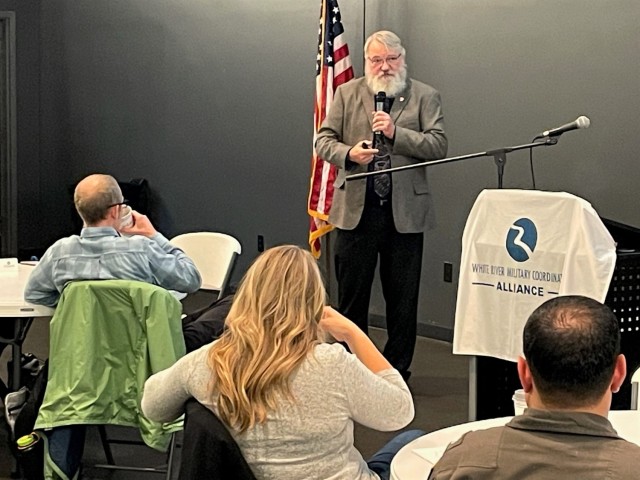

CRANE NAVAL SUPPORT ACTIVITY, Indiana – “One of our primary missions at Crane Army Ammunition Activity is demilitarization of conventional munitions and it falls upon us to execute all methods of demilitarization in a safe and environmentally responsible manner,” stated Paul Allswede, Director, Crane Army Ammunition’s Manufacturing and Engineering Directorate. The comment was made during a meeting of the White River Military Coordination Alliance held May 17 in Bedford, Indiana.

“This is part of our effort to provide information to the surrounding communities about what we do and how we do it,” he said, adding, “and, we live here, too, and we take being good stewards of the environment to heart.”

Allswede discussed reasons for demilitarizing munitions as one of the core competencies at Crane Army, in addition to various types of munitions production, and the receipt, inspection, storage and distribution of munitions.

In addition to manufacturing, he said, “We have the capacity to store over 650,000 tons of conventional munitions. Safety is the primary driver when we handle and manage munitions.” He noted protocols such as minimum distances between magazines, controlling explosive weight limits inside magazines, and segregating munitions by compatibly groups to minimize risk.

“Approximately forty percent of what’s stored is unserviceable, obsolete, or no longer safe for storage and has to be demilitarized via open detonation, open burning, or closed disposal methods such as thermal treatment, or chemical conversion,” he told the audience of community members and local officials.

Providing a general demilitarization overview, Allswede stated, “Think of the demilitarization process as reverse manufacturing. In demilitarization we take one part and make many versus taking many parts and making one in manufacturing. Then, it becomes a matter of safe and environmentally compliant waste stream management.”

He further explained the various demilitarization methods used. “Energetics are typically demilitarized using open detonation where explosive shots which are designed to blow down, not up, and buried and covered with earth to dampen the explosive output. Shot sizes will vary depending upon temperature and foliage. When temperatures are at or below 45-degrees Fahrenheit, air density changes and loss of foliage causes a loss of natural noise dampening making the detonation effects more pronounced. We want to be good neighbors and to minimize shaking things up, so we use half shots.”

“Open burning is another demilitarization method in which items, such as propellant, is placed onto large burn pans, ignited, and consumed by open flame.”

“Thermal treatment,” Allswede continued, “is used to demilitarize small-cartridge ammunition and to chemically convert red and white phosphorus into phosphoric acid. Small cartridge ammunition traverses a high temperature rotating retort which causes ammunition to rupture, or pop, expending its energetic as it travels through the retort. We also use a larger, high-temperature retort to chemically convert red and white phosphorus into phosphoric acid. The phosphorus containing item is punctured and auto ignites, then traverses a much larger high temperature retort to enable complete outgassing of the phosphorus and using reverse draw and water quenching creates phosphoric acid. Both thermal treatment processes are closed system meaning they have pollution abatement systems attached resulting in zero emissions.”

“We’re an avid recycler,” he added. “All recoverable scrap metal produced during demilitarization processes is turned in for recycling. Additionally, the phosphoric acid produced from the white and red phosphorus chemical conversion is used as a fertilizer component. So, we are literally taking munitions and growing corn.”

“We monitor, track, and record all our demilitarization output,” Allswede said. “We are regulated by, and remain compliant with, four governing environmental authorities; the Environmental Protection Agency, Indiana Department of Environmental Management, Army Environmental regulations and, because we are a tenant on a Navy Installation, Navy Environmental regulations. We stay well within permitted emission limits, and we can track down to the ounce, gram, or dram of materials such as cadmium, lead, or other heavy metals, contained in each individual munition destroyed.”

Allswede conclude by saying “We will remain good stewards of the environment and we actively seek out, assess, and transition to greener technologies when appropriate.”

Crane Army Ammunition Activity produces and provides conventional munitions in support of U.S. Army and Joint Force readiness. It is part of the Joint Munitions Command and the U.S. Army Materiel Command, which include arsenals, depots, activities and ammunition plants. Established Oct. 1977, it is located on Naval Support Activity Crane.

Social Sharing