Intro: Importance of Sustainment Synchronization

Sustainment requires simultaneous and continuous synchronization at all echelons of command. The sustainment warfighting function can be both complex and complicated when not handled appropriately. Sustainment warfighting requires a holistic and balanced viewpoint at all echelons for a unit to be successful. Looking at sustainment throughout the years, specifically property accountability, there are multiple challenges and lack of synchronization at the company supply level. Company supply rooms must have trained supply personnel who stay nested with each other on day-to-day responsibilities to be successful. Supply teams must understand and share a balance of roles and responsibilities. To better set conditions for success, units need to invest time in developing company supply teams with the appropriate training and certification/ qualification. Sustainment team certification establishes a common language and understanding of standards allowing commands to understand the risk they are assuming in their supply rooms.

Supply Team Certification

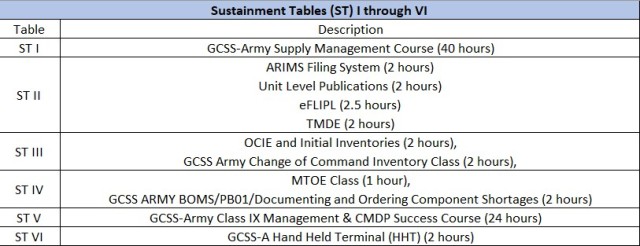

A company supply team will typically consist of a Company Commander, Supply sergeant, Supply clerk and Executive Officer/ Supply Officer. Given that the Army is Commander centric, and that Command Supply Discipline Program (CSDP) is the Commander’s program, a Commander must stay involved with daily supply transactions to enforce appropriate supply measures. The Commander and his small team of Soldiers can be fully functional if all Soldiers get the appropriate training and know their roles and responsibilities. Considering that the workload of a supply team can sometimes be overwhelming each supply representative must be diligently involved with their day-to-day supply contributions consistently. A Supply team certification model similar to an Integrated Weapons Training Strategy (IWTS) certification concept could be extremely beneficial to company supply teams. IWTS tables build relationships, increase maneuver understanding of how to provide sound guidance and raise understanding of the capabilities and limitations of maneuver unit systems. “Fundamental Soldier and military occupational specialty specific skills serve as the foundation of IWTS and must not be overlooked. Soldiers, crews, teams, squads, platoons, companies, and battalions achieve the highest level of proficiency when building upon mastery of those foundational skills”, (TC3-20, 2019). A similar Supply team certification concept like that of IWTS would help synchronize needed training for supply teams and provide a shared experience for Soldiers to be better involved as sustainment leaders. Though some might think the notion of supply team certification is bit unconventional, it is not too farfetched to lean towards the unusual process of table certification for supply teams, especially given the fact that supply teams will have more supply transactions in the future modernization efforts, like store front, changing the way sustainment does business. Supply team certification would further prepare supply teams for success by giving them the experience they would need for future supply transactions. So, what does a supply team certification table look like? My theory is that it would incorporate all the essential elements of supply. A supply team would need to understand the basic knowledge of sustainment within their unit to be successful. This concept would include the knowledge, training, and understanding in cyclic inventories, Change of Command (CoC) inventories, lateral transfers, Total Equipment Management Strategy (TEMS), and maintenance operations. I recommend a two-week (81.5 hours) certification block consisting of the following supply course sustainment tables where supply teams go to get trained and certified:

Supply Team Certification Training and Resourcing

Supply Team certification is not a bridge too far, given the fact Army had a similar proficiency program concept in the late 70s called the Skill Qualification Test (SQT). It might not be too hard to even fathom a similar proficiency MOS testing concept extending to all the other MOSs across the Army also. Professional Military Education (PME) is not something that should be taken lightly, especially if we intend on having leaders lead effectively at the speed of war. Though resourcing may have hurt previous program concepts, resourcing for supply certification training would come from the BNs to the companys with assistance from COMET team reps. COMET team reps would conduct training with BN S4s doing the final certification after training is complete with hands-on vignette testing consisting of supply reports, FLIPLs, ARIMs, and normal supply transactions for certification test out. A more internalized resource concept might prove to be a move in the right direction.

Final thoughts and considerations

By focusing on synchronization, we can change the cultural misunderstandings at the company supply level. Synchronization at all echelons is critical when understanding required training. I recommend that company supply teams receive training immediately upon arriving at their unit and are certified immediately following their arrival with Supply team certifications. If a Soldier fails certification they retrain and if they fail again the argument should be made that they maybe reclass or be flagged. Also given the frequency of personnel changes, supply teams need recertification annually. The consistency of required training on a routine basis ensures the supply synchronization needed for unit sustainment success. Furthermore, it’s time to ask the hard question, if Soldiers cannot demonstrate proficiency in their MOS, especially with something as extremely as technical as sustainment, then maybe Soldiers need more self-development, or the Army needs a stronger stance on PME certifications.

Social Sharing