REDSTONE ARSENAL, Ala. — The Army is currently in year two of its largest modernization planning effort in nearly forty years, with the goal to overhaul and update its organic industrial base over the next 15 years.

To keep that process on track, the OIB task force meets biannually to identify, prioritize and review requirements and efforts. Known as the OIB Modernization War Game, the fifth meeting was held at Redstone Arsenal, Alabama, in the Aviation and Missile Command headquarters June 13-15.

Leaders from depots, arsenals and ammunition points throughout the Army gathered to share ideas and challenges, as well as provide updates.

In addition to tracking the ongoing initiatives and requirements, the task force also focused on funding, which includes finding alternative mechanisms to fund projects, such as partnerships with industry and academia.

“We are working with manufacturing innovation institutes to see industry best practices and how those can be incorporated into government operational standards and policies,” said Stephanie Hoaglin, deputy director of the task force. “We want to ensure we are ready for tomorrow’s fight, not just today’s.”

The commander of Army Materiel Command, Gen. Charles Hamilton, echoed Hoaglin’s comments.

“We have to figure out a better way to work with industry — to give them the predictability and make the right investments in the defense industrial base,” he said.

Regarding the OIB, which he called “the nation’s insurance policy,” Hamilton told the task force the onus is on everybody in the room, including him, to hold one another accountable and ensure they meet the modernization milestones without falling into the status quo or becoming complacent.

The Army’s OIB is charged with manufacturing, sustaining and resetting Army equipment, generating readiness and operational capability worldwide, such as the Army’s support to the current ongoing conflict in Ukraine.

Hoaglin said while OIB modernization efforts are not new, the recent momentum started in late 2021 with the creation of the task force and a 15-year plan to prepare for the Army of 2030 and beyond. She said the war games held in the fall and spring are critical, but they are not the only collaborative efforts and touchpoints across the OIB enterprise. Her team hosts weekly meetings with the Life Cycle Management Commands and visits the individual sites to see firsthand what is needed.

When visits are not practical or when a site needs to showcase larger efforts to the entire task force, they utilize technology. Day one of the war game showcased some of that technology.

Luke Martin, AMCOM deputy G4, gave the task force an up-close and personal view of one of his projects, hangar renovation at Corpus Christi Army Depot.

Martin manages modernization efforts for AMCOM. He said while they have multiple subject matter experts, he focuses on the bigger picture. One of AMCOM’s main projects is the CCAD modernization strategy, which includes renovating and updating four existing hangars and building an aircraft remanufacturing facility.

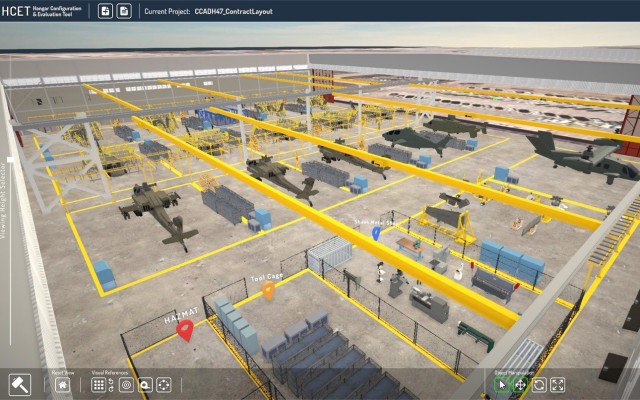

Martin demonstrated the hangar configuration and evaluation tool, which took the group on a virtual tour of Hangar 47 — a 77,000-square-foot facility in southeast Texas. The tool’s capability is similar to a simulation video game, allowing the user to place aircraft, electrical drops, toolboxes, and even personnel on the hangar floor to ensure adequate spacing and requirements needed to accommodate the enduring fleet, as well as future aviation assets.

“Models like this allow us to not only plan for our current workload but also understand our future workload and any variations that may come our way,” Martin said. “For instance, it provides us the ability to see how many outlets the artisans need when they work on the aircraft. Then my designers know to drop power or air or a data port or a Wi-Fi port — whatever it is, we can build them into this tool and simulate everything before we ever shovel dirt.”

Martin’s demonstration of the hangar configuration and evaluation tool started conversations about the software and its capability to be shared across the OIB enterprise, which is one of the benefits of meeting in person — to collaborate and learn from each other.

“This is a great opportunity because I can talk with people from all the different aspects of modernization across the OIB,” he said. “As Gen. Hamilton said, we know we are the insurance policy for the nation, and we are trying to plan, not only for our current efforts, but also incorporating the things we need to modernize as the Army moves forward into 2030 and 2040. The whole process shows us where we are, where we need to improve and how we need to rebuild our OIB.”

Social Sharing