REDSTONE ARSENAL, Ala. — The U.S. Army Test, Measurement and Diagnostic Equipment Activity, known as USATA, is one of the most critical organizations in the Army, yet it is also one of the least understood and often underfunded.

USATA certifies the accuracy of test, measurement and diagnostic equipment, and it supports every weapons system used throughout the Army — not just aviation and missile assets — even though it is a subordinate element of the Aviation and Missile Command.

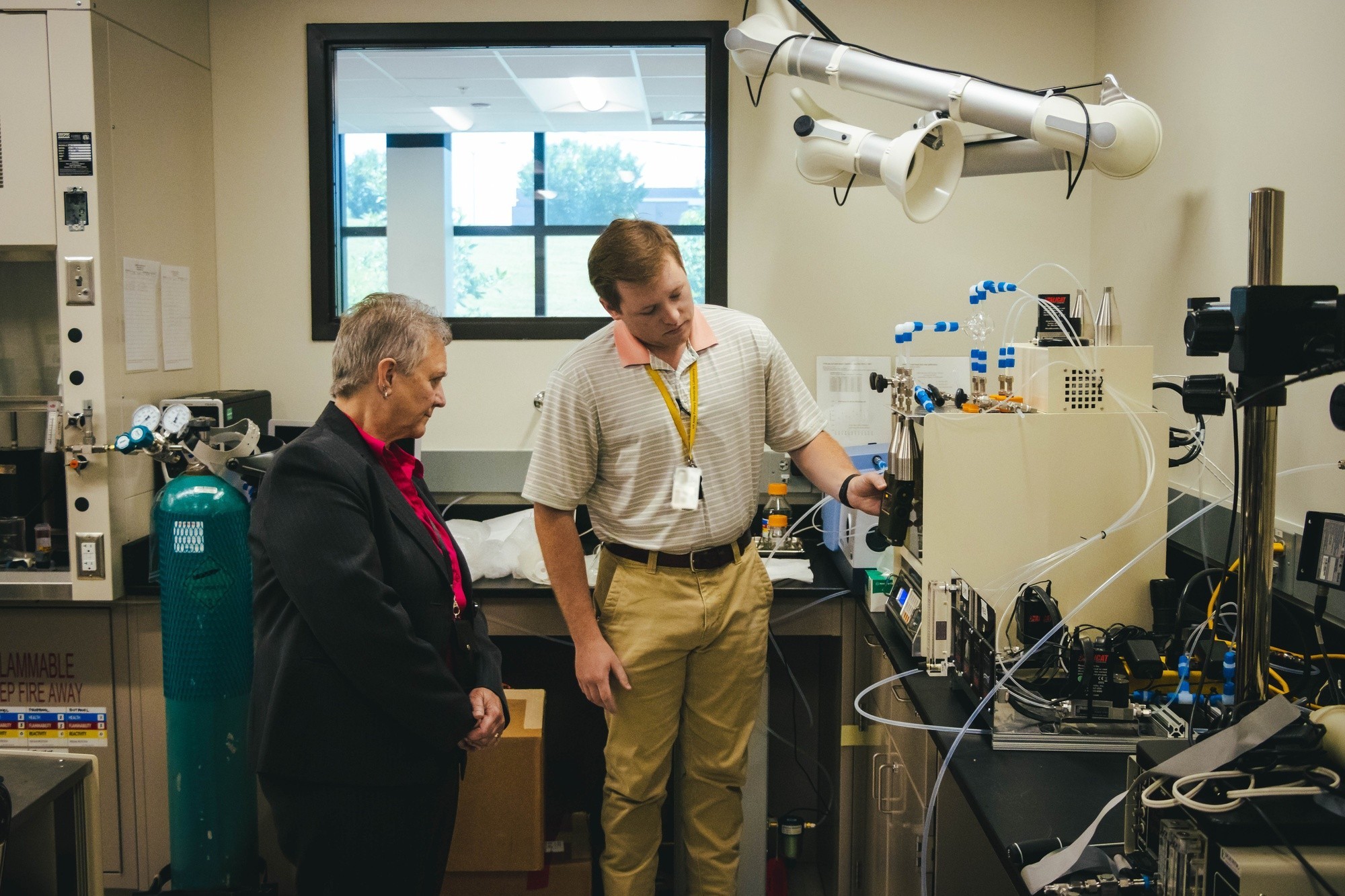

To champion their need for more funding, USATA Director David Hargett and AMCOM Commander Maj. Gen. Tom O’Connor welcomed Army Materiel Command Executive Deputy to the Commanding General Marion Whicker to USATA headquarters Aug. 14.

During her visit, Whicker received a tour of the Army Primary Standards Lab, where she witnessed firsthand some of the cutting-edge technology used to keep the Army running. However, it was during the organization overview briefing that Hargett and O’Connor were able to drive home the importance of funding the mission.

O’Connor said he wanted Whicker to understand the resource challenges facing USATA due to its enterprise-wide reach.

“Everything from the tactical units to the depots has some sort of calibration requirement,” he said. “But, because it belongs to everybody, it’s easy to say it doesn’t belong to anybody, and no one wants to pay for it.”

USATA supports more than 850,000 test, measurement and diagnostic equipment — or TDME — items across the force structure, ensuring weapons system readiness at 42 locations worldwide, and it is integrated with Army Futures Command signature modernization efforts for next-generation weapons system support.

USATA provides measurement trust for sustainers to meet Army platform readiness demands and they write the standards and calibration procedures for each piece of TMDE, all of which are vetted by engineers. They also audit area TMDE support teams, the U.S. Army Medical Materiel Development Activity calibration laboratories, National Guard combined support maintenance shop teams and the USATA civilian calibration teams to ensure they all comply with the standards needed for traceability of all calibration measurements made in the Army.

“We also provide nucleonic and radiation dosimetry services,” Hargett said. “We have records that go back to 1954. We know every Soldier who has been exposed to radiation, and we can tell how much they’ve been exposed to.”

USATA provides engineering and logistics support for every piece of TMDE the Army fields. Their engineers, equipment specialists and logisticians receive a calibration and repair requirements worksheet and determine if and where those items can be supported in the enterprise.

Hargett said USATA works with the project office or developer for items they cannot support and receives funding for newly fielded systems since they do not have the standards to calibrate those items.

He said his biggest challenge is securing an enduring resource line of funding for calibration instrument modernization to adequately support the TMDE enterprise across the operating and generating force — that is where he needs assistance.

Whicker listened, took notes, gave suggestions and ultimately assured the team that she is on their side and ready to fight for their funding, but she needs their help with messaging.

“There is a lack of understanding when it comes to calibration,” Whicker said. “Most people, when they think of calibration, they think of gapping a spark plug. We have got to talk to them about this equipment. And, as we go to more modern equipment and the calibration requirements increase, you have to get people to understand what calibration equipment is and why it’s critical to readiness. Help me articulate that.”

To see more photos from the tour, visit the U.S. Army Aviation and Missile Command Flickr.

Social Sharing