TOBYHANNA ARMY DEPOT, Pa. - Employees in one of Tobyhanna's industrial shops have worked for five years without any recordable injuries.

The Electrical Overhaul Support Branch's proactive safety program outlines current guidance and enforces training to keep employees out of harm's way.

"For an industrial area to go five years without a recordable injury is a testament to the employees' commitment to safety," said Russel Dunkelberger, Safety Division chief. "This type of accomplishment does not happen 'by accident'. This is not just a safety accomplishment; it is a display of employees' ownership in Lean and 6S principles as well as Army values."

The Safety Division is part of the Industrial Risk Management Directorate.

Generally, an injury or illness is considered recordable if it occurs in the workplace and results in: death, days away from work, restricted work or transfer to another job, medical treatment beyond first aid, or loss of consciousness.

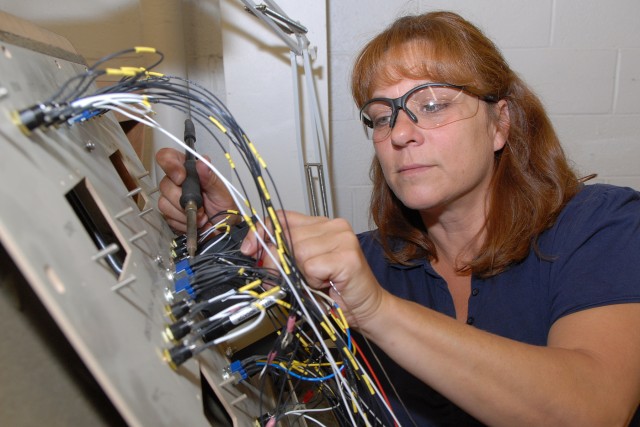

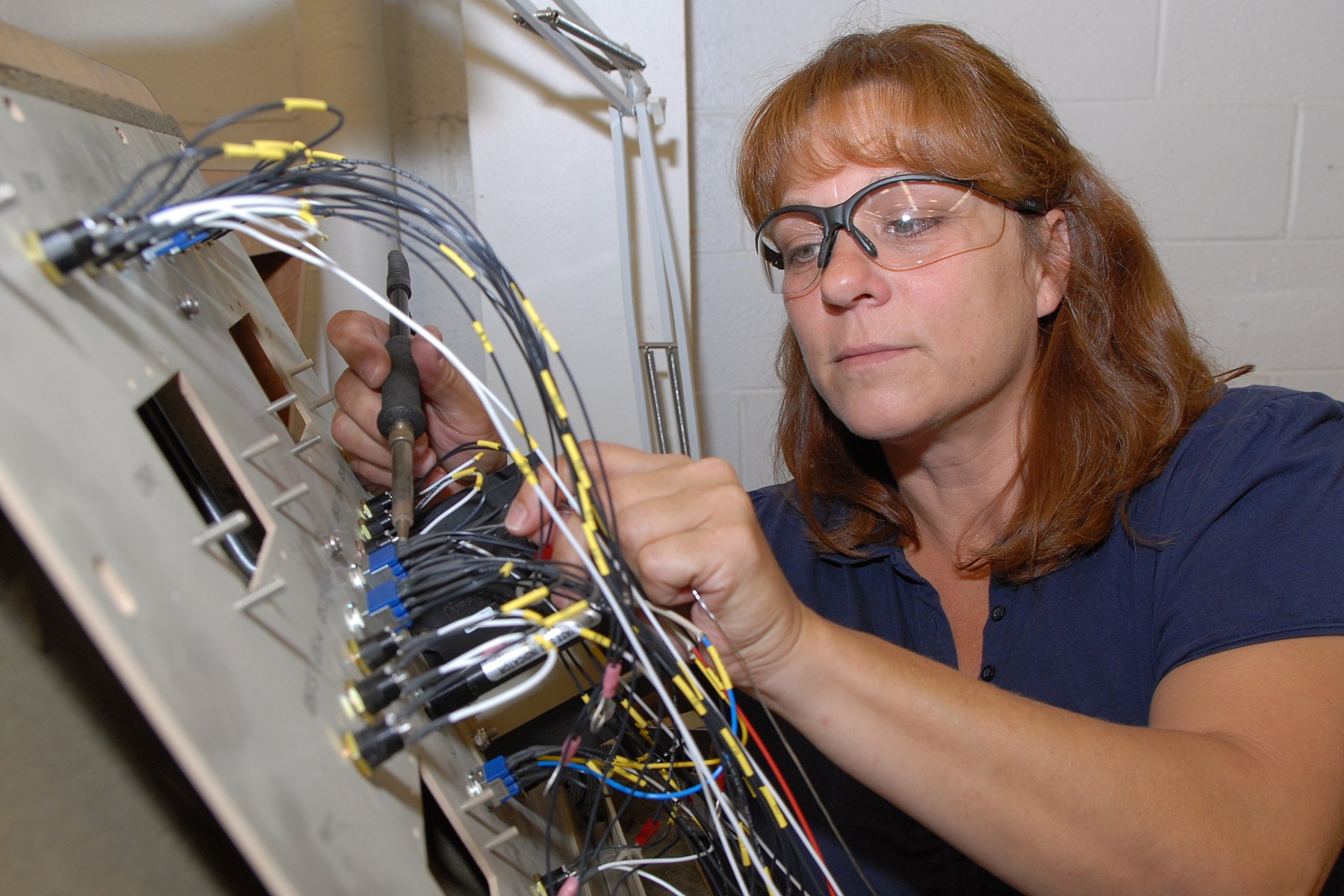

There are 42 people who work in the Systems Integration and Support (SIS) Directorate branch, performing electrical overhaul on various shelters and vans. Their tools of the trade include drills, crimping machines and hand tools.

"It's a team effort," said Steven Mikitka, branch chief, explaining that 25 percent of the cost center's work is accomplished in other shops on the depot. Members of the branch operate a production line in Building 3, the Tactical End Item Repair Facility (TEIRF) and Building 1B, Bay 6.

"Safety is an important part of our daily routine," said Ann Bell, electronics worker. "Not just for ourselves, but all those around us."

The branch complies with safety regulations and program requirements.

For example, employees are required to complete training about the wear of personal protective equipment (PPE) and procedures for working around tools, electricity and chemicals. Continuous training also teaches the importance of keeping food and drinks away from work areas, and not wearing loose clothing, ties, jewelry and metallic devices.

"I'm very proud of the employees," Mikitka said. "They make safety a priority day after day." He attributes the branch's success to the use of various safety tools, meetings and rewards programs.

"I schedule movies every couple of weeks, circulate the Safety Gram (published by the Safety Division), and post items on the bulletin board," said William Tegethoff, electrical worker and safety star point. The branch also meets once a week to discuss safety topics.

"It wasn't luck that helped us reach this milestone," Tegethoff said. "It was skill."

Employees in the organization rely on each other and their training to stay safe.

Electronics workers Charlie Keller and Jim Cotillo cite the weekly safety tips, and proper care and wear of PPE as key components to keeping employees from getting hurt. Sarah Gomez, a student trainee, agrees. She also remarked that safety training helps increase her awareness of the workplace environment.

"Safety is about common sense and not taking unnecessary risks," said Ed Emelett, electrical worker.

"Safety is a key focus area for the directorate because of the potential for injury as a result of our industrial support mission," said Terry Hora, SIS director.

"The directorate is very proud of the safety record of the Electrical Overhaul and Support Branch," Hora said. "This achievement reflects on the hard work and dedication of the employees in ensuring that their work environment is safe."

Tobyhanna Army Depot is the Defense Department's largest center for the repair, overhaul and fabrication of a wide variety of electronics systems and components, from tactical field radios to the ground terminals for the defense satellite communications network. Tobyhanna's missions support all branches of the Armed Forces.

About 5,600 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army CECOM Life Cycle Management Command. Headquartered at Fort Monmouth, N.J., the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing