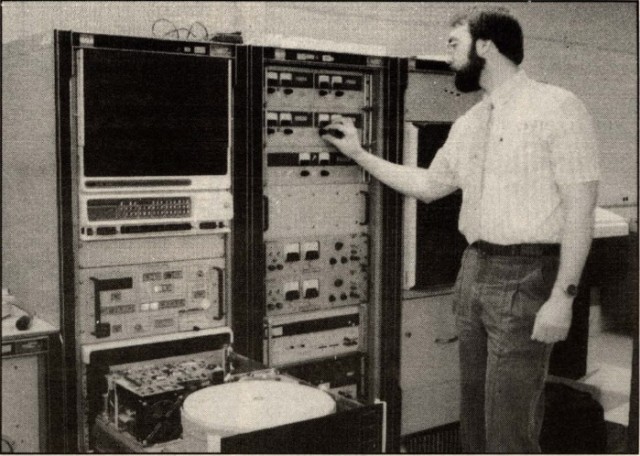

For more than six decades, artisans at Tobyhanna Army Depot (TYAD) have been at the forefront of repairing and employing automatic test equipment (ATE)to diagnose and test military equipment. That mission continues today, underscoring Tobyhanna’s commitment to supporting the joint warfighters of the past, present and future.

ATE refers to test hardware with its own operating system software that enables users to assess the functionality of a weapons system, detect quality issues, and ensure applied corrective actions have been successful. The use of ATE benefits the depot in a variety of ways, from increasing the quality of repairs to reducing internal turnaround times and beyond.

Historical records show a huge surge in ATE at Tobyhanna in the early 2000s. The increased need for ATE came after a significant amount of new workload arrived at the depot; the workload transitioned to TYAD after a Base Realignment and Closure Commission, which was focused on divesting excess capacity and property within the Department of Defense.

TYAD’s ATE repair workload has represented one of its most constant but always evolving initiatives. For example, the Electronic Quality Assurance Test Equipment (also called the EQUATE system) has been a TYAD mission for over three decades. Used by servicemembers worldwide, the EQUATE is a test station used for multiple types of testing for wire assemblies in support of counterfire radar missions.

Investments into ATE programs like the EQUATE are particularly fruitful for the depot because the positive results are two-pronged. In repairing, maintaining, and sustaining ATE, TYAD enjoys consistent workload that directly impacts readiness and saves lives. The maintenance of these systems also allows the depot to apply the testing capabilities of the ATE to other products depot artisans are preparing for our nation’s warfighters.

The benefits of ATE utilization are many. If one were to walk through the plethora of production floor areas at TYAD today, several instruments used to perform tests on workload both old and new can be seen. These instruments help to ensure every asset being provided to our nation’s warfighters is up to the lofty Tobyhanna standard through increased efficiency and accuracy.

Efficiency is the name of the game when it comes to ATE. It will rack up multiple instruments and put it under PC control, eliminating the possibility of human error and centralizing several tests under one umbrella. It is capable of performing various tests at once even if the systems aren't exactly the same, reducing the time it takes to ensure compliance across multiple workloads.

In order to mitigate unforeseen issues, ATE can also be used to proactively ensure systems are functioning the way they are intended. This offers artisans at TYAD a huge boost in efficiency as they can be certain no time is being wasted by assembling something that has issues.

Electronics Engineer David Zahorsky said the use of ATE helps alleviate the load on an employee’s shoulders.

“In some shops, you may see individual instruments used to test specific things. For example, say you need to make a voltage measurement and you need to manually input a lot of information. The beauty of automatic test equipment is that you can automate all of those tests,” said Zahorsky. “For the purpose of completing an entire test document, it reduces the burden on technician personnel to have to make those individual tests. It also reduces mistakes that could potentially be made by missing a test or something like reading an instrument.”

ATE utilization and the development of test program sets (TPS) can also be used as a means to see around corners when navigating systems and preparing to take on new workload. By frequently running self-test alignments the individuals working on the production floor can hit the ground running and start properly testing the technological components necessary for the equipment to function correctly.

Just as assets change to meet the needs of the warfighter on an ever-evolving battlefield, so must the test procedures evolve. Combined hands-on and software repair and troubleshooting works in synergy with proactive TPS development and transition to ensure TYAD remains on the cutting edge into the future.

TPS development is a key activity during the transition to sustainment for military assets, streamlining the repair process. Test Engineering Branch Chief Matthew Rhoades and his team build test programs to support new assets and workload. Four TPSs are being developed during the onboarding of the MQ-9 Reaper workload, according to Rhoades.

“The TPSs developed in conjunction with public-private partnerships with L3Harris and General Atomics enable TYAD’s electronics personnel to screen LRUs at the beginning of the process to identify where the asset requires repair. Once repair is complete, assets are tested to validate the repair, ensuring the warfighter receives a quality product – every time.”

While Rhoades and his team work to either build new TPSs or rehost them on new ATE, Production Equipment Branch Chief Wayne Swire and his team keep equipment up and running. Swire said the key to sustained ATE success for Tobyhanna lies in the present.

“The key is having the capability in-house. By adding to our capabilities in the present, TYAD best positions itself to support warfighters on an evolving battlefield,” said Swire.

In many ways, the future of ATE has already arrived at TYAD. The last couple of years have been marked by transition from legacy and sustainment systems like the EQUATE to new systems like the Air Force-standard Versatile Diagnostic Automatic Test Station (VDATS) and the Army-standard Next Generation Automated Test System (NGATS). While VDATSs have been at TYAD for a decade, the depot is scheduled to receive its first full rate production NGATSs this year. The VDATS has supported the aforementioned MQ-9 Reaper and depot personnel are ready to hit the ground running once the NGATS arrives to provide TPS capability for the AN/TPQ-53 Radar System.

The utilization of ATE and the development of TPSs in conjunction with the precision and dedication of depot artisans ensures TYAD will continue to deliver on that mission now and into the future.

The repair, sustainment, and development of ATE and TPSs directly aligns with Tobyhanna’s long-range strategic plan, TOBY2035, which has four focus areas: Invest in Our People, C5ISR Readiness, Shape the Future and Strategic Communications. TOBY2035 aims to posture the depot for success in the coming years as the Department of Defense's premier worldwide C5ISR readiness provider.

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for command, control, communications, computers, cyber, intelligence, surveillance and reconnaissance (C5ISR) systems across the Department of Defense. Tobyhanna’s Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C5ISR provider of choice for all branches of the Armed Forces and industry partners.

Tobyhanna’s unparalleled capabilities include full-spectrum logistics support for sustainment, overhaul and repair, fabrication and manufacturing, engineering design and development, systems integration, post production software support, technology insertion, modification, foreign military sales and global field support to our joint warfighters.

About 3,300 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania. Tobyhanna Army Depot is part of the U.S. Army CECOM. Headquartered at Aberdeen Proving Ground, Maryland, the command’s mission is to empower the Soldier with winning C5ISR capabilities.

Social Sharing