There’s no single, simple answer to meeting sustainability goals at a large, statewide organization.

By emphasizing the triple bottom line – mission, environment, and community – the Minnesota National Guard has produced tangible sustainability improvements and results in infrastructure and design, energy consumption and reduction, waste reduction, and water, and groundwater management.

“The sustainability team is the cornerstone of the MNNG’s long-term sustainability strategy; prioritizing resilience and independence to safeguard operations throughout the state,” said Lt. Col Troy Fink, Minnesota National Guard's chief of the Facility Management Office. “The team’s work has helped to slash waste and grow efficiencies across waste, water, and energy; their efforts translate into avoided costs and more effective use of MNNG funds to support the MNNG mission.”

Chief Warrant Officer 4 Justin Knippel, Minnesota National Guard’s Environmental Branch chief said one important example of the team’s impact is the construction of a microgrid using the solar arrays at Camp Ripley, a 53,000-acre training installation with incredible plant and animal habitat diversity. The project will allow for expanded use of alternative energy and is expected to help reduce the $5 million annual energy expense and dramatically increase the resiliency of the installation.

Another project at Camp Ripley has built three new stormwater infiltration basins that will capture 95% of stormwater runoff at the site — designed to capture 6.5 million gallons of water to allow for natural filtration of pollutants and protect water quality at the nearby Mississippi River.

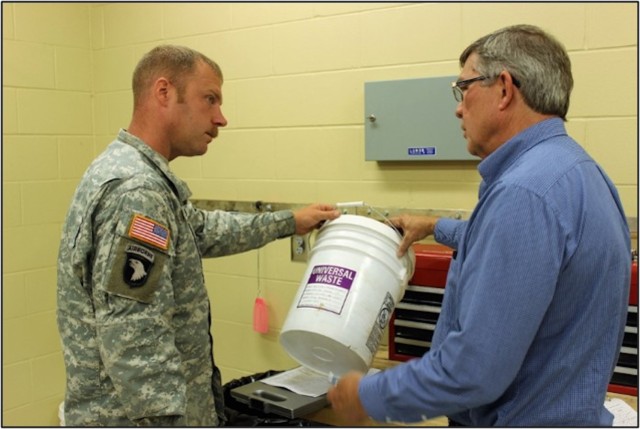

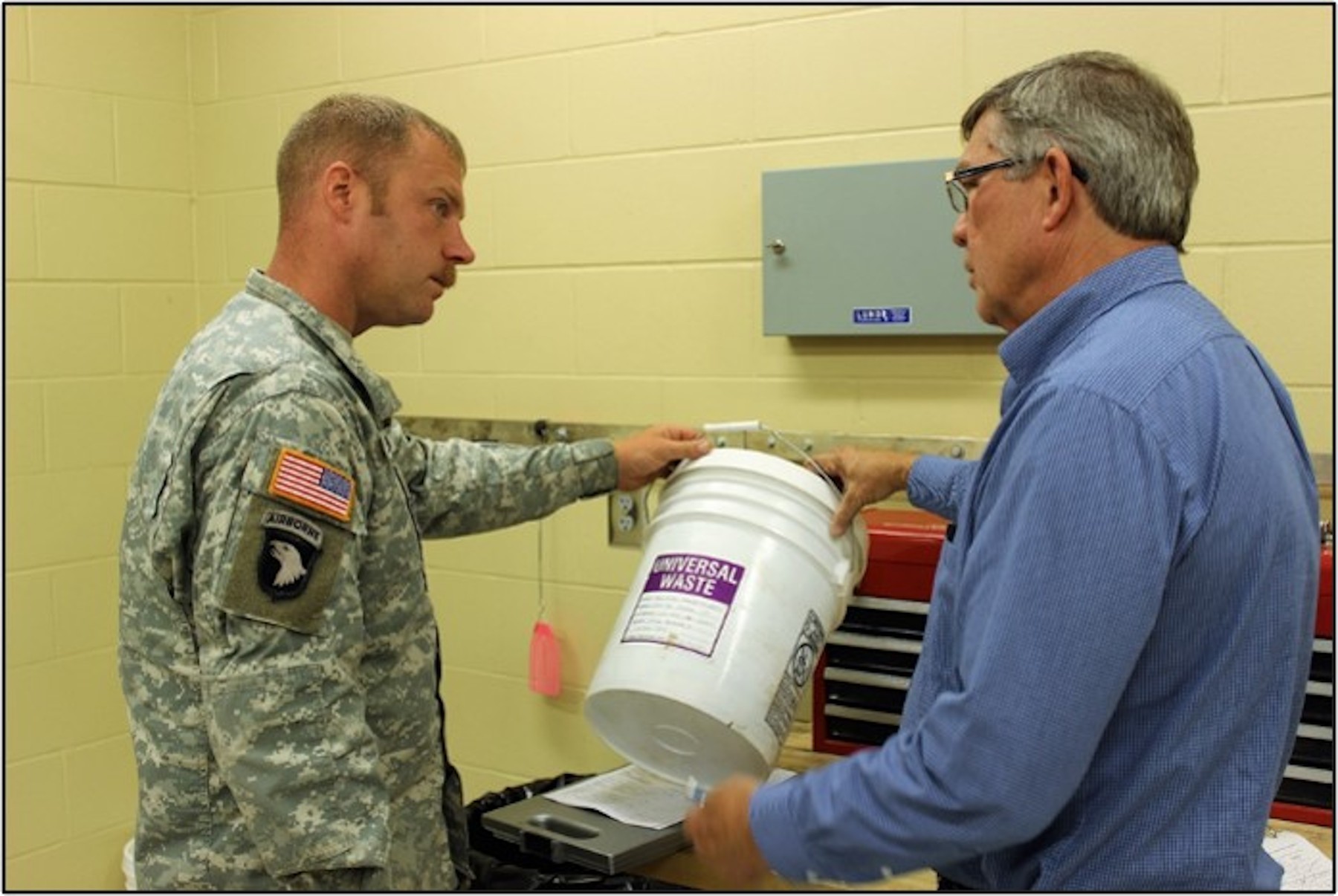

In addition to large-scale construction, the sustainability team has also developed “high-touch” procedures to provide information, procedural guidance, and policy explanation throughout MNNG units through the Site Assistance Visit for Environmental Requirements at all MNNG facilities.

“The SAVER teams can complete one-on-one training and resolve any issues a unit may be having. During these visits, they will spot-check dumpsters and review systems to ensure that recyclables are being recaptured and there are no indications of leaks or energy waste due to equipment issues,” said Lori Ruff Minnesota National Guard’s sustainability manager. “The sustainability team also coordinates both classroom and online environmental training to keep environmental compliance officers certified and ensure staff and soldiers have had the appropriate briefings.”

Other accomplishments at MNNG have included:

- In partnership with CenterPoint Energy, the sustainability staff has completed more than 30 energy audits at MNNG facilities throughout the state, identifying points for improvement and prioritizing upgrades to building envelopes and systems.

- To preserve the function of aging facilities and infrastructure, the sustainability team implemented a leak detection program that has saved millions of gallons of water over the past few years.

- Focusing on diverting organic waste from landfills through extensive composting programs supported a 40% diversion rate, diverting 40,000 pounds of organic material. The long-term goal is a 60% diversion rate.

Another innovation at MNNG is the creation of batch projects to make improvements on a 3- to 5-year timeline to improve sustainability at specific sites. Under this process, multiple sites will be outfitted with new boilers – allowing not only for discounted pricing from bulk purchasing but also creating 20% savings in energy use at each facility.

At St. Peter Armory, extensive mechanical and energy systems upgrades were installed in 2019. The improvements helped produce a 19.8% decrease in energy as well as a 4% cut in utility costs, despite increases in utility rates during that timeframe.

The renovations were comprehensive and included removing and replacing ventilation air systems, exhaust air systems, ceiling grilles, diffusers, and branch ductwork. These changes were accompanied with a new hot water boiler, pumps, variable frequency drives, heating water distribution piping, unit heaters, and an upgraded equipment control system.

Another project at Albert Lea Armory produced a 20.2% decrease in energy consumption from 2016 to today. This project focused on the building envelope to reduce waste and consumption, including installation of a new roof, new windows and insulation.

The data collected from the two very different yet effective projects is being used in ongoing sustainability work at armories throughout the state.

Social Sharing