Fort McCoy, Wis., was established in 1909. Here is a look back at some installation history from October 2023 and back.

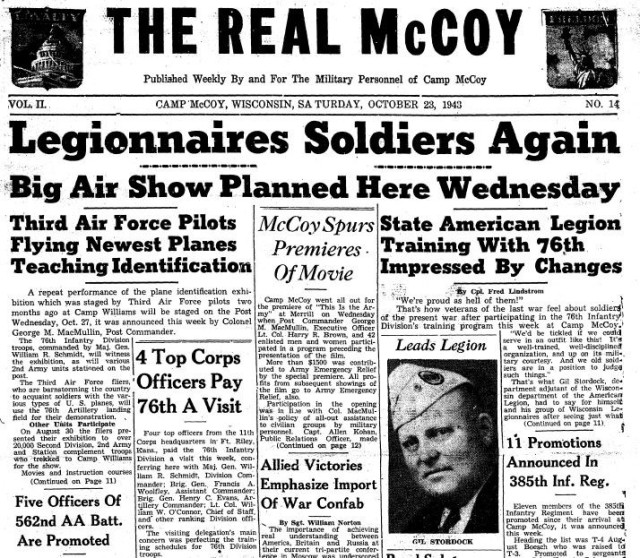

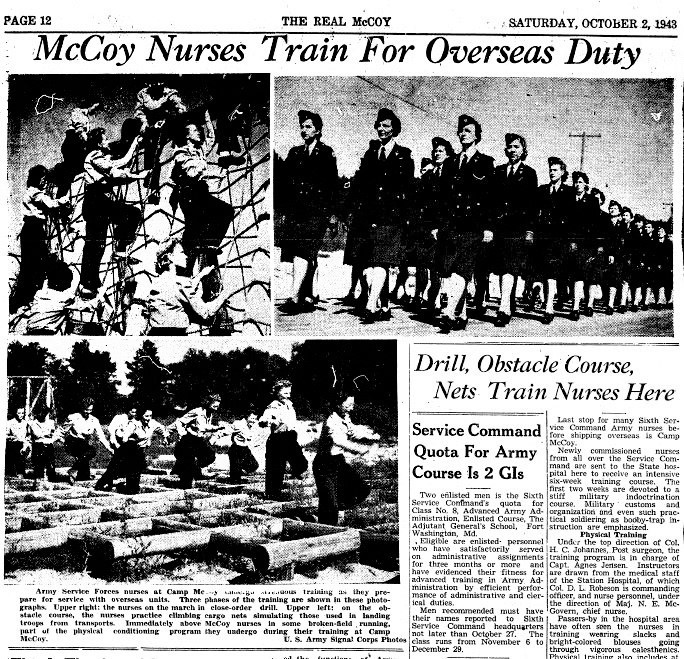

80 Years Ago — October 1943

FROM THE OCT. 2, 1943, EDITION OF THE REAL MCCOY NEWSPAPER: Big post laundry boasts outstanding safety score (By Pvt. Leo Kissel) — There’s one place in Camp McCoy where even the officers take a back seat to the enlisted men, and where civilians, who have already tightened their belts to see that Uncle Sam’s fighting men get a square deal on food, bend forth even greater efforts to keep the Soldiers in clean clothes.

It’s the million-and-a-half dollars quartermaster laundry, one of the finest establishments of its kind in the nation.

Firm in the belief the men fight better in clean clothes, the laundry here — and in camps throughout the nation — offers the Soldier the best bargain he can acquire either in civilian or military life.

Fine safety record

There hasn’t been a major accident in the plant since its inception almost a year ago. Lt. Day points out the camp’s unit is well arranged, roomy, and has the most modern equipment. This safety record is remarkable considering most of the equipment is of the hazardous nature.

FROM THE OCT. 23, 1943, EDITION OF THE REAL MCCOY NEWSPAPER: Signal unit aids combat outfits here — T'he efficiency of combat units in fighting zones and training areas is helped by the work of the Signal Corps, and Camp McCoy’s Signal Corps section merits a superior-plus rating for its performances.

The McCoy signal section is one of the many activities which are the responsibility of Col. George M. MacMullin, post commander. This section is a part of Col. H. F. Wilkinson’s Supply and Service Division, and is under the direct supervision of Maj. Thomas L. Williamson.

Recently Maj. Gen. Harry G. Ingles, the Army's chief signal officer, commented: “We can’t stress that there can ever be too much training of Signal Corps personnel.”

Commended by Gen. Robertson at Camp McCoy, the communications and signal supply units are doing their jobs splendidly, as can be evidenced from the recent commendation given the section's units by Maj. Gen. Walter M. Robertson, 2nd Infantry commander. One of the main functions of the signal section at McCoy is to maintain and repair all communications equipment used by combat forces stationed here.

This includes transmitters of the frequency modulation and amplitude modulation types and communications receivers. All movie projectors used on the post are also repaired in the shop. The latest precision instruments are used by repair shop workers.

Master Sgt. Edward C. Koehler, a veteran of 22 years in the Army, directs repair shop operations. Sgt. Koehler has helped install shops throughout various other commands. The McCoy unit was activated January of this year, but real operations got underway in March, when Sgt. Koeler arrived with equipment from Fort Sheridan’s inactivated unit. There are five civilians employed in the shop, as well as five Soldiers.

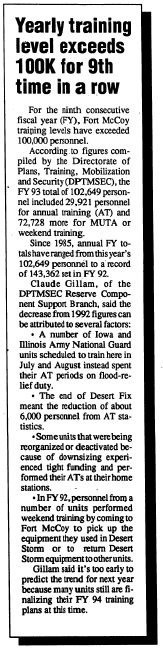

30 Years Ago — October 1993

FROM THE OCT. 8, 1993, EDITION OF THE TRIAD NEWSPAPER: TRA IN(ing)! Du Pont's CAER Cars, staff help local HAZMAT teams build response skills (By Rob Schuette) — Hazardous material response personnel from throughout the county and across the region showed they were up to the challenge Sept. 29 when they successfully contained a simulated chlorine gas leak from a railroad car at Fort McCoy.

The “disaster” was the final test in a three-day training course sponsored at Fort McCoy by the Du Pont Corporation. Fort McCoy and the Monroe County Local Emergency Planning Committee hosted the three-day seminar, which was attended by about 100 personnel.

Among the personnel were representatives of the Monroe County Hazardous Materials Response Team; local fire departments; the Wisconsin Department of Natural Resources; the Environmental Protection Agency Region 5 and the state of Minnesota's Fire Marshal’s office.

Steve Stokke, an environmental management specialist from the post’s Environmental Management Division, said the training is in such demand that it had to be scheduled a year ahead of time.

In the training, Du Pont uses CAER (Community Awareness and Emergency Response) Cars and instructors to help emergency response personnel become familiar with spills, leaks and just about anything else that can go wrong with a chemical tanker car.

Dale Yust, the lead Du Pont instructor for this training scenario, said Du Pont offers the training to increase awareness of the circumstances surrounding a potential hazardous material incident.

“We find that most of the personnel have a lot of book or classroom knowledge,” he said. “But we offer them hands-on training that shows them what would happen, and what they would have to do in an emergency.”

FROM THE OCT. 22, 1993, EDITION OF THE TRIAD NEWSPAPER: Post to test soy/diesel fuel (By Public Affairs Staff) — Starting Monday, Nov. 1, Fort McCoy will be the General Services Administration

(GSA) operational test site for soy/diesel fuel for one year.

Directorate of Logistics (DOL) Energy Coordinator/Conservation Officer Terry Nolan was able to convince the U.S. Department of Agriculture (USDA), sponsor of the test, and GSA, that Fort McCoy, with its distinctive four-season climate, is the best site to test this environmentally important fuel.

This is a significant event — one that could propel Fort McCoy and GSA into the forefront in the use of alternative fuels in conjunction with large vehicle fleets, said George Chaconas, Fort McCoy Director of Logistics.

Soy/diesel is a compound fuel, made of up to 40 percent pure oxygenated soybean oil. The oil is mixed with other fuels, notably various grades of diesel fuel. A strong selling point is no vehicle mechanical conversions are needed.

‘You just fuel up and go,” Nolan said. Environmentally, vehicle emissions are lowered by 70 percent, and the oil has a less toxic nature, similar to shampoo.

Nolan said he first heard about the fuel in June while attending the Alternative Fuel Conference in Milwaukee. He became intrigued by the fuel’s very nature.

20 Years Ago — October 2003

FROM THE OCT. 24, 2003, EDITION OF THE TRIAD NEWSPAPER: Training totals top 130,000 mark (By Public Affairs Staff) — Fort McCoy training totals for fiscal year 2003, which ended Sept. 30, topped the 130,000 personnel trained mark for the fourth consecutive year.

Of the 130,950 personnel trained, 42,452 personnel were here for two-week annual training, and 88,498 personnel were here for weekend training.

Barbara Rezin and Claude Gillam, Directorate of Training, Mobilization and Security Training Division, said the training statistics included 14,746 personnel who were mobilized and/or deployed through Fort McCoy to support various contingencies, including Operation Iraqi Freedom and Operation Enduring Freedom.

The number of troops mobilizing through Fort McCoy was a factor in the number of troops training at Fort McCoy little more than 7,200 troops from fiscal year 2002 total’s of 138,203 personnel trained.

FROM THE OCT. 24, 2003, EDITION OF THE TRIAD NEWSPAPER: World War Il-era truck company makes return visit to McCoy (By Public Affairs Staff) — Almost 60 years later to the day, members of a World War II unit that deployed from then-Camp McCoy returned to visit the installation.

The 3626th Quartermaster Company (Truck) was at McCoy from April 1-Oct. 1, 1943.

A group of about 15 veterans and their family members visited Fort McCoy on Oct. 3 as part of a tour through the area. The group served in the European Theater of Operations.

Unit members, now mostly in their late 70s to 80s, started holding reunions in 1948, said Ruth West, Fort McCoy Community Relations assistant. The group has gathered regularly throughout the years and came to Fort McCoy and the surrounding area this year.

West said, according to a unit representative, it was the first time the unit had held a formal reunion at Fort McCoy since it left in 1943. Most of their reunions have been in the southern part of the country. Although some of the group had since returned to visit Fort McCoy, at least several of veterans in the group had not been at McCoy since their unit left in 1943.

5 Years Ago — October 2018

FROM THE OCT. 12, 2018 EDITION OF THE REAL MCCOY NEWSPAPER: Ammunition supply Soldiers enhance skills, expertise in ALC at McCoy (By Scott T. Sturkol) — Nearly a dozen “89-Bravos” from Army units across the country completed training in the 89B Advanced Leader Course (ALC) at Fort McCoy from August to September with the 13th Battalion, 100th (13th, 100th) Regiment.

An ALC is a branch-specific course that provides Soldiers selected for promotion to staff sergeant an opportunity to enhance leadership, technical skill, tactical expertise and experience needed to lead squad-size units, according to the Enlisted Personnel Management Directorate of Army Human Resources Command.

An ALC consists of both a 90-day highly facilitated web-based common core program and a branch-specific resident phase. For the 89B ammunition specialist military occupation specialty, its ALC at Fort McCoy is four weeks (two two-week phases).

“This is the second fiscal training year we’ve had the ALC here at Fort McCoy, and it’s going well,” said Sgt. 1st Class Doug Dobitz, course coordinator with the 13th, 100th. “In this course, future enlisted leaders in this MOS build their skills to not only become better leaders and supervisors, but also better Soldiers.”

Soldiers who are 89B-qualified are tasked with receiving, storing, and issuing conventional ammunition, guided missiles, large rockets, explosives, and other ammunition and explosive-related items. During the two phases of the course, the students learn about advanced leadership and supervision skills required for their career field and more.

According to the Army job description, ammunition supply specialist NCOs supervise the receipt, storage, issue, and preparation of ammunition, ammunition components and explosives for transportation and storage. They also supervise ammunition stock control and accounting procedures for surveillance inputs, conduct ammunition inspections and tests, and perform inspections of containers and vehicles transporting ammunition.

89B NCOs also inspect storage locations, ensuring compliance with storage compatibility, quantity distance, and explosive safety limits. And, they ensure compliance with all ammunition safety requirements as prescribed in applicable Army regulations.

Fort McCoy’s motto is to be the “Total Force Training Center.”

Located in the heart of the upper Midwest, Fort McCoy is the only U.S. Army installation in Wisconsin.

The installation has provided support and facilities for the field and classroom training of more than 100,000 military personnel from all services nearly every year since 1984.

Learn more about Fort McCoy online at https://home.army.mil/mccoy, on Facebook by searching “ftmccoy,” and on Twitter by searching “usagmccoy.”

Also try downloading the Digital Garrison app to your smartphone and set “Fort McCoy” or another installation as your preferred base. Fort McCoy is also part of Army’s Installation Management Command where “We Are The Army’s Home.”

Social Sharing