College students will now be able to reach new innovative heights during the latest partnership to hit Fort Stewart’s Marne Innovation Center. The National Security Innovation Network now offers a 10-week summer internship for engineering students who apply for the X-Force Fellowship Program.

“The National Security Innovation Network has been a partner for a little over a year now,” said 3rd Infantry Division innovations officer Capt. Chris Flournoy. “They partner with us to assist with resources and experts needed to help Soldiers solve their problems.”

This is the first year that the Marne Innovation Program is partnering with the X-Force to give students an opportunity to work with the Department of Defense.

Alison Beatty, a regional engagement principle from the National Security Innovation Network, explained that the idea to incorporate the X-Force summer fellowship program came from former Marne Innovations team lead, Capt. Chris Aliperti.

“He identified two projects for which [the fellowship] would be a perfect fit,” Beatty said. “He and I held a few virtual meetings to scope initiatives into projects that were the right size to tackle in a 10 week period.”

The X-Force fellowship program is a summer paid-internship for both undergraduate and graduate students. During the program, students have the unique opportunity to work alongside the U.S. Department of Defense to address real-world challenges while making a contribution to National Security by addressing real-world challenges.

The program identifies current capability gaps within 3rd Infantry Division and then works with industry and academic partners to rapidly identify, develop, and implement solutions while fostering a culture of bottom-up innovation; solving today's problems with today's technology.

Currently, the Marne Innovation Center is working with two, two-person collegiate teams to design two unique devices. One team is focused on a 3D printed arm that will be used as a medical training aid. The second team is focused on creating an electromagnetic spectrum emitter, which is used to replicate a U.S. Army Bradley vehicle.

“We are trying to create something that is cheap and disposable and is easy for Soldiers to take out to train with,” Flournoy said. “Having these interns is beneficial because they come in with new ideas, and have a different perspective than what a Soldier might have day in and day out.”

Joseph Ashley, a student from Georgia Tech, conducted research by talking to medics and Soldiers from Tactical Combat Casualty Care classes and was able to implement what they would like in their course.

“The biggest request from Soldiers was tourniquet applications,” said Cole Malenich, a student from Georgia Tech. “We decided to create a 3D printed arm that you can apply a tourniquet to, as well as pack wounds.”

The 3D arm has a bullet wound, stab wound, a gash, and a tube going through the inside that represents an artery. As you apply the tourniquet it should stop the arm from bleeding.

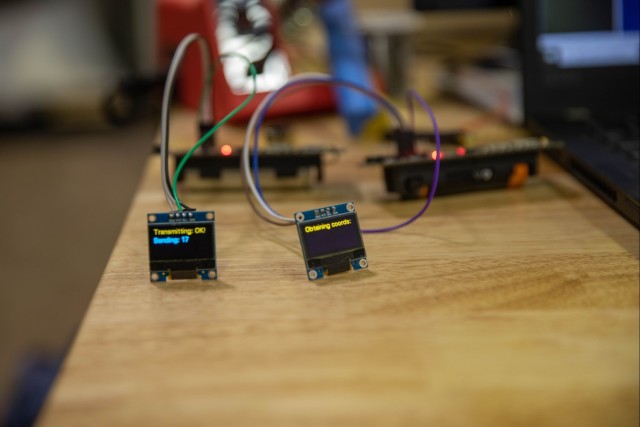

Joseph Peterson, a student from Purdue University, and Alina Miles, a student from Ohio Northern University, created the user-friendly electromagnetic spectrum emitter decoy. This device broadcasts different frequencies that bounce around and was created to be a tactical decoy to throw off the enemy.

“The idea behind this is to be able to imitate the U.S. Army Bradley,” Peterson said. “The goal is to emulate the frequencies and the frequency hopping they use to correct power output.”

Ideally, the device will change about 100 frequencies per second with a battery life of up to three days. The team hopes that the project will bring electromagnetic warfare to the next level and if done in time, could be used at the National Training Center in August.

These projects have potential to greatly benefit the military and students are able to receive real world experience and apply it to their project. This internship allows students to apply what they learned in the classroom to real-world situations. By working in this environment it helps students enhance their skills, gain insight, and learn about their engineering practices.

Social Sharing