swap out dirty clothes, conduct hygiene, and access sleep gear. If there is a time constraint, the 1SG should issue a time hack along with the task to be completed. For example, remove chemical, biological, radiological, nuclear (CBRN) equipment and return the rucksacks in 15 minutes. When Soldiers receive their rucksack, they should know exactly where to reach to get out the items they need because there is not time to dump out a ruck in search of a required piece of equipment. Of course, all of this has to be done while security is maintained and in a location that the trains will not be decisively engaged. A well-organized load plan will aid in the distribution of equipment.

Establishing a load plan is essential for efficient resupply operations. Optimizing the space available in the vehicle package is critical. The trains will likely have Soldiers’ gear, ammunition, meals ready-to-eat (MREs), water cans, fuel cans, medical equipment, batteries, platoon equipment, and class IV materials just to name a few items. The items loaded in the trucks have to be organized in a way that casualties can be loaded if there are injured Soldiers. The 1SG should establish a plan and practice loading supplies prior to a mission. The resupply team should organize the trains in a way that allows it to distribute the most important equipment first. For example, after transitioning into the defense, the resupply team will need to hand out class IV items and AT weapons systems quickly. This will be hard to do if they are under cases of energy drinks. Creating speedballs will assist the 1SG in quickly distributing supplies.

Making Resupply Operations More Efficient

Speedballs are of vital importance when resupplying a large group of Soldiers. As resupply needs change in the field, PSGs should be proactive about sending up their LOGSTAT in accordance with the battalion’s SOP. Ordering the right equipment and packing important items ahead of time will assist the process. A speedball is simply a pre-packaged container that is easy to maneuver and organized with essential supplies. Soldiers can construct speedballs from many items, but duffel bags, aviator kit bags, and body bags all work well. Soldiers must ensure they waterproof the contents of the bag. The load must not exceed the Soldiers’ ability to transport the contents by foot. Ordering extra magazines will allow the 1SG to preload magazines and package them in 50 cal. ammo cans for quick distribution. The PSG can aid the process by collecting up empty magazines to exchange for the prefilled cans. The PSG should also collect dead batteries, batteries that need recharging, MRE trash, damaged equipment that needs repair, and other unneeded items so he or she can essentially swap a used speedball for a fresh one. This method simply requires each squad to carry an extra duffel bag. The PSG should also facilitate the process by identifying a resupply squad that will transport the supplies. When necessary, the resupply squad can make it easier to move the supplies by bringing Skedcos. The resupply squad must be able to move equipment while pulling security, but it should also have the ability to react to contact if necessary.

While the 1SG can streamline equipment distribution, water delivery can be more of a challenge.

A rifle platoon requires a lot of water during sustained LSCO. A quart of water weighs roughly two pounds. A normal light infantry platoon has an average of 40 Soldiers in it, with each carrying six quarts of water between their fighting load and sustainment load. This equates to 12 five-gallon water cans to resupply a platoon (total weight of 480 pounds). Multiply that across a company, and the 1SG can quickly end up with an LMTV full of water cans and no room for any other equipment. The 1SG can predict troop water consumption based off the expected work cycle and environmental considerations. Without a strategy, resupplying Soldiers with water can become time consuming and potentially have a negative impact on operations.

Delivering water to Soldiers is a complicated task if the 1SG fails to plan. The water buffalo carries the majority of water in the company trains. The problem is how to get water from the buffalo to the resupply squad efficiently. Water cans can fill a platoon at a time and then be refilled prior to delivering to the next platoon when using the tailgate method. A unit conducts the tailgate resupply method by driving the trains to each subordinate unit’s location and distributing supplies. When using the service-station method, the resupply squad can bring the platoon’s canteens in the duffel bags it is carrying to the CRP and fill them there. The 1SG will have to separate the resupply squads by time and space, as this method of resupply is tedious and time consuming. A limiting factor for this method of resupply is that Soldiers may not be able to move a platoon’s worth of water and equipment in a single trip. The 1SG can distribute water more efficiently by planning and ordering the right equipment.

With a solid plan and the correct equipment, the 1SG can resupply water quickly. Using two-and-a-half-gallon water cans can make it simpler for platoons to distribute large quantities of water across their resupply squad. Adding five-quart canteens to a speedball makes it easier to transport and subsequently distribute water. The key is to have enough to swap one for one so there are always some containers available in the company trains. Bulk Camelbacks, water filtration systems, bleach, iodine, and commercial off-the-shelf water purification systems for both individual and bulk water treatment are all viable options for cutting down water resupply frequency. After all, there is a reason that a key criterion for establishing a patrol base is that it is near a source of water. It is up to the 1SG to discern how to quickly get water from the company’s buffalo to the individual Soldier or provide equipment to cut down the need for constant water resupply.

Powering Radios in the Field

Another logistical challenge is keeping radios powered. Keeping radios functioning with charged batteries can become difficult during LSCO. Rifle companies carry numerous radios that require different batteries. Disposable batteries are expensive and difficult to keep in stock. This leaves rechargeable batteries as the practical option. The issue with rechargeable batteries is power generation for recharging.

Most companies are not equipped with portable generators. Battery recharging stations typically require a 110- volt outlet. Solar panels and hand-crank generators are an option but take too long to recharge batteries, may require the unit to be stationary, and are generally impractical for charging large quantities of batteries. That leaves a company with two options: a power converter run off the vehicle’s battery or a portable generator. A portable generator will allow the company to run several charging stations at a time. The major drawback is the company will have to add gasoline to its sustainment plan. Additionally, generators are loud. If the company command post (CP) can rotate batteries, a power converter and a generator should keep the company’s radios powered. It is up to the resupply team to ensure it adds fresh batteries to speedballs and returns dead batteries to the recharging station. With the company resupplied, the 1SGs can turn their attention to CASEVAC and MEDEVAC operations.

CASEVAC and MEDEVAC Operations

The 1SG is a driving force in CASEVAC and MEDEVAC operations. We have all heard the phrase “no plan survives contact with the enemy.” The company will have to evacuate Soldiers from the battlefield due to enemy contact, disease, or injury. It is up to the 1SG and his or her medical team to determine the precedence of the patients and facilitate their movement to the appropriate level of treatment. The 1SG must have planned, coordinated, and disseminated company casualty collection points (CCPs).

By matching CCPs to the maneuver plan, the 1SG can often cut down on the time it takes for Soldiers to receive treatment. While the platoons are concentrating on care under fire, tactical field care, and triaging casualties in the platoon CCP, the 1SG must find a way to get the casualties off the battlefield. Depending on the nature of the fight and its proximity to the enemy, it is often unfeasible to bring MEDEVAC assets to the point of injury. By clearly painting the picture during planning and accounting for conditions on the ground, the 1SG can assist the PSGs with understanding when they will be required to move casualties to the company CCP and when the 1SG can move forward to load casualties. Both company and platoon CCPs should support the larger maneuver plan. The company should avoid using rolling CCPs. Tough realistic training should incorporate CASEVAC and MEDEVAC procedures into key collective and mission-essential task (MET) training.

MEDEVAC operations should be routine business for maneuver forces. The triage of casualties, use of aid and litter teams, and packaging of casualties are all essential elements of successful medical evacuation. First-aid training is vital, but knowing when to conduct first aid is also important. Many Soldiers will stop fighting to treat injured Soldiers. It is important to finish the fight and secure the area before going into medical treatment that goes beyond care under fire. With sufficient training, units will be able to save lives on the battlefield and then focus on moving casualties to higher levels of care.

Another critical component to successful medical evacuation is securing key weapons systems and gear. While it is important to evacuate casualties quickly, it is essential for the fighting element to maintain needed equipment. Units often evacuate casualties with all of their equipment, and later the element discovers that it needs equipment that was evacuated with the patient. Units typically use a status card to mitigate this issue. My unit uses an expanded air assault bump card as our SOP. Soldiers carry three laminated index cards that have their battle roster number, blood type, and element on them. On the back and written in marker, Soldiers list their sensitive items and any mission-essential equipment they are carrying. Leaders take the cards at each stage of the medical evacuation process so they can maintain accountability of Soldiers and their sensitive items. Prior to the evacuation, the leader on the ground uses the card to identify and redistribute key and essential equipment. The formation will still need items such as radios, AT rounds, machine-gun ammo, laser designators, and other like items. When the aid and litter team has removed mission-essential equipment and packaged the Soldier, the 1SG is ready to move the casualty to the MEDEVAC site or the ambulance exchange point (AXP).

The 1SG is responsible for moving casualties from the company CCP to the AXP, MAS, FAS, or to a MEDEVAC landing zone (LZ). It is imperative the 1SG understands where the battalion has established these elements and where adjacent units have their medical assets as well. The 1SG can capture these locations using graphics and an overlay. Depending on the enemy situation and the element’s proximity to the various medical assets, the 1SG may need to skip a lower echelon of care to expedite the process. If going to the MAS or FAS, the 1SG will need to coordinate with the HHC 1SG at the CTCP to facilitate the hand off of casualties.

Evacuating Remains and Receiving New Soldiers

Despite our best efforts, Soldiers will die on the battlefield, and the 1SG must have a plan to evacuate their remains. Transporting the remains of deceased Soldiers is a daunting task. Training LSCO at the Combat Training Centers (CTCs) has unveiled a gap in our training and doctrine. What should units do when they have a platoon of deceased Soldiers? While the Army figures out the way forward, rotational units have to figure out the best procedures for solving the problem. There are some methods that can help. The unit should not move deceased and living Soldiers together. Additionally, the deceased are the lowest level of precedence for evacuation. Leaders should apply prudent judgment when assigning aid and litter teams. When possible, friends of the deceased and direct supervisors should not be the Soldiers that receive the task. In a combat environment and when practical, the company may need to request the Chaplain to speak to Soldiers. During LSCO, it may not be possible for Soldiers to have access to other mental health providers until later in the fight. Finally, the company will have to move the remains to the MAS or the CTCP for further transportation to the MACP. Eventually, the company will receive replacement Soldiers or attachments from other elements.

Once the CTCP notifies the 1SG that new Soldiers have arrived at the CTCP, the 1SG will have to coordinate to have the Soldiers moved to the company CP. The 1SG may need to lead the convoy from the LRP to the CP. Other times, the 1SG will have to use the company trains to move the Soldiers. After their arrival, it is up to the 1SG to assign replacements to the appropriate elements, concentrating on filling the shortest platoons and re-manning key weapons systems. Leaders at all levels should make a concerted effort to conduct rehearsals when tactically appropriate so the newly arrived Soldiers can learn the unit’s SOPs and tactics, techniques, and procedures (TTPs). If the higher headquarters moves the formation to a rear area, leaders should prioritize training to allow the Soldiers to improve.

Conclusion

During LSCO, 1SGs are a combat multiplier if they are able to plan, synchronize, and efficiently conduct sustainment operations. It is imperative 1SGs understand how the brigade arrays and fights the sustainment enterprise. This will allow them to identify and lubricate friction. By involving themselves early in the planning process, 1SGs can aid sustainment by phase, enabling movement, maneuver, and defensive tasks. Effective use of the company trains through load planning, packing list SOPs, and speedballs will preserve Soldiers’ endurance and allow for the quick distribution of supplies. Carefully planning CASEVAC and MEDEVAC operations, as well as understanding the location of medical assets, will ensure timely treatment of injured Soldiers. The 1SG’s management of sustainment operations through the company trains and the CTCP is a critical component of successful LSCO.

Notes

1 Paul Scharre, “The U.S. Military Must Lighten Warfighters’ Loads,” Defense One, 30 September 2018. Accessed

from https://www.defenseone.com/ideas/2018/09/us-military-must-lighten-warfighters-loads/151673/.

Social Sharing