FORT DETRICK, Md. – When Ethan Quist was a child, he liked to build things using LEGO and other construction toys. In middle school, he discovered that he also enjoyed math and science. During his senior year in high school, he took a computer science class that challenged and excited him. But by the time he graduated, those various skills and interests had yet to coalesce into a singular vision for his future.

“It really wasn't until I was filling out college applications that I finally saw computer engineering listed as a degree option and realized that maybe it could be a path forward for myself,” recalls Quist, who works at the U.S. Army Medical Research and Development Command’s Telemedicine and Advanced Technology Research Center. “Without really knowing what I would be getting into, I just decided to make the leap. And then as I was taking those courses, I realized that the work was actually stimulating the same part of my brain that enjoyed building LEGOs as a kid.”

Today, as the deputy functional area lead for TATRC’s Medical Robotic and Autonomous Systems Division, Quist gets to put all those skills to work every day building and testing robots that will help save the lives of people in danger.

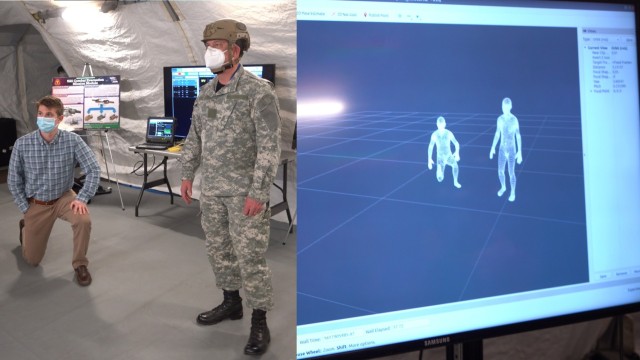

One of the systems that Quist is working on is a drone that can fly over a battlefield and scan Warfighters with cameras to see if they are injured. The drone, called the Areté Human Emergency Analysis and Determination system, uses sophisticated computer algorithms developed by Quist’s team to detect vital signs like heart rate and respiration, and then transmit that information to medics who can move in to rescue the injured Warfighter. MedRAS is currently working with Areté, which developed the drone’s sensors, to test the system in the field.

“We're working at the cutting edge of what this technology is capable of,” says Quist. “We're trying to detect people who are wearing camouflage and who may be covered in dirt or rubble, so they're hard to spot.”

Quist says it’s rewarding to know that the AHEAD drone could someday save not only the lives of injured Warfighters, but also the medics who would otherwise have to conduct those assessments under fire.

Another robotic system that Quist’s team is working on, Autonomous Casualty Extraction, will someday be able to roll up to an injured Warfighter and, using two robot arms controlled by artificial intelligence, grasp and reposition the injured Soldier and drag them away to safety. First, however, MedRAS has to successfully train a robot arm to recognize human limbs and calculate how to position them to prevent injury when the person is being lifted into the vehicle.

“We are working with doctors at the University of California San Diego to teach the robot how human shoulders, elbows, knees and hips move,” explains Quist. “It's a cross between robotics, engineering and biomechanics. That kind of collaboration across disciplines is common for a lot of the projects we work with.”

TATRC’s Telesurgical Robotic Operative Network, nicknamed TRON, is a prototype system that combines virtual reality with robotics in a way that will enable a surgeon to operate on a patient located far away. A VR headset lets the surgeon see a live video of the operating table, and hand controllers allow them to manipulate a pair of robot hands to perform delicate surgical tasks. Like many other MedRAS projects, TRON uses a commercially available robot, SRI International’s Taurus-M, operated by software developed by the TRON research team.

“It feels a lot like a video game,” says Quist of operating the TRON robot remotely. “You're fully immersed in a virtual operating room, looking through the robot’s camera eyes and moving its hands. After a while, it starts to feel natural. It is really cool!”

During testing, Quist’s team discovered that the further apart the surgeon and the patient are, the longer it takes the robot hands to respond to the surgeon’s motion. They are experimenting with using AI to help fill that gap, by allowing the robot to anticipate what the surgeon will do next. This means training the robot to perform a wide range of surgical tasks, and to know when – and when not – to perform them.

“When you're doing robotic surgery, you don't want to make mistakes,” says Quist.

These cutting-edge projects are just a few of the ways that MedRAS supports TATRC’s mission of finding ways for data, humans and machines to work together to provide better care for our wounded Warfighters – often in hazardous conditions where doctors and medics themselves would be in danger. And there are many groups like TATRC throughout the Army where people with science, technology, engineering and math degrees can find challenging and exciting problems to solve every day. Over 64,000 Soldiers with engineer specialties serve throughout the Army’s active, National Guard and reserve components, including 38,000 in the famous Army Corps of Engineers. The Army offers paid internships, competitive benefits, international assignments, student loan repayment and continual learning opportunities.

Quist has advice to offer young students who are considering a STEM career.

“Have a curious mind and keep asking questions about ‘why’ and ‘how,’” he says. “When you walk by everyday items in your life, keep wondering, ‘How does this work?’ You can look at your cell phone and ask yourself, ‘How does the text message actually send, and how does it get displayed on the screen?’ And pretty soon you'll be going down rabbit holes looking into radio transmissions and RGB pixel displays. If you can end up finding enjoyment and diving into specific rabbit holes, then you'll end up enjoying 80% of what it takes to be an engineer.”

And the other 20%?

“Discipline and innovation,” answers Quist. “It’s not enough to just have knowledge, you have to apply it in ways that make something actually work. And that often means being creative, thinking of new solutions and trying things that you haven’t tried before.”

Quist says that for him, the most rewarding part of being an engineer is the pride and confidence he feels when he succeeds in solving a complex problem.

“Pride and confidence will set any engineer up for success in a lot of other aspects of life,” says Quist. “The confidence you get from an engineering degree and career lets you know that you're up for any task in front of you.”

Social Sharing