The thornier the problem, the more collaboration, shared knowledge, and teamwork it takes to solve it.

The latest example of this kind of collaboration is the U.S. Army’s specialized working group created to specifically take on the use of hexavalent chromium known as Cr6+ -- a highly effective, non-corrosive agent used in multiple weapons systems but has been shown to be a human carcinogen.

Specifically titled the Acquisition and Logistics Heavy Metals Sub-Working Group, the team was charged with reducing the exposure to Cr6+ for U.S. Army civilian employees and soldiers, Army-wide. The team not only created several policy and procedural processes to take immediate action, but also laid the groundwork for the ultimate elimination of all heavy metal exposure.

“The team’s accomplishments are numerous and will pay great dividends in the short- and long-term,” said Ms. Amy Borman, Deputy Assistant Secretary of the Army for Environment, Safety and Occupational Health in the office of the Assistant Secretary of the Army for Installations, Energy and Environment.

“This group not only created an immediate reduction in exposures to Cr6+ at the depot and field level, but they have also done the hard work and critical thinking to allow the Army to start reduction and ultimately elimination of all heavy metals in our processes. That’s remarkable,” Borman said.

Borman added that this recent work is helping the Army to be even more ambitious in its planning going forward, and essentially to leapfrog where it has been in seeking to reduce Cr6+. For this work, the team was selected as a winner of the 2023 Department of Defense Environmental Awards.

“This team’s accomplishments and planning have laid the groundwork for Cr6+ elimination plans, policies, and processes that have been unattainable for over 20 years,” said Mr. Timothy Goddette, Deputy Assistant Secretary of the Army for Sustainability for the Office for ASA Acquisition, Logistics, and Technology.

“While complete removal of Cr6+ from our Army weapon systems will still take many years, these efforts and achievements have been instrumental in taking the first step to a greener, safer, and more resilient Army,” Goddette said.

The issue of long-term use of Cr6+ center on the toxicity of the substance to humans and the environment. Cr6+ is a known human carcinogen and can cause numerous cancers if not properly handled, managed, and controlled. Its utilization, management, and disposal are closely watched by regulatory agencies such as the Environmental Protective Agency and the Occupational Safety and Health Administration.

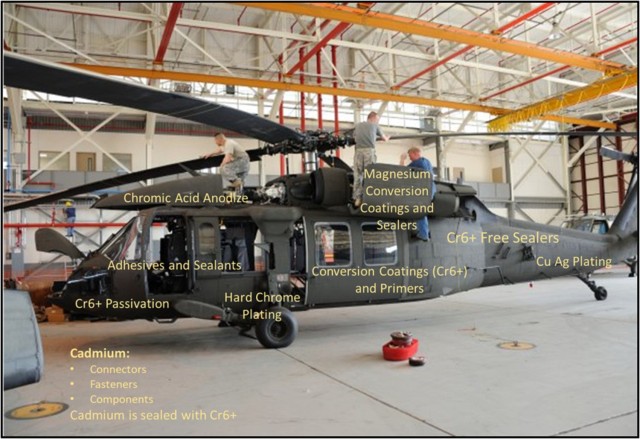

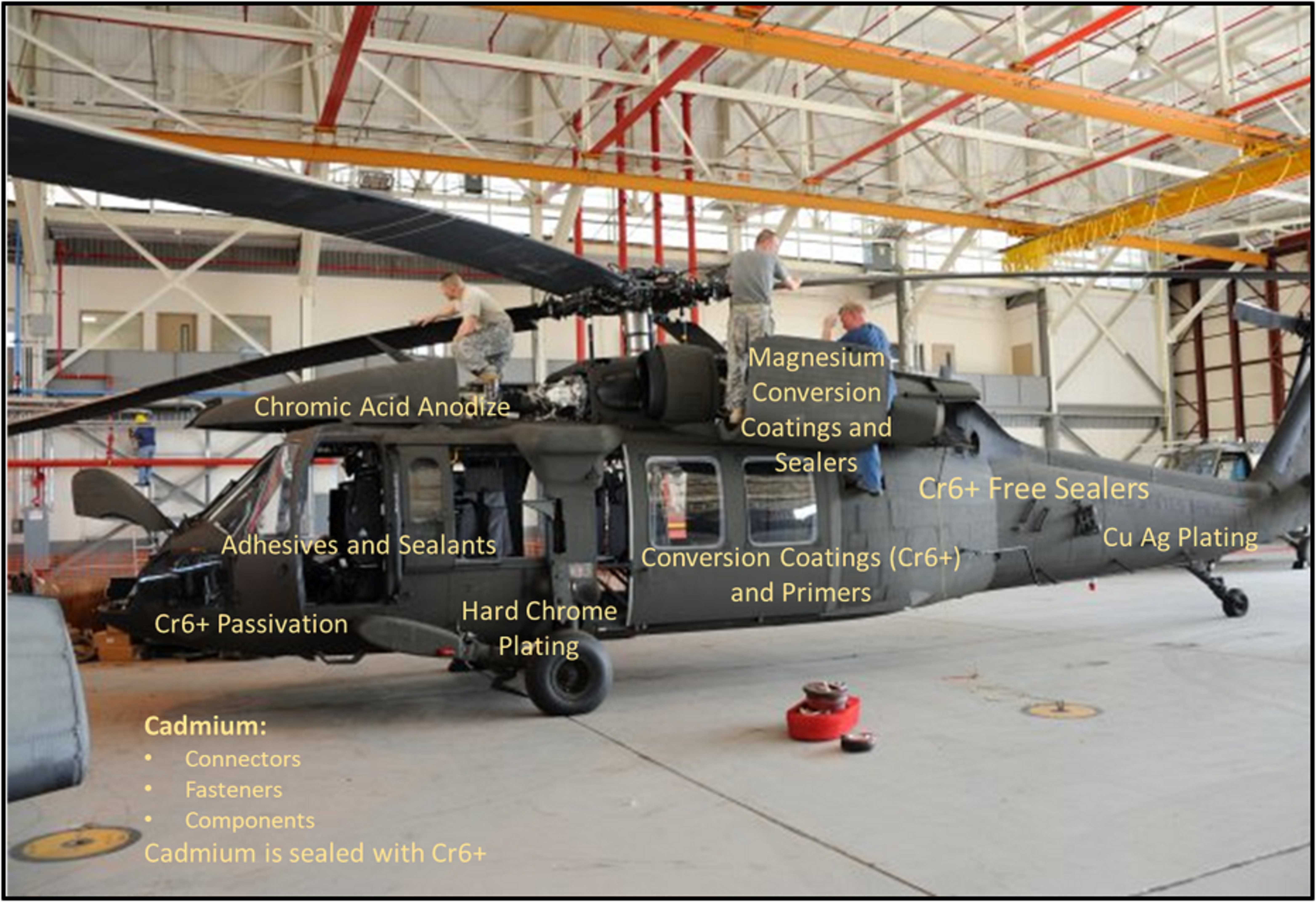

The substance, however, has been very difficult to replace as it is extremely effective in preventing corrosion – a key element in maintaining equipment and Army readiness. It has worked so well in this application that it helped extend the serviceability of many platforms beyond the original life expectancy. Therefore, many of the legacy weapon systems in the Army inventory designed in the 1960s and 1970s still contain Cr6+ and due to the complex and costly nature of finding suitable alternatives, new weapon systems have continued to incorporate Cr6+ into their design.

To untangle this, the team had to create processes that meet performance specifications, yet be less toxic to workers and the environment. The team created six charter tasks and took a deep dive into the myriad issues, procedures, processes, and performance standards that are part of the weapons system acquisition and repair processes.

One notable example was review and recommended creation of a specific “Elimination of Hexavalanet Chromium in Army Acquisition and Sustainment Policy,” which Goddette said “will eventually avoid sustainment costs.” The cost avoidance will come from changes and updates in worker safety engineering controls, protective equipment requirements, occupational health monitoring, special facilities for daily work decontamination, hazardous waste disposal costs, environmental permitting, possible fines, and required perioidic cleaning.

“The ability to match the overall goal with an incredibly tight focus on details sets this work apart,” said Ms. Marjorie McDonald, director of Safety and Occupational Health at the office of the ASA IE&E. “This is work that will make a difference and help create a safer and greener Army.”

Social Sharing