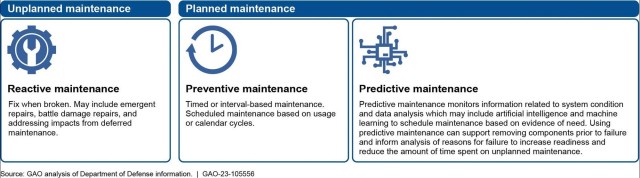

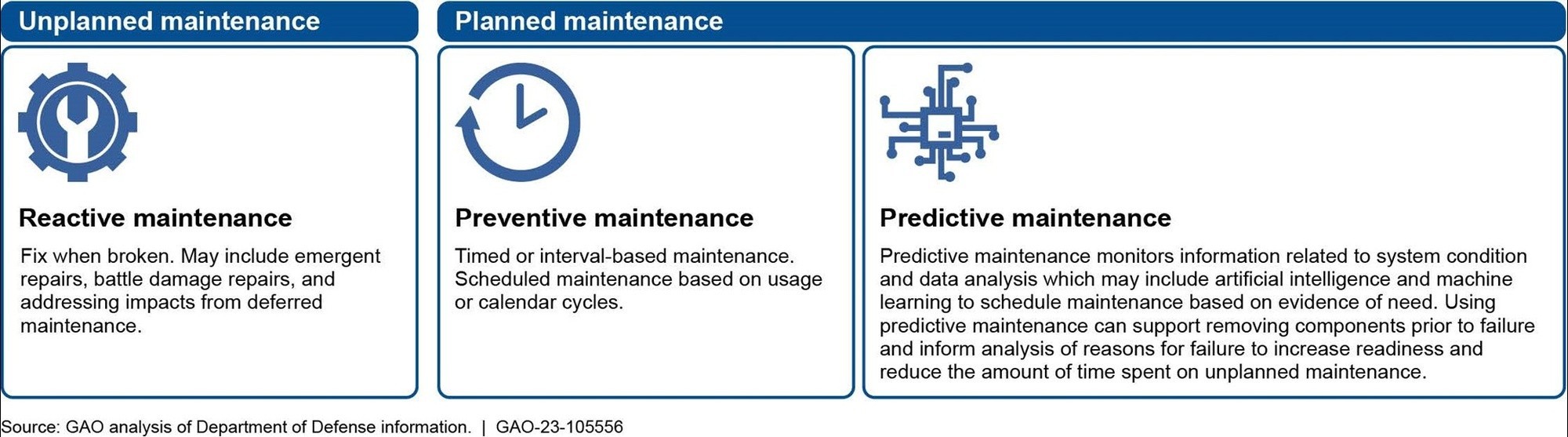

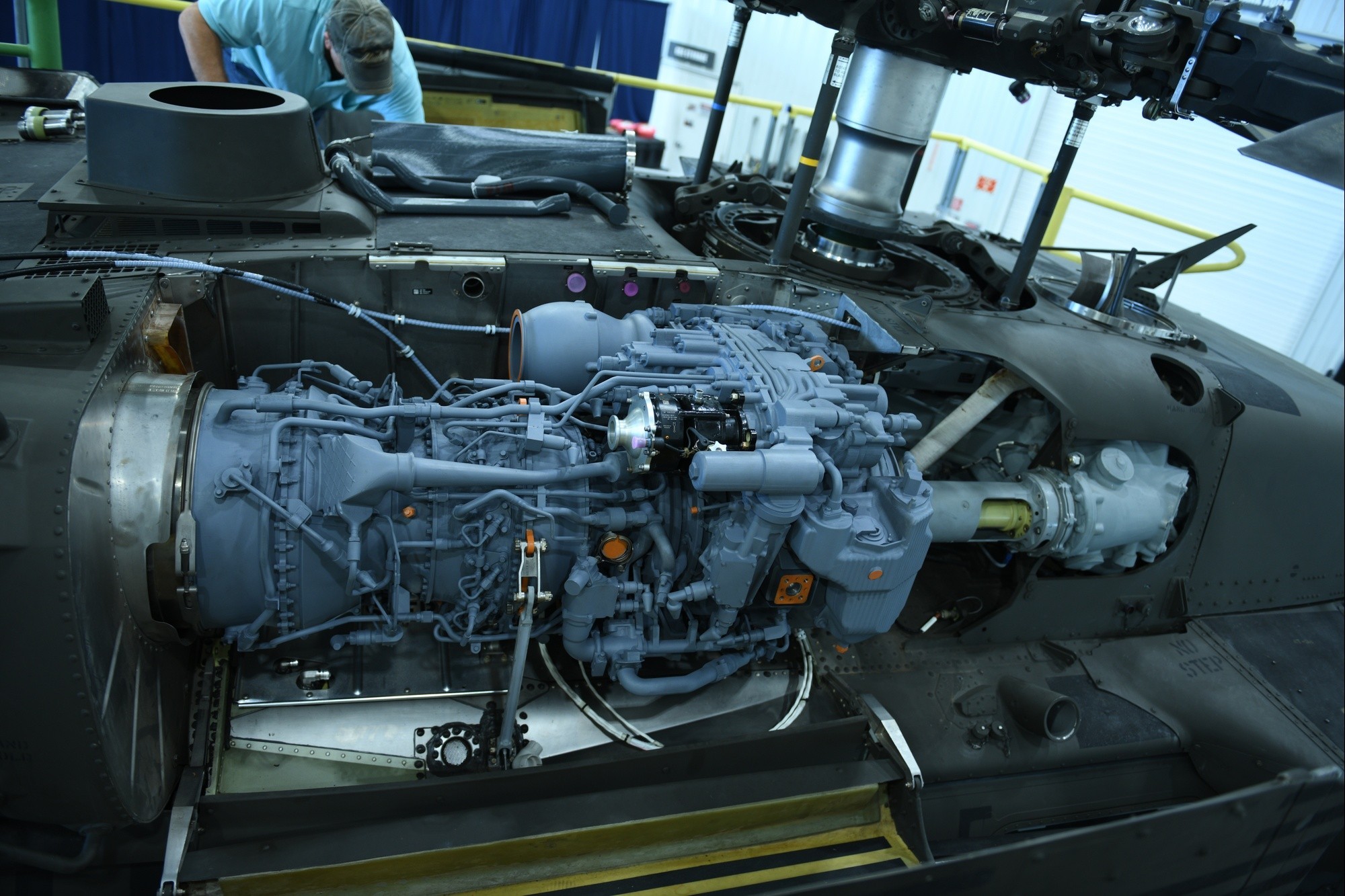

The Army has designed the T901 Improved Turbine Engine to be compliant with Prognostic and Predictive Maintenance (PPMx) technologies. PPMx, a predictive maintenance strategy based on relevant data, helps to increase operational readiness by identifying potential maintenance issues and part failures before they occur. An extensive array of sensors which enable this technology outfit the T901’s many components. The T901 is the new 3,000 shaft horsepower engine designed to fit within the current engine mounting, nacelle and installation envelope of the AH-64E Apache and the UH-60M Black Hawk helicopters. It will replace the current T700-GE-701D engine and will also power the Future Attack Reconnaissance Aircraft (FARA).

The T901, with its onboard PPMx system known as Engine Health Management System, or EHMS, supports DoD Instruction (DoDI) 4151.22 (Aug. 14, 2020): Condition-Based Maintenance Plus for Materiel Maintenance. DoDI 4151.22 describes Condition Based Maintenance Plus (CBM+) as a shift in maintenance behavior and practices enabled by technology that focuses on condition monitoring, proactive predictions and automated failure analysis as well as future data-driven insight. With CBM+ (now known as PPMx), Army maintainer personnel are better equipped to anticipate future component failures. They can perform proactive and predictive maintenance at the most opportune times and locations using the correct parts and tools, while prolonging the time on wing for specific components.

PPMx features of T901 also support the Army Climate Strategy (ACS) Line of Effort 2: Acquisition and Logistics. T901 engines contain components that provide self-diagnosis and automated maintenance alerts. This capability is a key driver for employing the advanced technology of anticipatory logistics in reducing sustainment demand. Additionally, associated Greenhouse Gas emissions will be reduced by optimizing parts inventories and gaining supply chain efficiencies brought about by using PPMx.

The T901 engine’s PPMx system allows increased technology and added functionality, which will enable Army Aviation the necessary capability to apply, integrate and improve reliability and maintenance effectiveness on both the enduring and future fleets of helicopters. PPMx will enable proactive engine maintenance that is planned around critical missions. This will increase Army Aviation’s capability in the form of maximized reliability.

The ATE Project Office is one of nine Program Executive Office, Aviation project offices. Located at Redstone Arsenal, Ala., the ATE PO is responsible for centrally managing the Army’s rotary wing turbine engine and electrical power capability for U.S. Army Aviation and coalition partners. Cindy Mitchell is an Avion Solutions employee supporting the Aviation Turbine Engines Project Office in operations.

Social Sharing