REDSTONE ARSENAL, Ala. — After the Chief of Staff of the Army charged AMC with leading efforts to deliver ready combat formations, the Army’s senior sustainer, Gen. Charles Hamilton, delivered his vision for the future of the sustainment enterprise.

Army Materiel Command will modernize the way it looks at delivering sustainment and materiel readiness to meet the needs of a multi-domain operations-capable and ready joint force, he said during AMC Commanders Forum in September.

“Sustainment is about warfighting — period,” said Hamilton.

“We’re modernizing our training, our processes, our skillsets, and our infrastructure to support and sustain next-generation systems. Advancements in Sensor to Shooter to Sustainer capabilities will enable us to transition from reactive logistics to what we call predictive logistics,” he said.

From the Army’s Organic Industrial Base depots and facilities to ports in the U.S. and Europe, to utilizing emerging data capabilities and transforming Army installations across services and infrastructure while strategically positioning the military for success in global theaters, AMC and its major subordinate commands have showcased a series of remarkable Army sustainment accomplishments across various fronts this year.

Soldier, Civilian and Family Readiness

Recognizing that a resilient and prepared force is a key to readiness, the command implemented innovative programs and initiatives supporting quality of life for Soldiers, families and civilians.

Over the year, both the Army and the privatized companies who manage housing on installations continued to invest in military housing with additional plans for 2,400 new homes and 18,600 renovated homes by fiscal year 2025 across the Army portfolio. The Army is also investing $1.1 billion per year to improve barracks through FY29.

In October, Presidio of Monterey, California, opened new, energy efficient homes that feature solar panels, Energy Star appliances, LED lighting and water-efficient fixtures. The houses are expected to be 30% more energy efficient than the average home.

“These investments directly affect the quality of life of Soldiers and families on Army installations and reflects our commitment to People — the Army’s top priority,” said Jordan Matthews, AMC G-4 facilities division chief.

To further support Soldiers, AMC is driving a renewed strategy to build a modernized food ecosystem that ensures Soldiers have access to affordable, healthy food options, with convenient and flexible feeding alternatives for Soldiers, such as expanded use of culinary outposts like food trucks and 24-hour self-service kiosks.

“It’s time to revolutionize the Army’s food service. We need to get after the modernization and change needed to provide a comprehensive and holistic improvement to how we provide food service across the Army,” said Lt. Gen. Chris Mohan, AMC deputy commanding general.

The Army also completed the renaming of nine new installations that reflect the courage, values, sacrifices and diversity of military men and women ahead of the scheduled completion date of January 2024.

Posture the Joint Strategic Support Area

An integral part of delivering ready combat formations is posturing the Joint Strategic Support Area. This effort encompasses mobilization and deployment as AMC delivers installations capable of supporting current and evolving readiness and power projection requirements at the speed of war in a contested environment.

The ability to maintain the flow of resources, supplies and equipment from the Joint Strategic Support Area to the tactical point of contact is a critical determinant of victory in modern warfare and large-scale combat operations.

Transportation offices, depots, arsenals, activities, plants, ports and installation railheads, roads and airfields key to the nation’s power projection capabilities are being modernized to support the joint force.

Positioning the Organic and Defense Industrial Base

Recognizing the importance of a robust and adaptable manufacturing and procurement process, the command has fostered innovation, streamlined acquisition and cultivated partnerships with industry leaders.

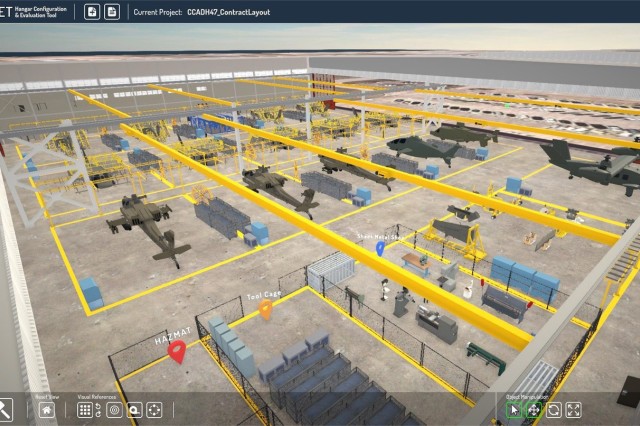

This year marked the official start of AMC’s 15-year OIB Modernization Implementation Plan. The $18.1 billion effort will modernize facilities, processes, and the workforce to bring the OIB into the 21st century, infuse industry best practices and refine human capital management structures to maximize the skills and capabilities of the workforce.

“The Army is driving the OIB Modernization plan,” said Marion Whicker, AMC executive deputy to the commanding general. “The Army had a plan, and we were able to demonstrate that we were shovel ready, so when the DoD accelerated modernization efforts, the Army’s OIB was ready.”

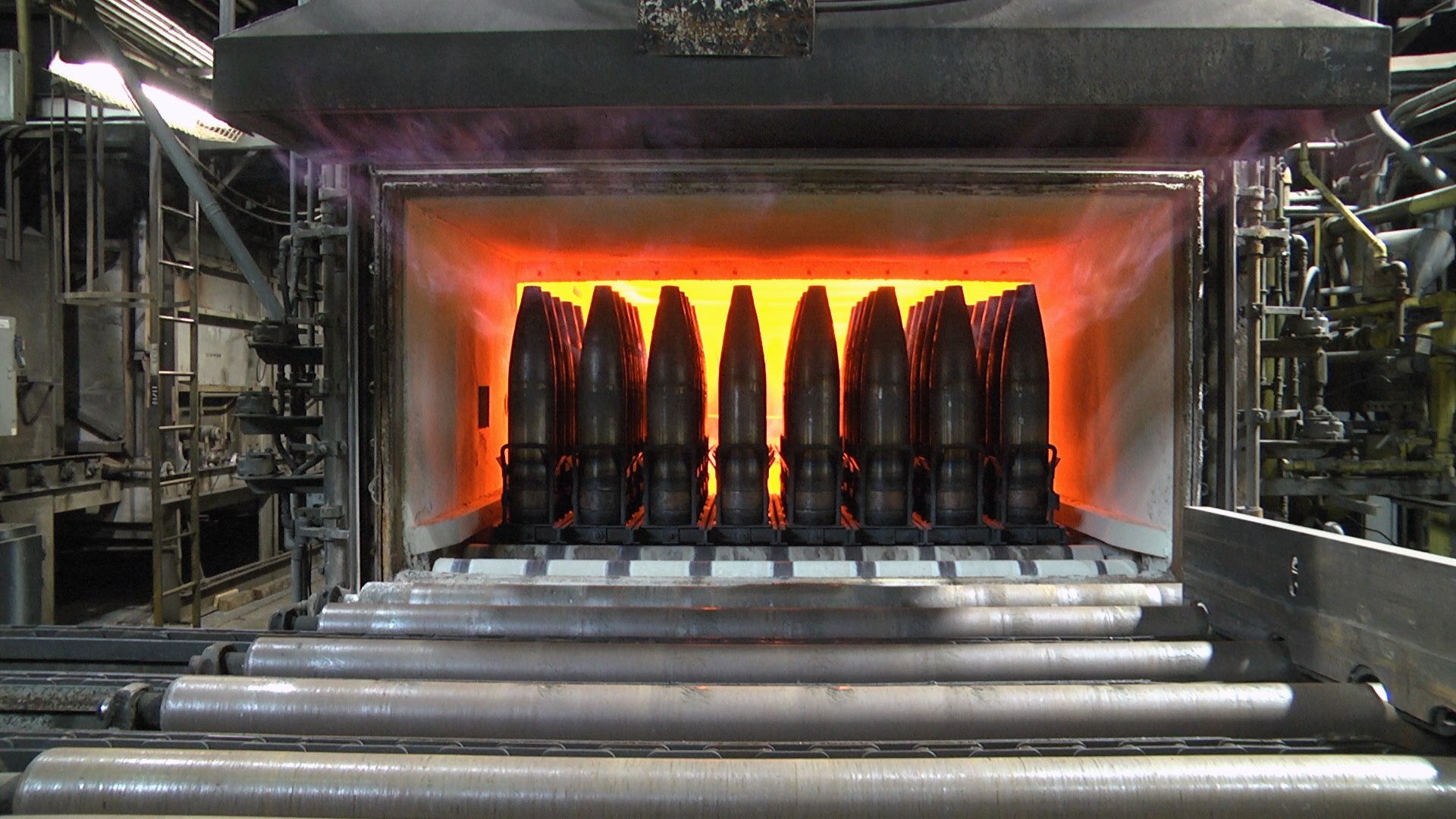

The OIB also showcased its criticality in sustaining operations in Eastern Europe. Some of the modernization projects started ahead of the planned FY24 start due to additional funding the Army received connected to ammunition production, including efforts to accelerate 155 mm production. With those funds, the Army’s artillery production doubled in the last year with the service currently producing 28,000 155 mm howitzer rounds a month.

Preparing the Indo-Pacific and European Theaters

AMC has strategically positioned logistics, prepositioned stocks and transportation assets in the Indo-Pacific and European theaters to enhance the agility and responsiveness of the joint force.

“Critical to preparing the theater is prepositioning people, munitions and equipment, including combat enablers such as sustainment, to provide the right effects at speed and scale,” Hamilton said.

This year, AMC provided vital sustainment support to Talisman Sabre 23, one of the largest exercises in the Indo-Pacific theater, validating the command’s mission to get troops and equipment to the fight — rapidly and efficiently — from its installations to the tactical edge in a realistic training scenario.

During TS23, U.S. Army Pacific, in coordination with AMC, conducted theater entry operations; joint reception, staging, onward movement, and integration; joint logistics over the shore; and joint petroleum over the shore. TS23 also provided USARPAC and AMC with the opportunity to establish an equipment set in Bandiana, Australia, as a precursor to the longer-term establishment of an enduring Logistics Support Area in Queensland.

“The Soldiers, civilians and contractors that embody our entire sustainment enterprise showed their resilience, know-how and warfighting support skills in a joint and multinational demonstration of AMC’s capabilities. I could not be prouder of our team,” Hamilton said.

The Chief of Staff of the Army recently tapped AMC to pilot the Rapid Removal of Excess aimed at increasing equipment-on-hand readiness through focused fielding, lateral transfers and divestiture.

The pilot is underway at Fort Liberty, North Carolina, and Fort Stewart, Georgia, where Soldiers from active units across both installations have been turning in items ranging from small electronics and general supplies to military vehicles.

“The R2E pilot is a critical part of the effort to unburden Soldiers from excessive equipment accumulated over 20 years of war,” said Mohan. “It will go a long way toward setting conditions for Regionally Aligned Readiness and Modernization Model and future modernization.”

Transforming Sustainment Warfighting Function in Support of 2030-2040

AMC is on a continuous path to synchronizing its efforts with all stakeholders across the ASE to deliver Sustainment Warfighting Capabilities in support of the Army and Joint Force of 2030 and 2040.

Military aid facilitated by AMC is making its way to Ukrainian battlefields at an unparalleled pace – sometimes within days, instead of the months or years that foreign military sales cases can historically take.

A key piece of this effort to support U.S. partners and allies is AMC’s Security Assistance Command, which had a record-breaking FY23, transferring $35.8 billion in new foreign military sales – ultimately providing critical defensive capabilities for allies and partners across the globe.

“The ASE continues to prove its operational value with crucial, time-sensitive support to Ukraine with staging, loading and transporting materiel halfway around the world. Sustainment and logistics have always been the strategic advantage of our Army, and that continues to be true on the world stage today,” said Hamilton.

Data

Data, which is now viewed as a new form of ammunition, is nested in every AMC line of effort.

Over the last year, the command’s Analysis Group has developed several cutting-edge tools within the AMC Predictive Analytics Suite to solve problems in support of U.S. and partner and allied operations that incorporate data from multinational partners, including Ukraine.

“It’s clear to me that data-enabled decisions will decide future battles,” Hamilton said. “The right data, at the right time, at the right place, will enable faster and better decisions at echelon, and allow us to out-think and out-pace any adversary.”

Forward looking

With the command’s vision postured to support a global joint force with modernization that transcends traditional boundaries, AMC will continue to underscore its commitment to building a resilient, agile, and technologically advanced force.

“We have the best logisticians in the world, and the feedback I get from our top generals serving around the world is they could not be successful without logistics, and specifically, without Army Materiel Command,” said Gen. James McConville, 40th Army Chief of Staff.

Social Sharing