Instructors at the U.S. Army Signal School’s Information Technology Development College (ITDC) are doing their part to not only train the Army’s newest Signaleers, but they are doing it in such a way that is undisruptive while the installation undergoes transformation.

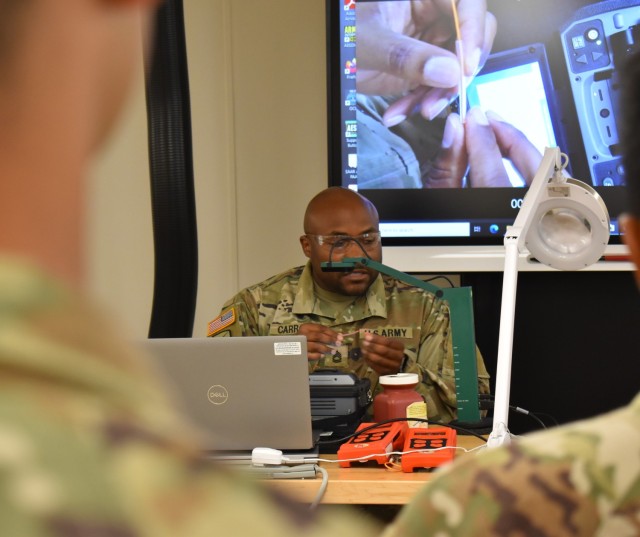

Students enrolled in the ITDC’s Network Communication System Specialist (25H) Course spend a portion of their core training in mobile fiber labs thanks to the ingenuity of their instructors; most of them former cable systems installers (25L).

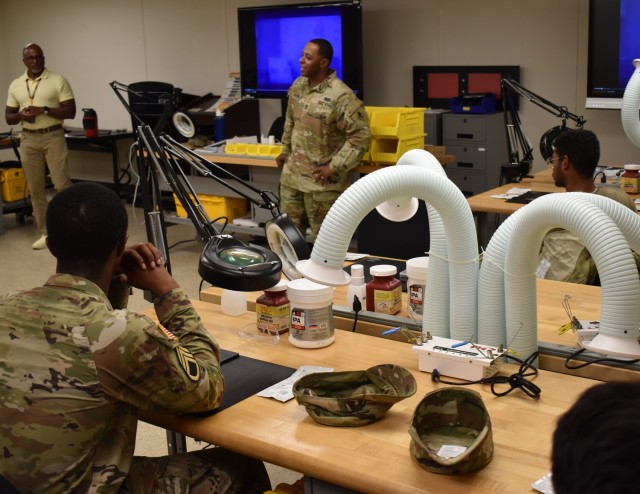

Located inside the Vincent Hall Relocatable Barracks (VRLB), mobile fiber labs “can be easily moved from one location to another, providing greater flexibility and adaptability for training,” said Rodney Wells, Tactical Transmission Switching Branch, Tactical Training Division.

Wells went on to explain that “the fiber labs are designed to be user-friendly, making it easier for both instructors to use the equipment effectively,” by allowing them “to conduct training sessions in various environments and settings. This versatility means that training can occur anywhere across Fort Gordon.”

Designed in response to the significant growth and transformation on Fort Gordon, the labs were located at Ponderosa training site (which has since closed) prior to being moved to the VRLB, where they will remain until renovations at Brant Hall are completed. More than 1,400 Soldiers have trained on the mobile labs since their implementation at Ponderosa last year.

Currently, two labs are fully assembled and in use, with an additional two on the way.

“We are in the process of getting more equipment to be able to open remaining two labs,” said Darnell Husband, 25H instructor, U.S. Army Signal School.

In addition to facilitating more efficient training, the mobile labs contain added safety features such as mobile eyewash stations, air filtration systems, and fume extractors.

“With the fume extractors that we just purchased, they were usually in the ceiling, but now they are underneath the desks, and these are safety measures by being able to move,” Husband said. “And it saves money by not having to reinstall them each time we move.”

Overall, feedback has been very positive from those impacted by the course.

“It has been a big help for the instructors, because they are the ones who are having to move the equipment around, and I think the command likes it because they don’t have to worry about continuously having to [submit] work orders and things of that nature to take out equipment and reinstall it,” Husband said.

With an emphasis on “easy maintenance,” the labs are designed to remain operational with minimal downtime, if any.

“They ensure that trainees can focus on learning without distractions or discomfort,” Wells added.

Social Sharing