A new eye irrigation device being developed with the assistance of the U.S. Army Medical Research and Development Command could someday help doctors and medics save the eyesight of Warfighters exposed to harmful chemicals on the battlefield.

Chemical burns to the eye are one of the few ocular emergencies that, if not treated quickly, can cause a complete loss of eyesight. According to the Cochrane Database of Systematic Reviews, up to 22% of ocular trauma is caused by contact with chemicals. Flushing the eyes with water is the most common and effective immediate response, but even the most advanced ocular irrigation systems aren’t always able to penetrate deep enough to cleanse the whole eye. Furthermore, many systems require a specialist to operate them – a challenge for treating Warfighters in combat situations and other austere environments.

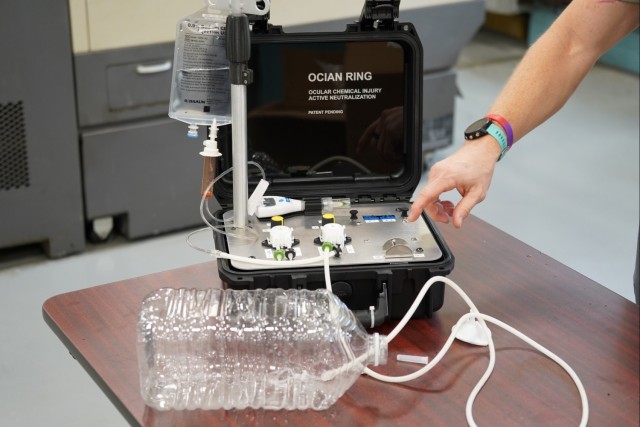

Dr. Gregory Giles, an ophthalmologist specializing in cataract and refractive surgery at the Brooke Army Medical Center at Joint Base San Antonio, Texas, saw the need for a rugged, portable device that doctors and medics could use to provide deep eye irrigation to injured Warfighters. He invested his own time and capital to create a prototype machine that he calls the Ocular Chemical Injury Active Neutralization Ring. The centerpiece of the OCIAN Ring is a thin and flexible intravenous tube with a loop at one end perforated with small window-like holes, like a garden soaker hose. The other end of the tube is connected to a small pump. When the loop is placed under the patient’s eyelids and the pump is switched on, water flows through the loop, carefully washing chemicals and particles from around the eye. The ring’s design allows it to clean the whole eye, especially the delicate tissues at the base of the eyelids called the fornices, which many other irrigation devices miss. The OCIAN Ring also incorporates a pH meter that allows the operator to test whether any residual chemicals remain around the eye.

Seeking assistance to develop his invention beyond the prototype stage, Dr. Giles submitted his design to MRDC’s Medical Technology Transfer Office, which coordinates intellectual property licensing to help DOD inventors successfully commercialize their products for the Warfighter. MTT uses a process it developed called Assistive Technology Transfer, or AT2, which involves working with inventors to systematically mature and de-risk their biomedical technologies to the point that they are ready for licensing by commercial partners. The AT2 process ensures that the first-generation products that reach the Warfighter are mature and military ready.

Ron Marchessault, a technology transfer professional with MTT, explains that the de-risking process involves investing revenue it receives through earned royalties from licensing other inventions into the design and construction of prototypes, seeking design input from Defense Health Agency clinical and regulatory experts and identifying additional potential funding sources such as angel and venture capital investors and economic development groups.

“First we look at the appropriate sector within the medical market that the technology would be germane to,” says Marchessault. “Then we look at the subsectors within the sector that the technology will be utilized. We also look at the technology itself: What commercial potential does the technology have? Then we look at the state of development the technology is in. Is it more specific or sensitive than available commercial products? Does the invention advance what’s already out there in the marketplace? If it's at least equal to or better than available products, then that increases the probability of licensing.”

To help improve prototype development advancement, Marchessault reached out to MRDC’s Medical Materiel Development Activity for assistance developing a commercially viable version of Dr. Giles’ prototype OCIAN Ring. MTT has an interagency agreement that allows USAMMDA’s Medical Prototype Development Lab to provide design, fabrication, evaluation and testing services for invention prototypes, as well as repairs and enhancements to existing products, components and systems. The OCIAN Ring is one of the first inventions receiving this type of engineering assistance for advanced prototype development.

The lab developed a prototype that fits all the components – pumps, battery pack, controls, intravenous tubing and pH meter – into a rugged, easily transportable case roughly the size of a briefcase. In addition to helping the lab’s engineers to test and refine the design, the prototype also serves as a technology demonstrator that Marchessault can take with him to tech showcases, professional conferences and other events where he can demonstrate it to potential commercial partners.

“The ocular health care market is a billion-dollar market, and we know the OCIAN Ring is going to fit a small subsector within that overall market,” Marchessault explains. “So, we want to look at all the competitors in that space, and once we identify a certain number of companies within that market sector, we target them for potential interest in licensing the invention.”

To date, MTT has used the AT2 process to bring more than 20 biomedical products like the OCIAN Ring – vaccines, therapeutics, diagnostics, medical devices and medical software – to market, with many more currently in various stages of development. Although success in technology transfer is traditionally measured in terms of patents, licenses and royalties, MTT also measures its success in terms of the number and quality of products made available to Warfighters and the public. MRDC’s AT2 pipeline has proven to be a sustainable way to produce new biomedical products and technologies that improve the medical and health outcomes of the Warfighter and the public.

Social Sharing